Gypsum-based ceramic tile adhesive and preparation method thereof

A technology of adhesives and ceramic tiles, which is applied in the field of building materials, can solve the problems of adhesive hollowing and falling off, and achieve the effects of reducing environmental pressure, increasing waste utilization, and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

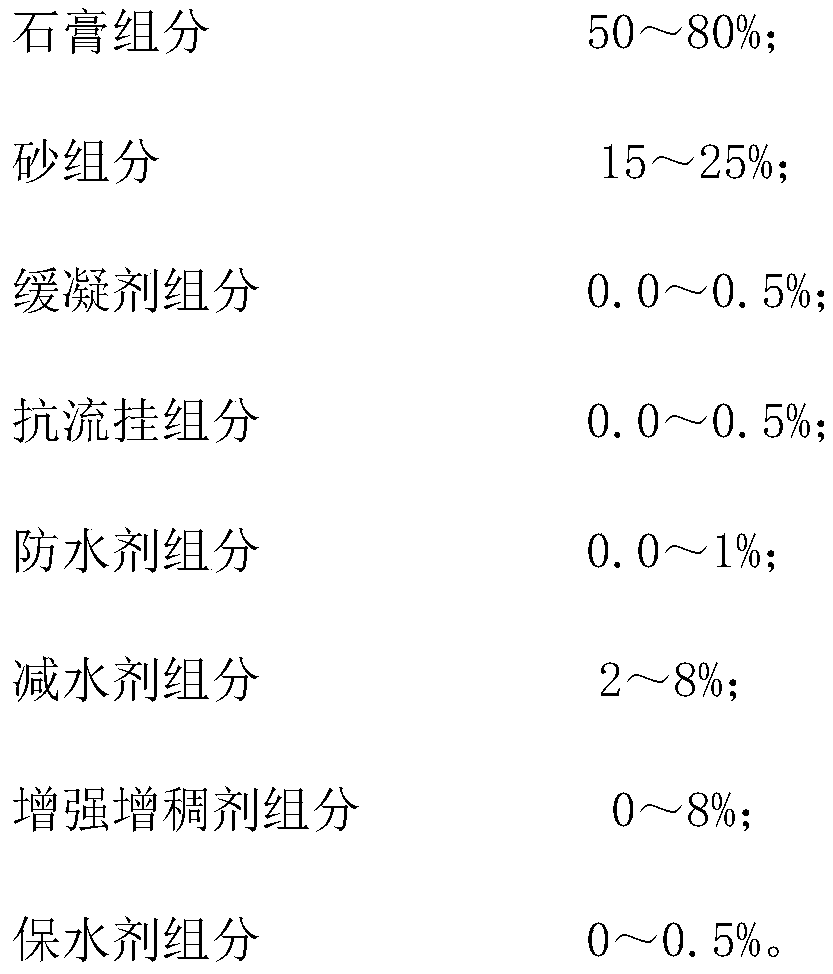

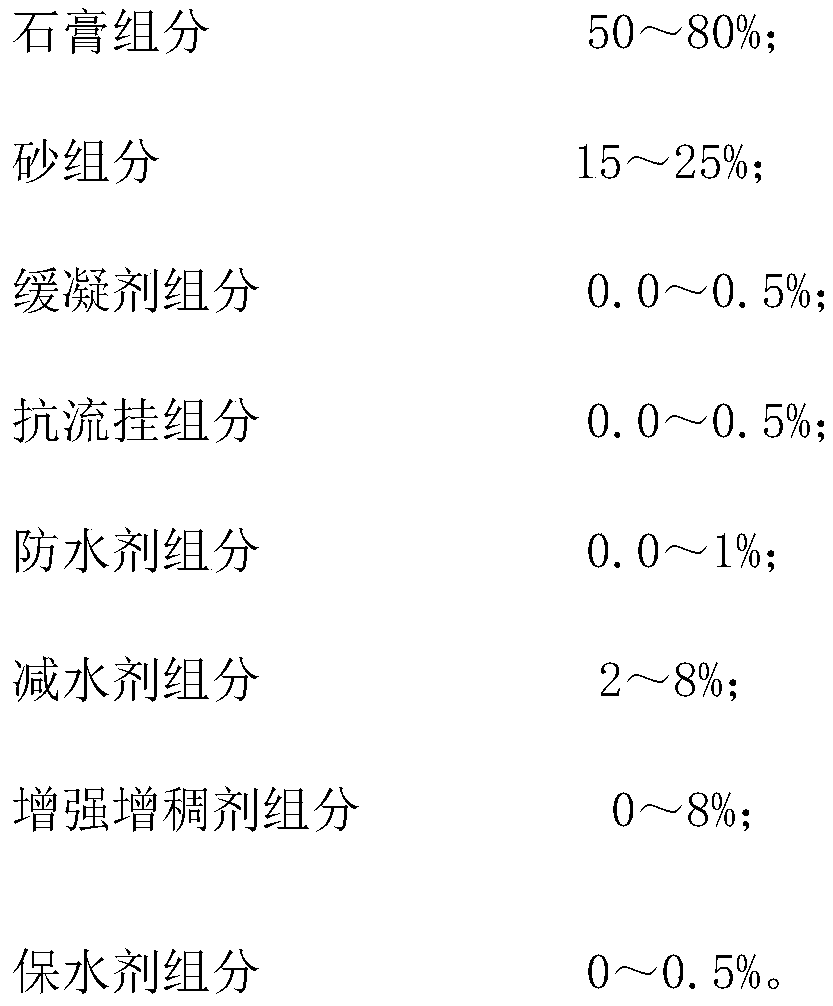

[0027] This embodiment provides a gypsum-based ceramic tile adhesive including gypsum components, sand components, retarder components, anti-sagging components, waterproofing agent components, water-reducing agent components, water-retaining agent components and enhanced thickeners Components, wherein the gypsum component uses phosphogypsum; the sand component uses 40-140 mesh sand; water-repellent; the water-reducing agent component is polycarboxylate water-reducer; the water-retaining agent component is hydroxypropyl methylcellulose ether; the thickener component is vinyl acetate-ethyl polymer, and the latex powder; the weight percentages of each component are as follows:

[0028]

Embodiment 2

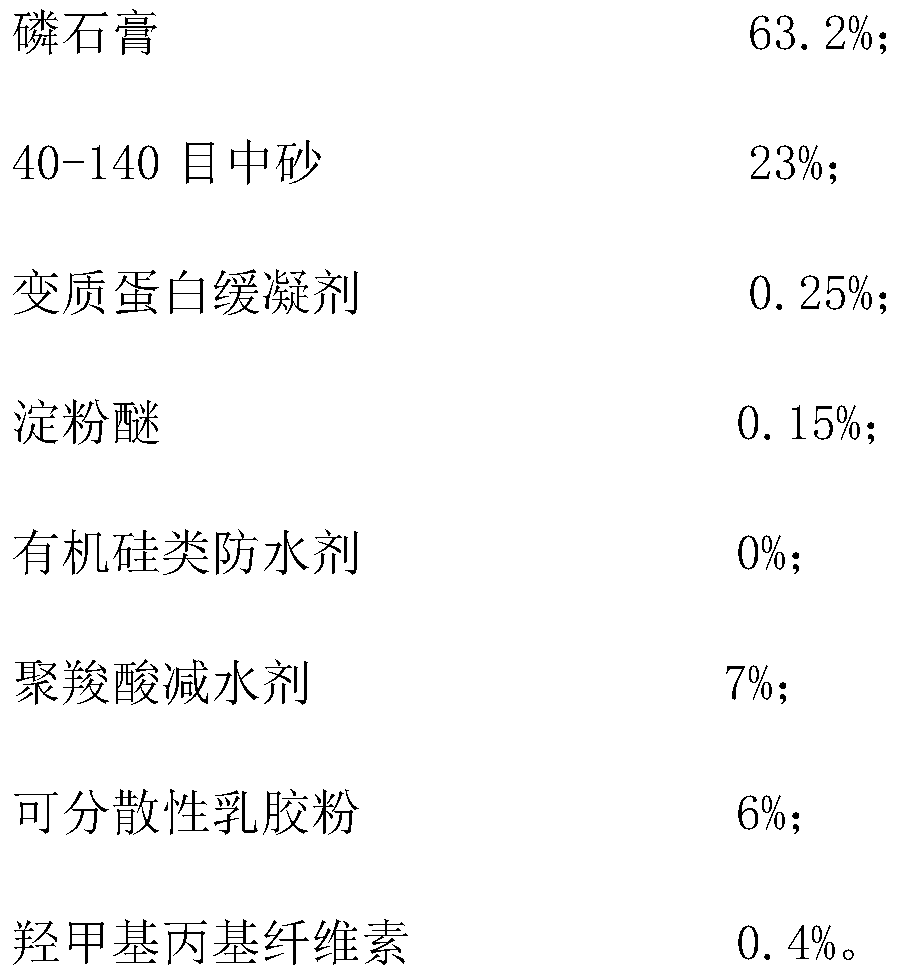

[0030] This embodiment provides a gypsum-based ceramic tile adhesive including gypsum components, sand components, retarder components, anti-sagging components, waterproofing agent components, water-reducing agent components, water-retaining agent components and enhanced thickeners Components, wherein the gypsum component uses phosphogypsum; the sand component uses 40-140 mesh sand; water-repellent; the water-reducing agent component is polycarboxylate water-reducer; the water-retaining agent component is hydroxypropyl methylcellulose ether; the thickener component is vinyl acetate-ethyl polymer, and the latex powder; the weight percentages of each component are as follows:

[0031]

Embodiment 3

[0033] This embodiment provides a gypsum-based ceramic tile adhesive including gypsum components, sand components, retarder components, anti-sagging components, waterproofing agent components, water-reducing agent components, water-retaining agent components and enhanced thickeners Components, wherein the gypsum component uses phosphogypsum; the sand component uses 40-140 mesh sand; water-repellent; the water-reducing agent component is polycarboxylate water-reducer; the water-retaining agent component is hydroxypropyl methylcellulose ether; the thickener component is vinyl acetate-ethyl polymer, and the latex powder; the weight percentages of each component are as follows:

[0034]

[0035]

[0036] The gypsum components used in Embodiment 1, Embodiment 2, and Embodiment 3 can also use other gypsum powders that meet the 3.0 grade standard for building gypsum, such as desulfurized gypsum.

[0037] The 40-140 mesh medium sand used in Embodiment 1, Embodiment 2, and Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com