Premixed concrete mix proportion design method

A technology of ready-mixed concrete and mix ratio design, applied in the field of ready-mixed concrete, can solve the problems of high cementitious material consumption, uneconomical, concrete segregation, bleeding, etc., and achieve the effect of simple method and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

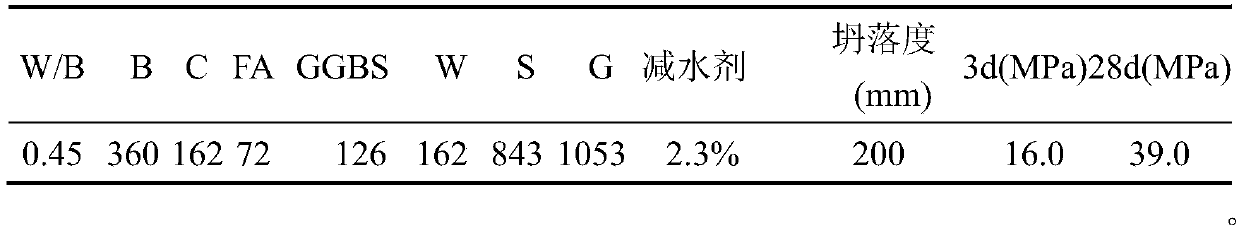

Embodiment 1

[0085] Requirements: Prepare C30 concrete, double-mixed with fly ash and slag powder, and the slump is above 180mm. Raw materials:

[0086] Cement: P.O42.5, apparent density 3050kg / m 3 ; Fly ash grade Ⅱ, apparent density 2200kg / m 3 ,

[0087] Slag: fluidity ratio 100%, apparent density 2900kg / m 3 .

[0088] Artificial sand: fineness modulus M X =2.8, sand in Zone II. Stone powder content 4%. Apparent density 2650kg / m 3 . The stone content is 6%, and the flake particle content is 8%.

[0089] Stone: crushed pebbles, close-packed porosity of 39%, needle flake content of 5%. Apparent density 2700kg / m 3 .

[0090] Water reducing agent: naphthalene series, solid content 31.5%.

[0091] calculation steps:

[0092] S1) Select the composition of the gelling material and the ratio of water to cement

[0093] The cementitious material is composed of 45% cement, 20% fly ash and 35% mineral powder. The water-binder ratio is selected as 0.45.

[0094] The water demand rati...

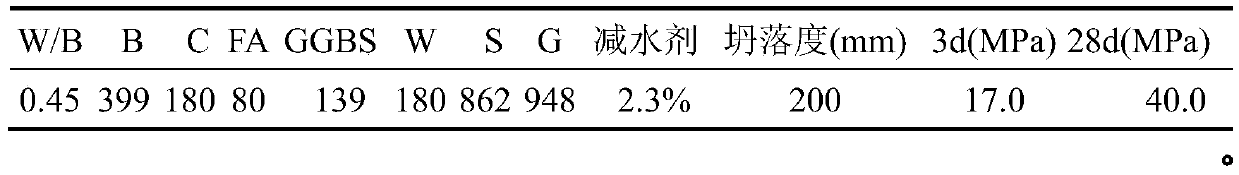

Embodiment 2

[0114] Requirements: Prepare C30 concrete, double-mixed with fly ash and slag powder, and the slump is above 180mm. Raw materials: cement: P.O42.5, apparent density 3050kg / m 3 , Class II fly ash, apparent density 2200kg / m 3 , slag fluidity ratio 100%, apparent density 2900kg / m 3 .

[0115] Artificial sand: fineness modulus M X =3.3, coarse sand in Zone I. Stone powder content 9%, MB value 0.75. Apparent density 2650kg / m 3 . The stone content is 30%, and the flake particle content is 23%.

[0116] Stone: crushed pebbles, closely packed porosity rate is 43%, and needle flake content is 6%. Apparent density 2700kg / m 3 .

[0117] Water reducing agent: naphthalene series, solid content 31.5%.

[0118] calculation steps:

[0119] S1) Select the composition of the gelling material and the ratio of water to cement

[0120] The cementitious material is composed of 45% cement, 20% fly ash and 35% mineral powder. The water-binder ratio is selected as 0.45. The water demand...

Embodiment 3

[0143] Requirements: Prepare C50 concrete, mixed with fly ash alone, and the slump is above 200mm.

[0144] Raw materials: cement: P.O42.5, apparent density 3050kg / m 3 , Class II fly ash, apparent density 2200kg / m 3 .

[0145] River sand: fineness modulus M X =2.4, sand in Zone II. The mud content is 7%. Apparent density 2650kg / m 3 . Stone content 5%.

[0146] Stone: crushed pebbles, close-packed porosity of 44%, needle flake content of 5%. Apparent density 2700kg / m 3 .

[0147] Water reducer: polycarboxylate high-efficiency water reducer, with a solid content of 15%

[0148] calculation steps:

[0149] S1) Select the composition of the gelling material and the ratio of water to cement

[0150] The cementitious material consists of 70% cement, 30% fly ash, and a water-binder ratio of 0.32. The water demand ratio of the gelled material was determined to be 98%.

[0151] S2) Calculate the amount of gelling material

[0152] Calculation of the amount of gelling mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com