A method for improving the quality of single crystal crystallization

A high-quality, single-crystal technology, applied in the field of improving the crystal quality of bromine, lead and cesium single crystals, and improving the crystal quality of single crystals, can solve the problems of low crystal quality and segregation crystal quality, and can adjust the growth rate, improve the crystal quality, and reduce the sub-crystal quality. grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

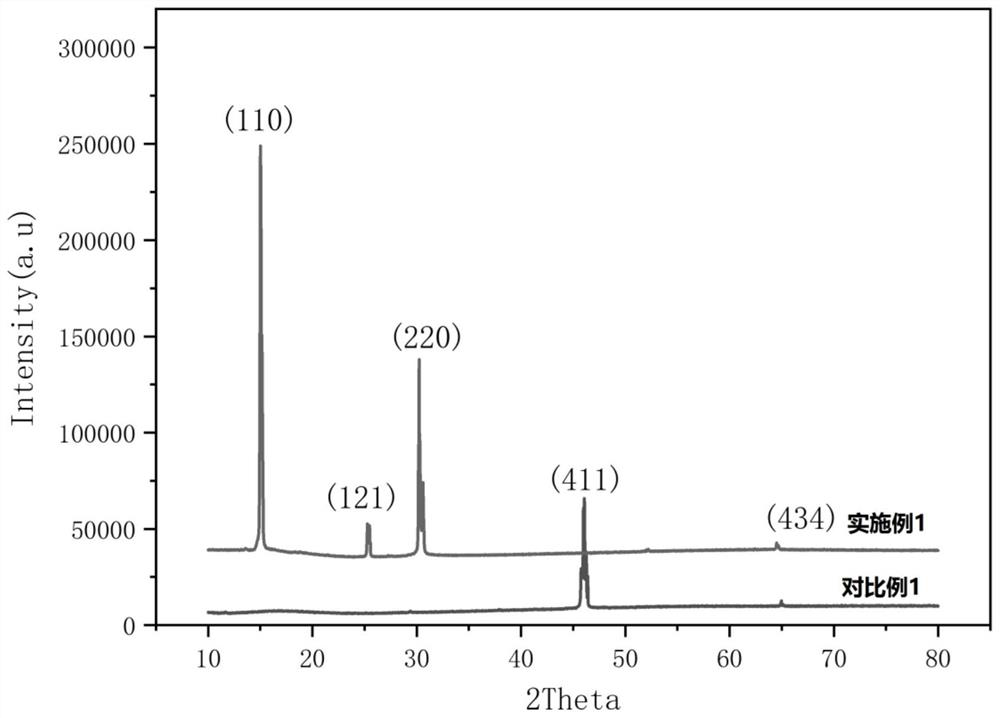

Embodiment 1

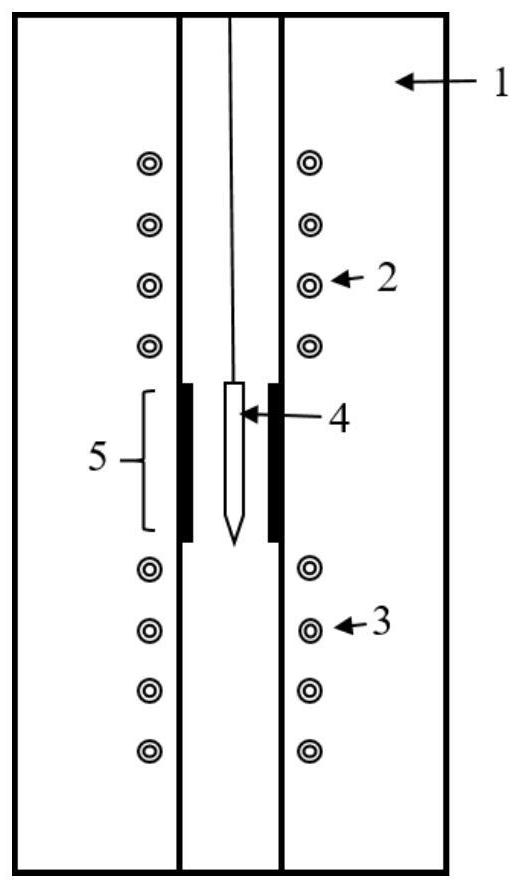

[0061] (1) placing the container containing the single crystal raw material in the growth zone of the vertical growth furnace;

[0062] (2) The upper part of the growth zone is provided with a first heating temperature zone, and the lower part of the growth zone is provided with a second heating temperature zone; the temperature program of the growth furnace is set, which is divided into three stages, the first stage, the upper temperature zone target The temperature is set to 525°C, and the target temperature in the lower temperature zone is set to 680°C. At this time, the corresponding first temperature gradient is 13°C / cm. When the furnace temperature reaches the set temperature, keep it warm for 15 hours; in the second stage, the target temperature in the upper temperature zone is set to 680°C, and the target temperature in the lower temperature zone is set to 535°C. At this time, the corresponding second temperature gradient is 11°C / cm . When the temperature reaches the ...

Embodiment 2

[0065] (1) placing the container containing the single crystal raw material in the growth zone of the vertical growth furnace;

[0066] (2) The upper part of the growth zone is provided with a first heating temperature zone, and the lower part of the growth zone is provided with a second heating temperature zone; the temperature program of the growth furnace is set, which is divided into three stages, the first stage, the upper temperature zone target The setting is 550°C, and the target temperature in the lower temperature zone is set to 720°C. At this time, the corresponding first temperature gradient is 17°C / cm. When the furnace temperature reaches the set temperature, keep it warm for 2 hours; in the second stage, the target temperature in the upper temperature zone is set to 620°C, and the target temperature in the lower temperature zone is set to 490°C. At this time, the corresponding first temperature gradient is 5°C / cm . When the temperature reaches the set temperatur...

Embodiment 3

[0068] (1) placing the container containing the single crystal raw material in the growth zone of the vertical growth furnace;

[0069] (2) The upper part of the growth zone is provided with a first heating temperature zone, and the lower part of the growth zone is provided with a second heating temperature zone; the temperature program of the growth furnace is set, which is divided into three stages, the first stage: the upper temperature zone target The temperature is set to 480°C, and the target temperature in the lower temperature zone is set to 640°C. At this time, the corresponding first temperature gradient is 13°C / cm. When the furnace temperature reaches the set temperature, keep it warm for 10 hours; the second stage: set the temperature in the upper temperature zone to 660°C, and set the temperature in the lower temperature zone to 490°C. At this time, the corresponding first temperature gradient is 8°C / cm. When the temperature reaches the set temperature, keep it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com