Recyclable method for extracting and separating effective components of solanum nigrum

A technology of active ingredients and separation method, applied in the field of extraction and separation of active ingredients of Solanum nigrum, can solve the problems of inability to extract and separate, single extraction, etc., and achieve the effects of simple method, good reproducibility and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

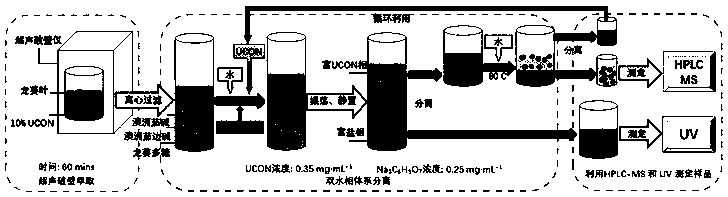

Image

Examples

Embodiment 1

[0030] A recyclable method for extracting and separating effective components of Solanum nigrum, the specific steps of the method are as follows:

[0031] (1), preparation of solanine standard solution: accurately weigh the standard substance (25mg) of solanine and solanine, put into 5mL volumetric flask respectively, dissolve with 3mL ethanol, and be settled to 5mL, A concentration of 5 mg·mL was obtained -1 Australian solanine and Australian solanine standard stock solutions. Then, take 2ml each of the storage solutions of the two single reference substances, put them into the same 10mL volumetric flask, and set the volume to 10mL to obtain a mixed standard solution of solanine.

[0032] (2) Preparation of glucose standard solution: Accurately weigh 10mg of glucose, place it in a 100mL volumetric flask, add 20mL of pure water to dissolve it, set the volume to 100mL, and obtain a concentration of 0.1mg·mL -1 glucose standard stock solution.

[0033] (3), Ultrasonic wall-br...

Embodiment 2

[0039] A recyclable method for extracting and separating effective components of Solanum nigrum, the specific steps of the method are as follows:

[0040] (1), preparation of solanine standard solution: accurately weigh the standard substance (25mg) of solanine and solanine, put into 5mL volumetric flask respectively, dissolve with 3mL ethanol, and be settled to 5mL, A concentration of 5 mg·mL was obtained -1 Australian solanine and Australian solanine standard stock solutions. Then, take 2ml each of the storage solutions of the two single reference substances, put them into the same 10mL volumetric flask, and set the volume to 10mL to obtain a mixed standard solution of solanine.

[0041] (2) Preparation of glucose standard solution: Accurately weigh 10mg of glucose, place it in a 100mL volumetric flask, add 20mL of pure water to dissolve it, set the volume to 100mL, and obtain a concentration of 0.1mg·mL -1 glucose standard stock solution.

[0042] (3), Ultrasonic wall-br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com