Neodymium iron boron permanent magnet material and preparation method thereof

A permanent magnet material, neodymium iron boron technology, applied in the direction of magnetic materials, inductors/transformers/magnet manufacturing, magnetic objects, etc., can solve problems such as demagnetization, and achieve the goal of improving coercive force, temperature stability, and squareness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

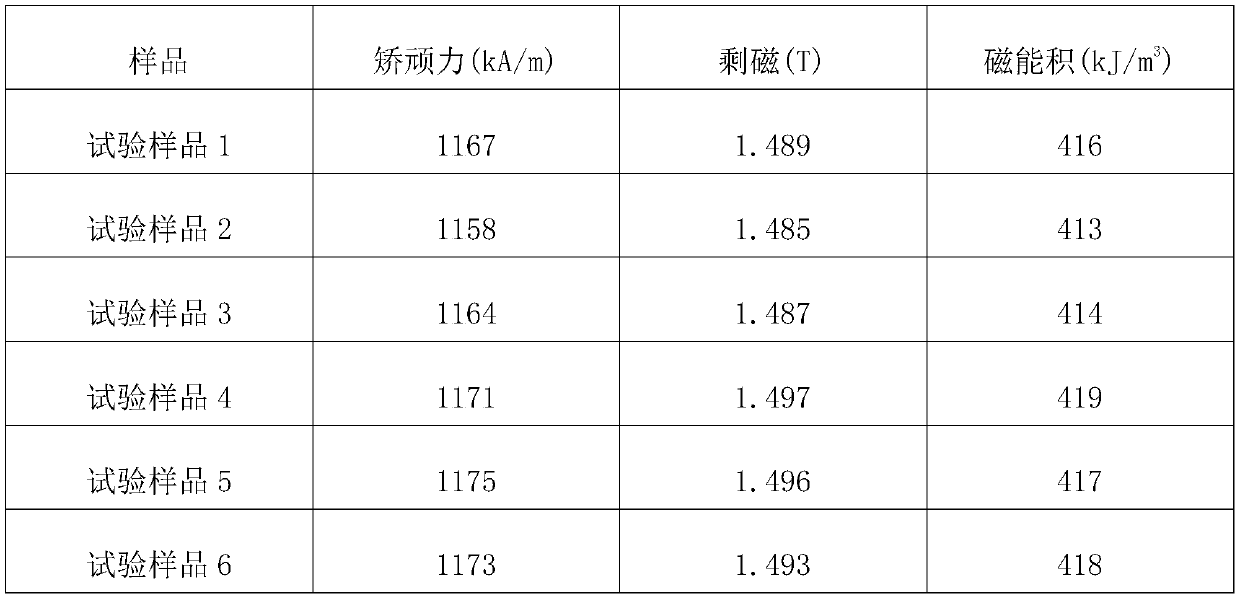

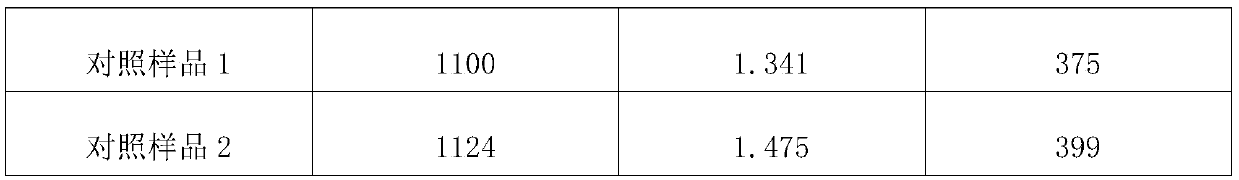

Examples

Embodiment 1

[0037] Embodiment 1: A kind of NdFeB permanent magnet material, the permanent magnet material comprises the following components by weight percentage: neodymium 30%, niobium 2%, cobalt 2.5%, zinc 0.15%, gallium 0.2%, boron 2.5%, tungsten 0.1% %, thulium oxide superfine powder 2.5%, and the balance is iron.

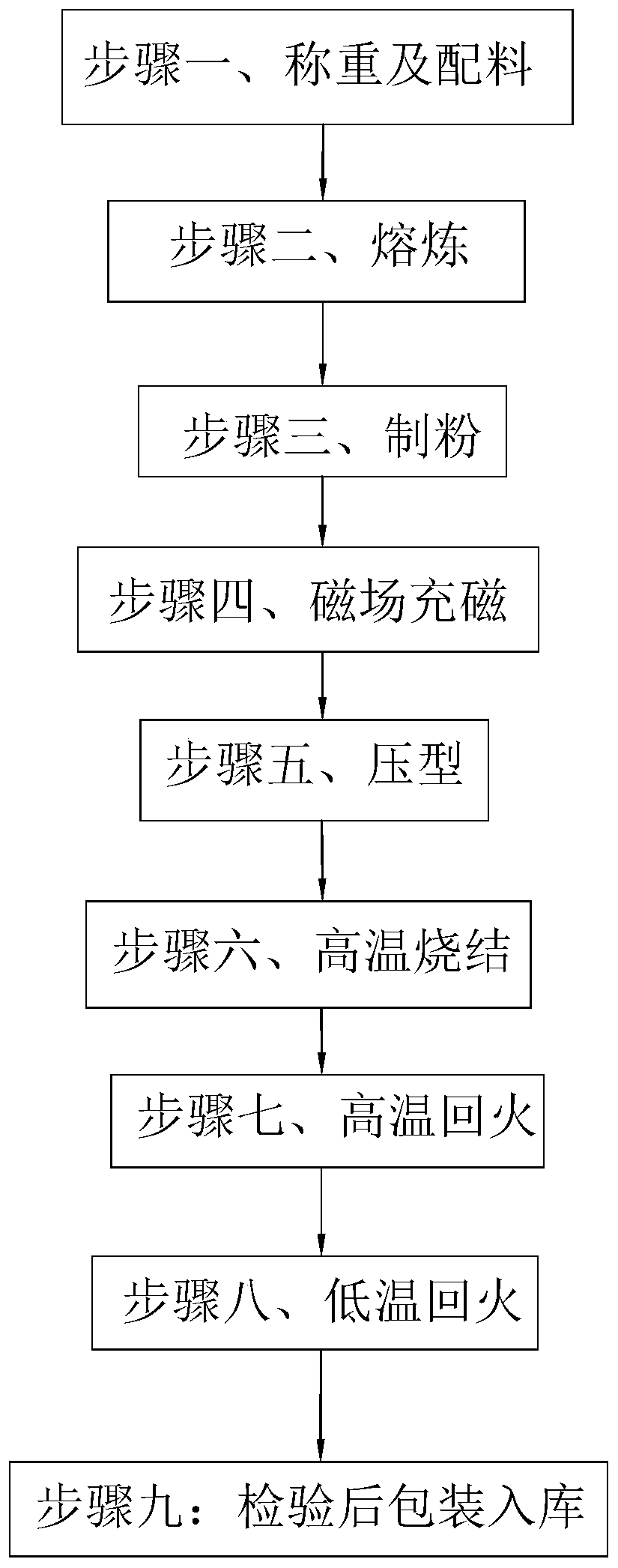

[0038] Its preparation method, such as figure 1 shown, including the following steps:

[0039] Step 1, weighing and batching: Weigh the following raw materials respectively, 30kg of neodymium, 2kg of niobium, 2.5kg of cobalt, 0.15kg of zinc, 0.2kg of gallium, 2.5kg of boron, 0.1kg of tungsten, 2.5kg of ultrafine powder of thulium oxide, iron 60.05 kg.

[0040]Step 2. Smelting: first put all the components in step 1 into the smelting furnace, then evacuate to below 1Pa, start heating, continue to evacuate (air) while heating, as the temperature rises, the gas in the adsorption state, The water is gradually desorbed and drawn out until the charge is generally dark red. Cl...

Embodiment 2

[0048] Embodiment 2: a kind of neodymium-iron-boron permanent magnet material, permanent magnet material comprises the following components by weight percentage: neodymium 36%, niobium 2.2%, cobalt 3%, zinc 0.18%, gallium 0.3%, boron 3%, tungsten 0.2% %, thulium oxide superfine powder 3%, and the balance is iron.

[0049] Step 1. Weighing and batching: Weigh the following raw materials respectively, 36kg of neodymium, 2.2kg of niobium, 3kg of cobalt, 0.18kg of zinc, 0.3kg of gallium, 3kg of boron, 0.2kg of tungsten, 3kg of ultrafine powder of thulium oxide, and 52.12kg of iron .

[0050] Step 2. Smelting: first put all the components in step 1 into the smelting furnace, then evacuate to below 1Pa, start heating, continue to evacuate (air) while heating, as the temperature rises, the gas in the adsorption state, The water is gradually desorbed and drawn out until the charge is generally dark red. Close the valve and fill with argon gas, increase the power to heat up to the com...

Embodiment 3

[0058] Embodiment 3: a kind of neodymium-iron-boron permanent magnet material, permanent magnet material comprises the following components by weight percentage: neodymium 45%, niobium 2.5%, cobalt 4.2%, zinc 0.2%, gallium 0.5%, boron 4.8%, tungsten 0.5% %, thulium oxide superfine powder 4%, and the balance is iron.

[0059] Step 1, weighing and batching: Weigh the following raw materials respectively, 45kg of neodymium, 2.5kg of niobium, 4.2kg of cobalt, 0.2kg of zinc, 0.5kg of gallium, 4.8kg of boron, 0.5kg of tungsten, 4kg of ultrafine powder of thulium oxide, iron 38.3 kg.

[0060] Step 2. Smelting: first put all the components in step 1 into the smelting furnace, then evacuate to below 1Pa, start heating, continue to evacuate (air) while heating, as the temperature rises, the gas in the adsorption state, The water is gradually desorbed and drawn out until the charge is generally dark red. Close the valve and fill with argon gas, increase the power to heat up to the compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com