Method for SCR ammonia injection adjustment optimization based on full-load accurate denitration requirements

A full-load, denitrification technology, applied in control/regulation systems, instruments, adaptive control, etc., can solve the problem of ultra-low emission of unsuitable units, deep peak regulation of full-load denitrification, large deviation between NOx and net flue gas NOx, Ammonia injection adjustment system adjusts lag and other problems to achieve the effect of improving the accuracy of ammonia injection, avoiding control disorder, and accurately controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

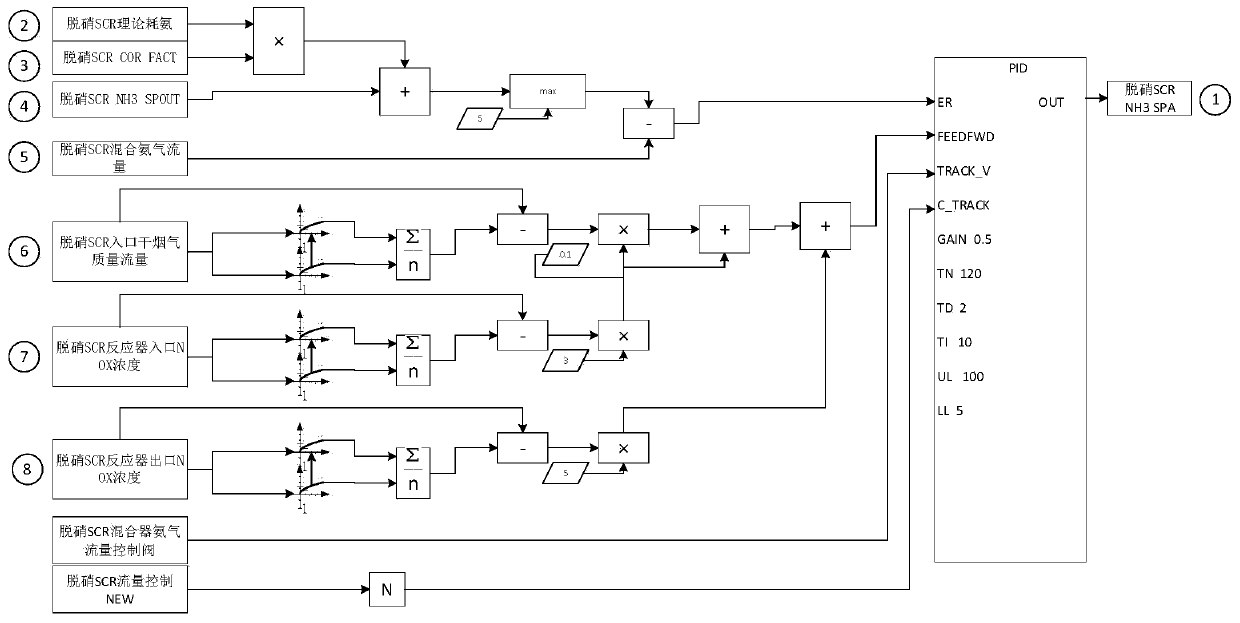

[0043] Example 1, such as Figure 1-Figure 5 As shown, a method for adjusting and optimizing SCR ammonia injection based on the requirement of full-load precise denitrification includes the following process steps:

[0044] The first step is to use the feed-forward signal of the change rate of boiler flue gas volume, NOx at the inlet of denitrification SCR, and NOx at the outlet of denitrification SCR to obtain the basic value of ammonia injection flow rate to meet the adjustment requirements of variable working conditions; among them, the boiler flue gas The volume is boiler fuel volume and total air volume;

[0045] The second step is to eliminate the anti-interference problem caused by adjusting the opening of the ammonia injection door with the ammonia injection flow rate as the adjustment amount;

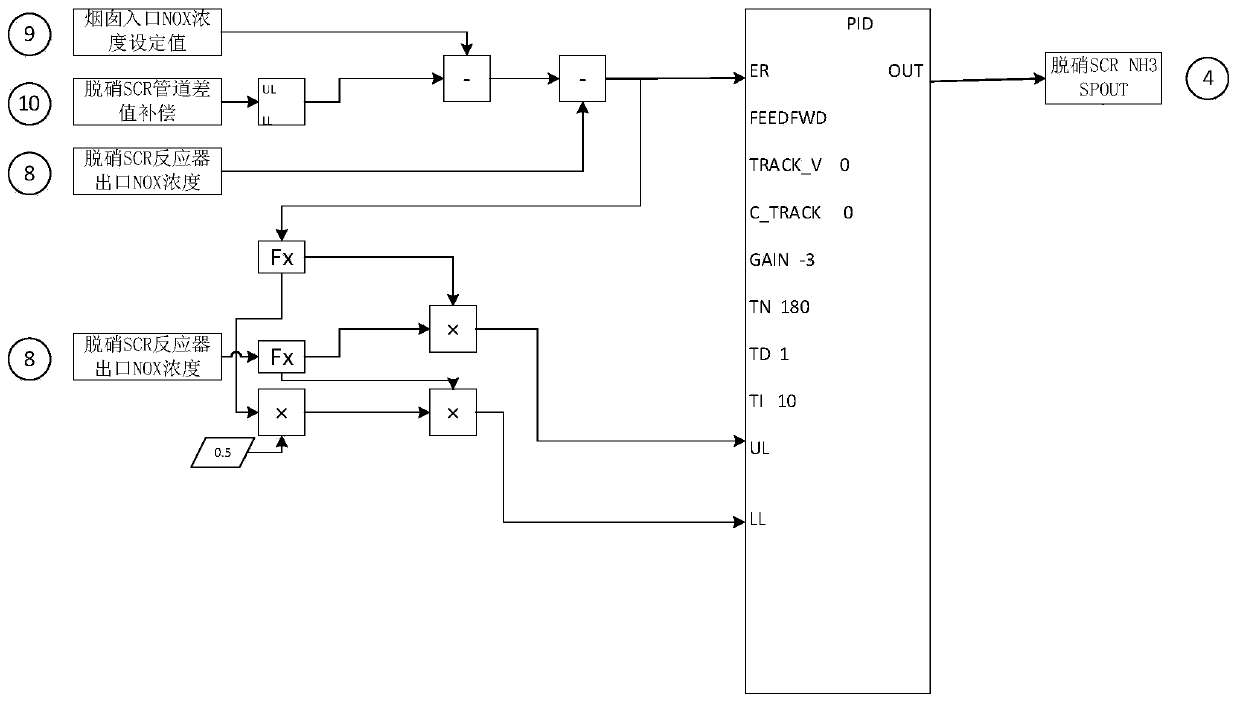

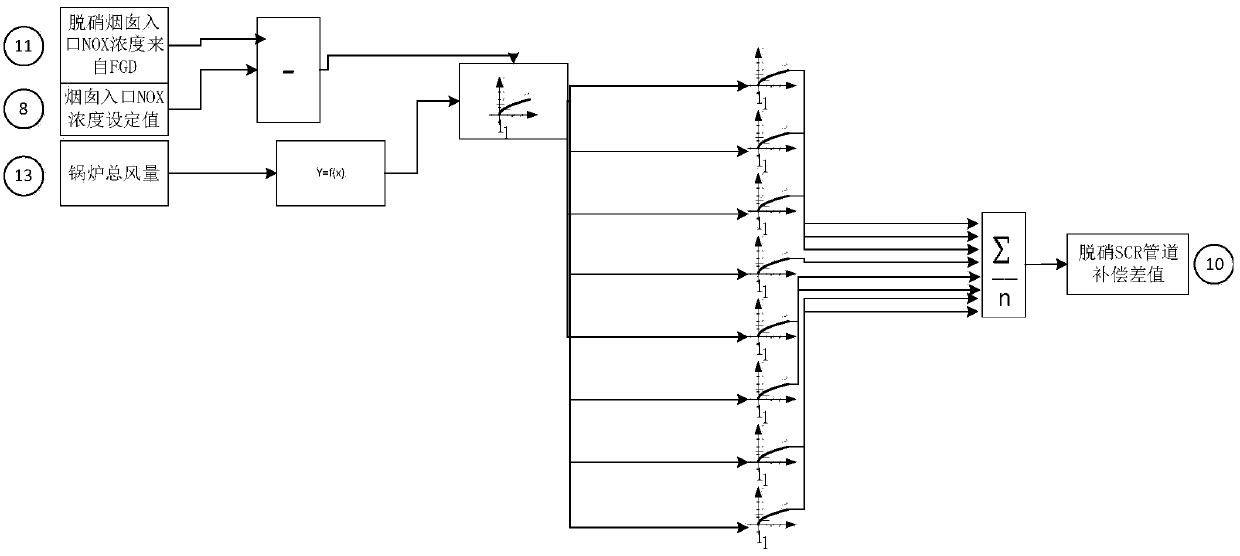

[0046] The third step is to establish the main adjustment loop with the hourly average NOx of the chimney net flue gas as the object, so as to meet the requirements of environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com