An adjustable graphite milk spray system for friction presses

A technology of friction press and spray system, applied in the direction of spray device, etc., can solve the problem that the spray system of graphite milk cannot be adjusted, etc., and achieve the effect that the spray system can be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

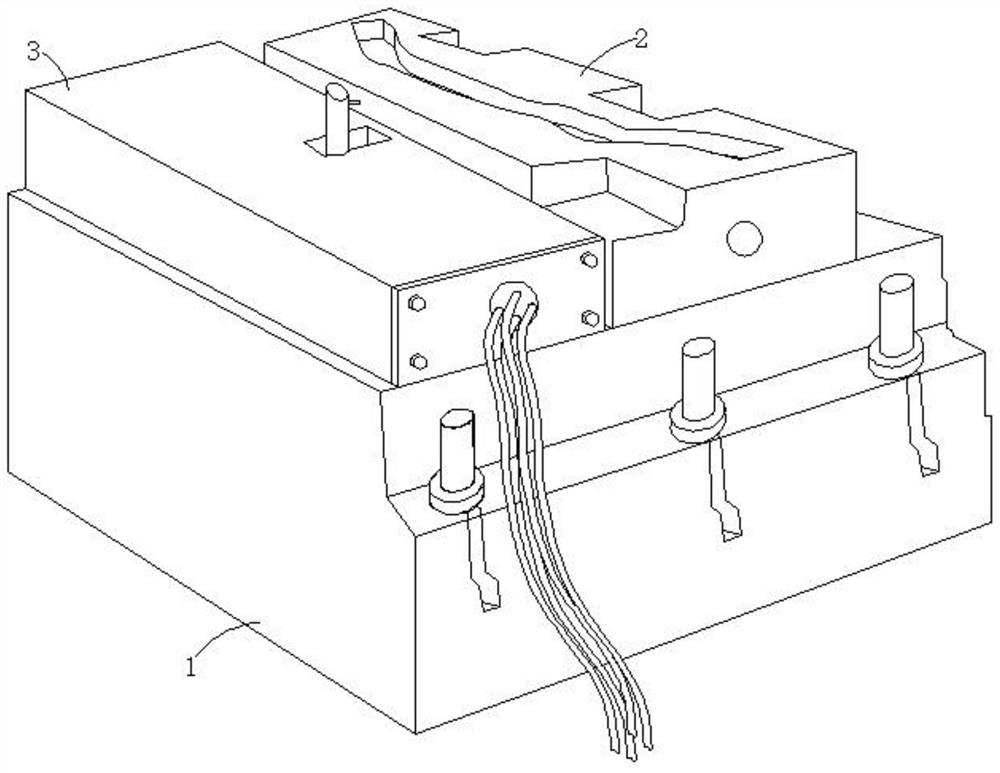

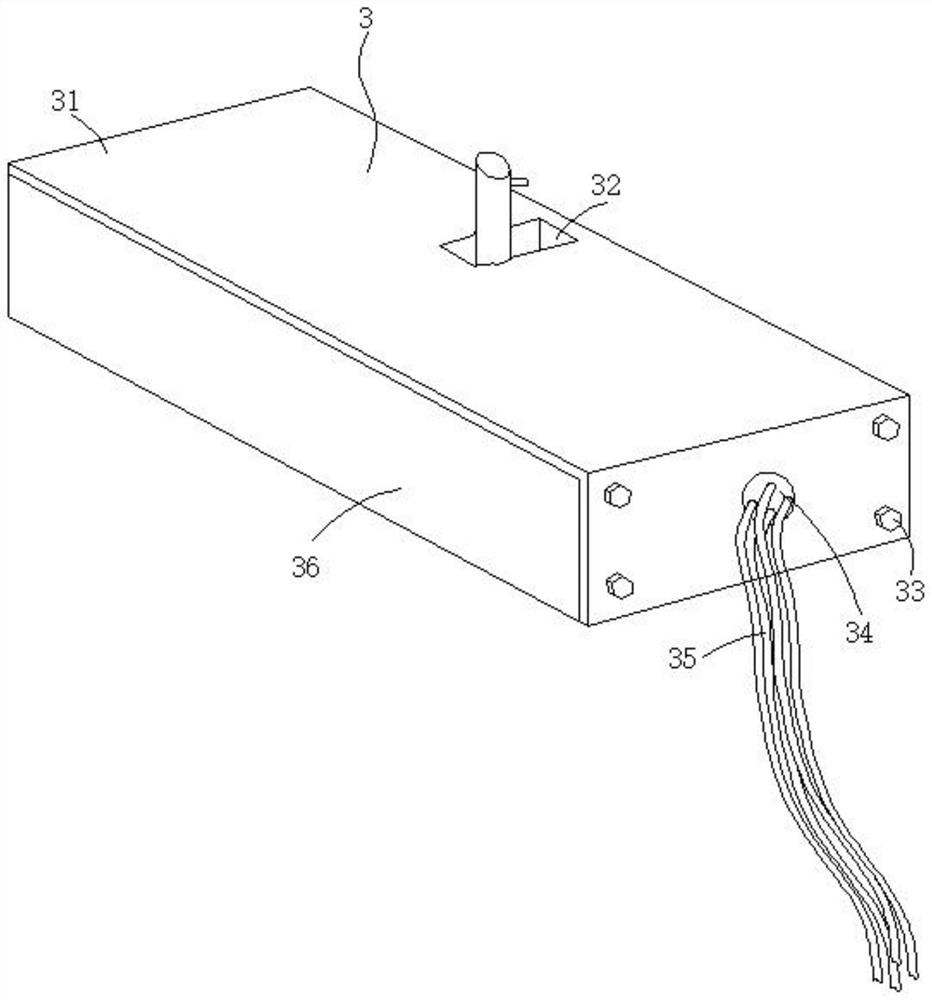

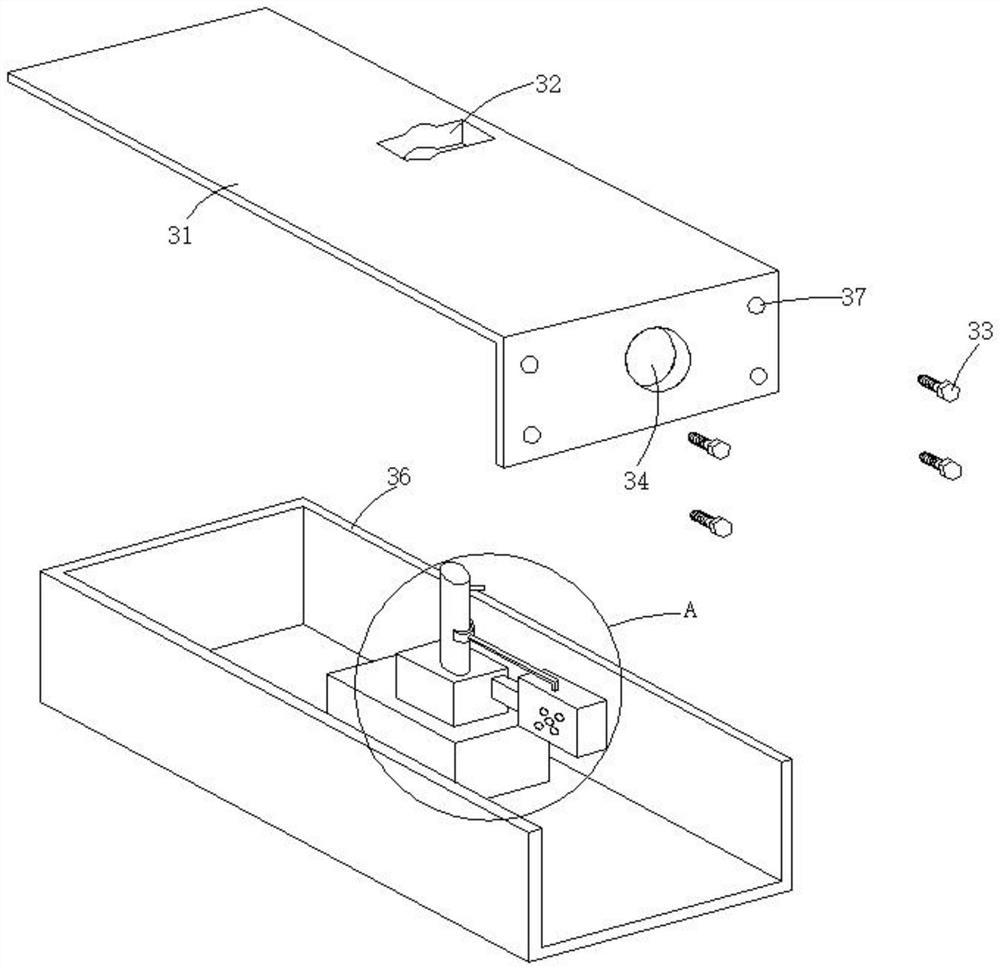

[0030] Attached below Figure 1-8 The present invention is further described with embodiment:

[0031] An adjustable graphite milk spray system for friction presses, including a base 1, a forming mold 2 and a spraying device 3, the forming mold 2 and the spraying device 3 are all arranged on the base 1, and the spraying device 3 includes a cover plate 31 and a box body 36, the upper plate of the cover plate 31 is provided with a through hole 32, and the front side plate of the cover plate 31 is provided with a mounting hole 34 and a fixing screw hole 37, and the cover plate 31 and the box body 36 pass through the fixing screw 33 The thread is fixed, and the fixing screw 33 is threaded with the fixing screw hole 37. A power mechanism 314 is arranged in the box body 36, and a spray pipe 312 is rotated on the upper end of the power mechanism 314, and the upper end side plate of the spray pipe 312 runs through A spray head 313 is provided, and a spray pipe 312 is movably inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com