Connecting structure of steel pipe column and steel beam

A technology for connecting structures and steel pipe columns, which is applied in the direction of building construction and construction, can solve the problems of increasing the relative wall thickness of steel pipe columns, achieve the effects of increasing anchorage length, avoiding welding operations, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

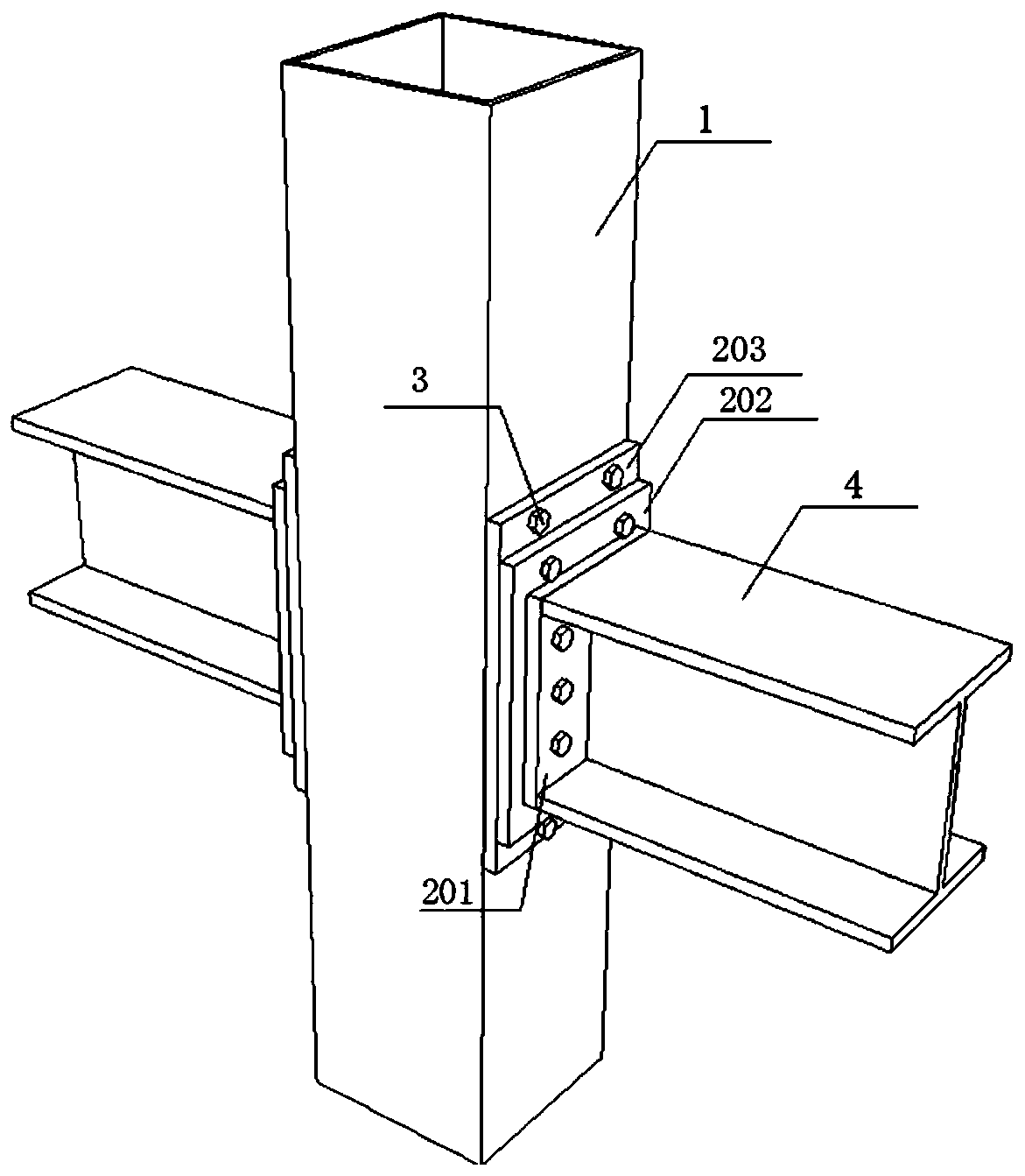

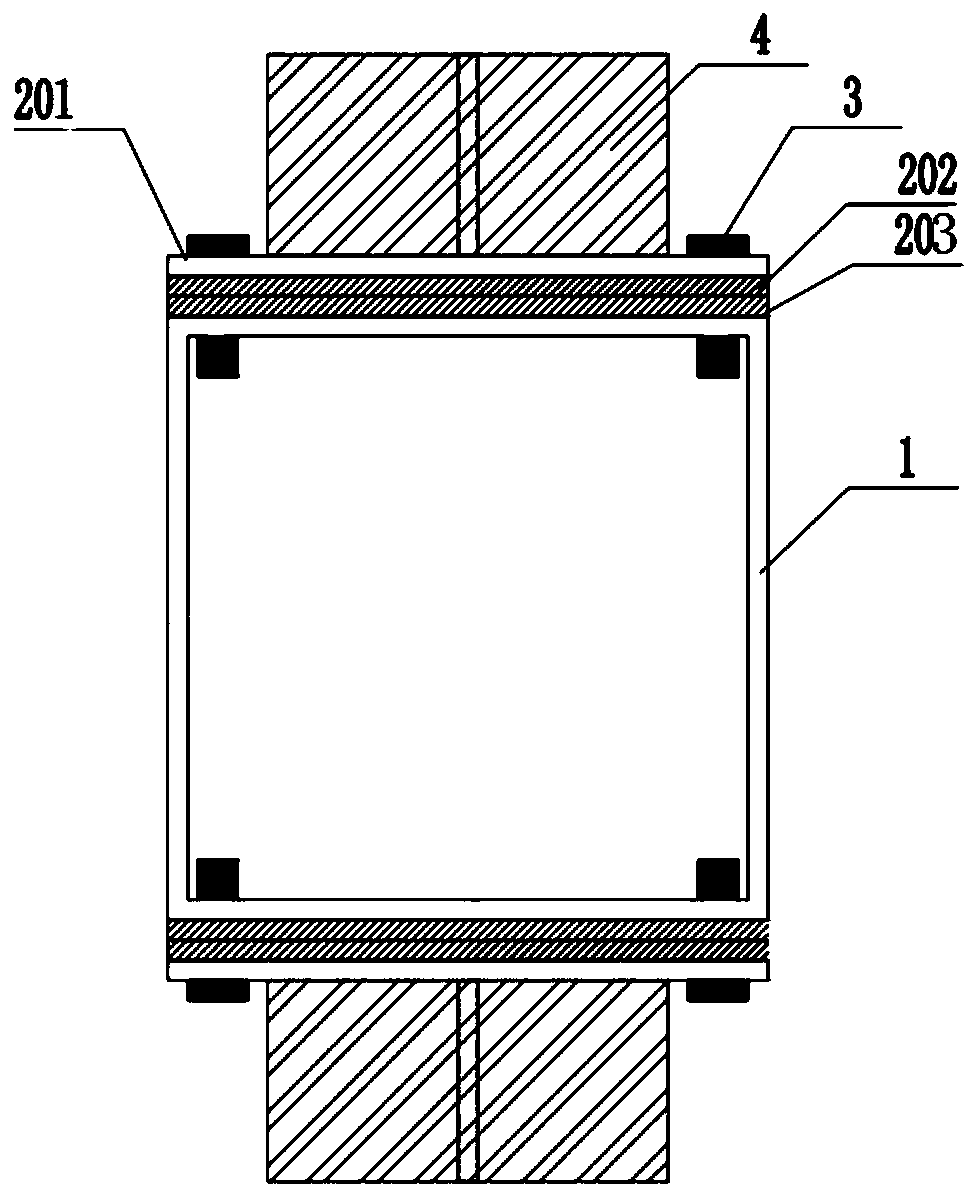

[0040] In a typical implementation of the present application, such as Figure 1-Figure 2 As shown, an auxiliary connection structure for connecting steel beams and steel pipe bodies is proposed.

[0041] A connection structure for a steel pipe column and a steel beam, including a connection member, the connection member includes at least one connection plate 202 (203 may not be included, described as existing 203 in this example), and one side of the connection member is used for laminating the steel pipe The other side of the column 1 is used to connect the end plate 201 of the steel beam 4. The end plate 201 is provided with a through hole, and the connecting plates 202 and 203 are provided with a first threaded hole, and the first threaded hole is equipped with A unilateral bolt 3, which passes through the end plate 201, connecting members 202 and 203, and the wall of the steel pipe column 1 in sequence, and the threaded part of the unilateral bolt 3 is connected with the ...

Embodiment 2

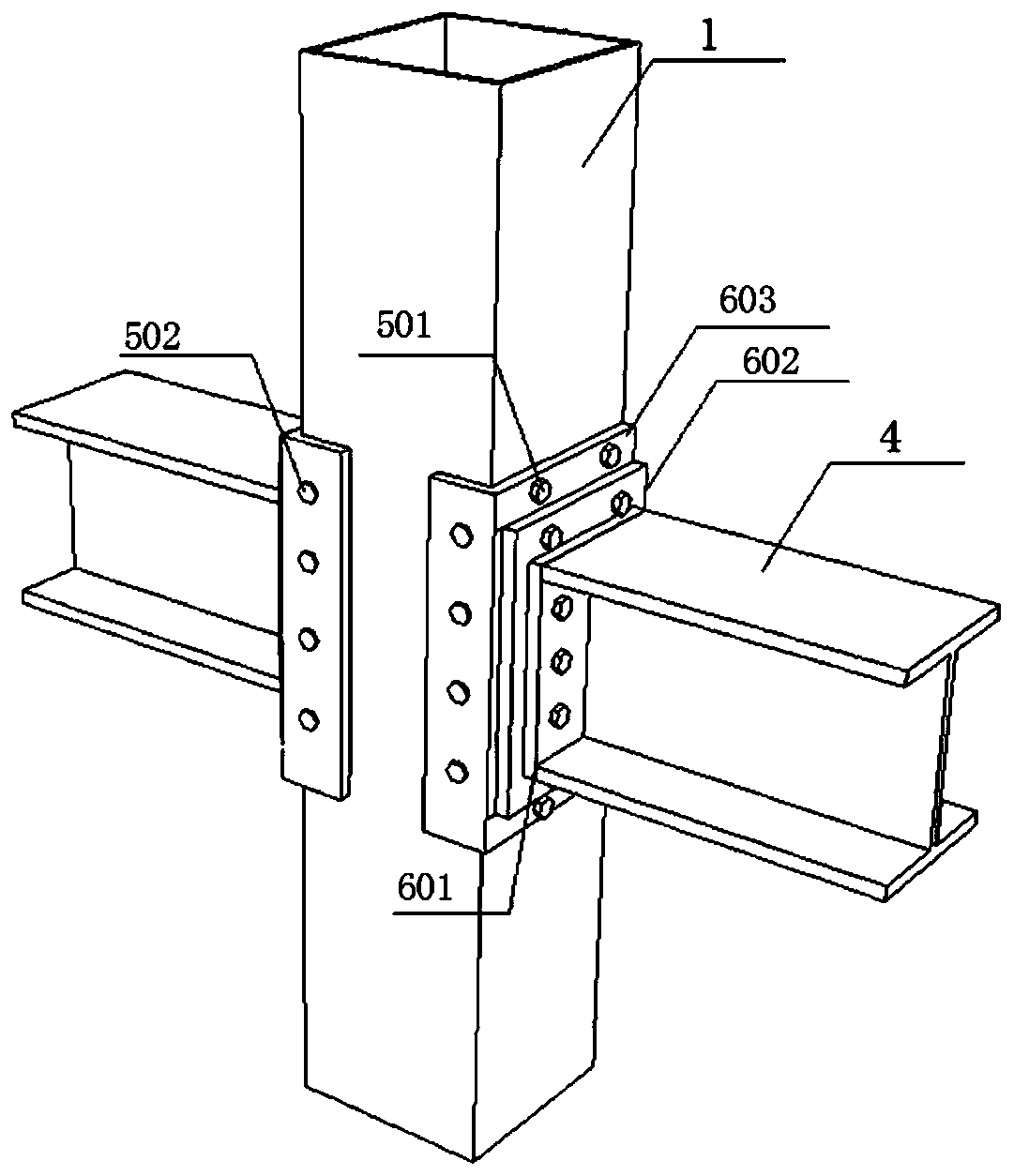

[0048] The present application also provides another connection structure between steel pipe columns and steel beams, such as Figure 3-4 As shown, it is different from the connecting member in Embodiment 1.

[0049] It includes a connecting member, the connecting member includes a first connecting plate, and the first connecting plate includes a bent plate and a superimposed plate, one side of the superimposed plate is attached to the first side of the steel pipe column, and the other side is connected to the end plate of the steel beam , the bent plate is attached to the second side adjacent to the first side of the steel pipe column, the first connecting plate is provided with a first threaded hole, and the first threaded hole is matched with a first unilateral bolt and The second unilateral bolt is provided with a through hole on the end plate of the steel beam, and the first unilateral bolt passes through the through hole and the first threaded hole on the superimposed pl...

Embodiment 3

[0058] The present application also provides a third connection structure between a steel pipe column and a steel beam, the difference from Embodiment 2 lies in the first connection plate;

[0059] In this embodiment, the connecting member includes two first connecting plates 802. The first connecting plate includes a bent plate and a superimposed plate. The end plate of the beam, the bent plate is used to fit the second side adjacent to the first side of the steel pipe column, a gap is provided between the two first connecting plates, and the gap is used as an axis-symmetric arrangement;

[0060] The first connecting plate is a bent structure, including a bent plate and a superimposed plate connected to each other, the bent plate is perpendicular to the superimposed plate, and the two bent plates corresponding to the two first connecting plates are used for A pair of second sides of the steel pipe column are attached respectively; the steel beam end plate 801 is between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com