Preparation method of ferrite permanent magnet material with ultrafine crystal structure

A ferrite permanent magnet and ultra-fine grain technology, applied in the field of magnetic materials, can solve the problems of ferrite material price increase, and achieve the effects of reducing material costs, saving resources, and high coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

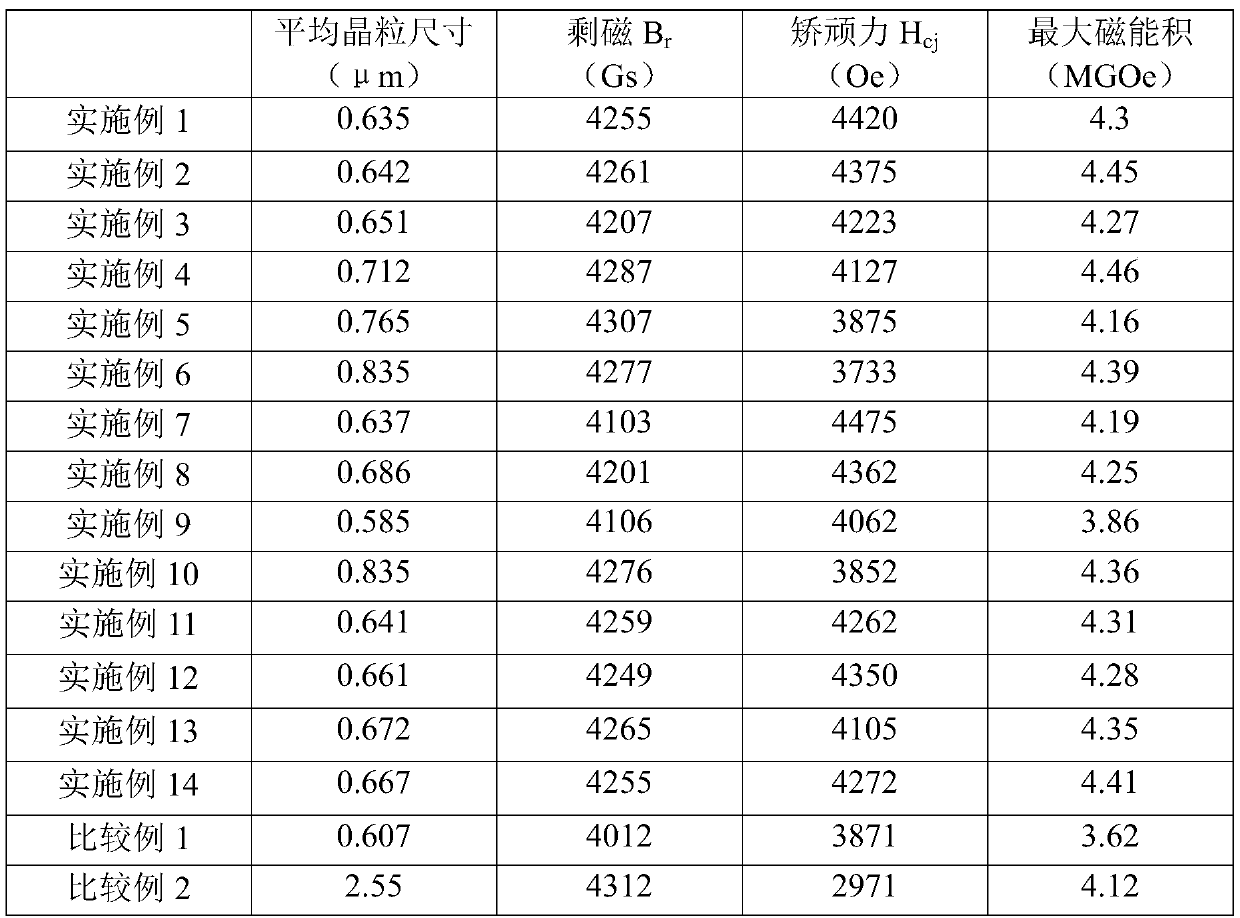

Examples

Embodiment 1

[0033] The preparation method of the ferrite permanent magnet material with ultra-fine grain structure comprises the following steps:

[0034] 1) Iron oxide and strontium carbonate are mixed through a ball mill, and the ball milling medium is deionized water, and the amount of deionized water added is 20wt% of the total amount of iron oxide and strontium carbonate, so that it is uniformly dispersed to obtain a mixture, wherein the iron element and strontium The mass ratio of elements is 12:1;

[0035] 2) After drying the mixture, crush it to obtain a dry powder, add calcium permanganate, the addition of calcium permanganate is 0.5wt% of the dry powder, and mix evenly;

[0036] 3) Pre-fired at 850°C to obtain a pre-fired material with ultra-fine grains, the grain size of the pre-fired material is 0.5 μm;

[0037] 4) Coarsely crush the calcined material to obtain a coarse powder with a particle size of 5 μm, and add the mixture Sr to the coarse powder 0.2 Zn 0.1 Na 0.3 Si 0...

Embodiment 2

[0040] The preparation method of the ferrite permanent magnet material with ultra-fine grain structure comprises the following steps:

[0041] 1) Iron oxide and strontium carbonate are mixed through a ball mill, and the ball milling medium is deionized water, and the amount of deionized water added is 20wt% of the total amount of iron oxide and strontium carbonate, so that it is uniformly dispersed to obtain a mixture, wherein the iron element and strontium The mass ratio of elements is 12:1;

[0042] 2) After drying the mixture, crush it to obtain a dry powder, add calcium permanganate, the amount of calcium permanganate added is 1wt% of the dry powder, and mix evenly;

[0043] 3) Pre-fired at 850°C to obtain a pre-fired material with ultra-fine grains, the grain size of the pre-fired material is 0.5 μm;

[0044] 4) Coarsely crush the calcined material to obtain a coarse powder with a particle size of 5 μm, and add the mixture Sr to the coarse powder 0.2 Zn 0.1 Na 0.3 Si ...

Embodiment 3

[0047] The preparation method of the ferrite permanent magnet material with ultra-fine grain structure comprises the following steps:

[0048] 1) Iron oxide and strontium carbonate are mixed through a ball mill, and the ball milling medium is deionized water, and the amount of deionized water added is 20wt% of the total amount of iron oxide and strontium carbonate, so that it is uniformly dispersed to obtain a mixture, wherein the iron element and strontium The mass ratio of elements is 12:1;

[0049] 2) After drying the mixture, crush it to obtain a dry powder, add calcium permanganate, the addition of calcium permanganate is 1.5wt% of the dry powder, and mix evenly;

[0050] 3) Pre-fired at 850°C to obtain a pre-fired material with ultra-fine grains, the grain size of the pre-fired material is 0.5 μm;

[0051] 4) Coarsely crush the calcined material to obtain a coarse powder with a particle size of 5 μm, and add the mixture Sr to the coarse powder 0.2 Zn 0.1 Na 0.3 Si 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com