Selective catalytic reduction (SCR) system of vehicle and backflow flow measuring module and measuring method thereof

A technology of SCR system and return flow, applied in the field of vehicle SCR system, can solve problems such as cost increase, difficulty in calibration and adjustment, and impact of SCR system related functions, and achieve the effect of avoiding cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present application are described below with reference to the accompanying drawings.

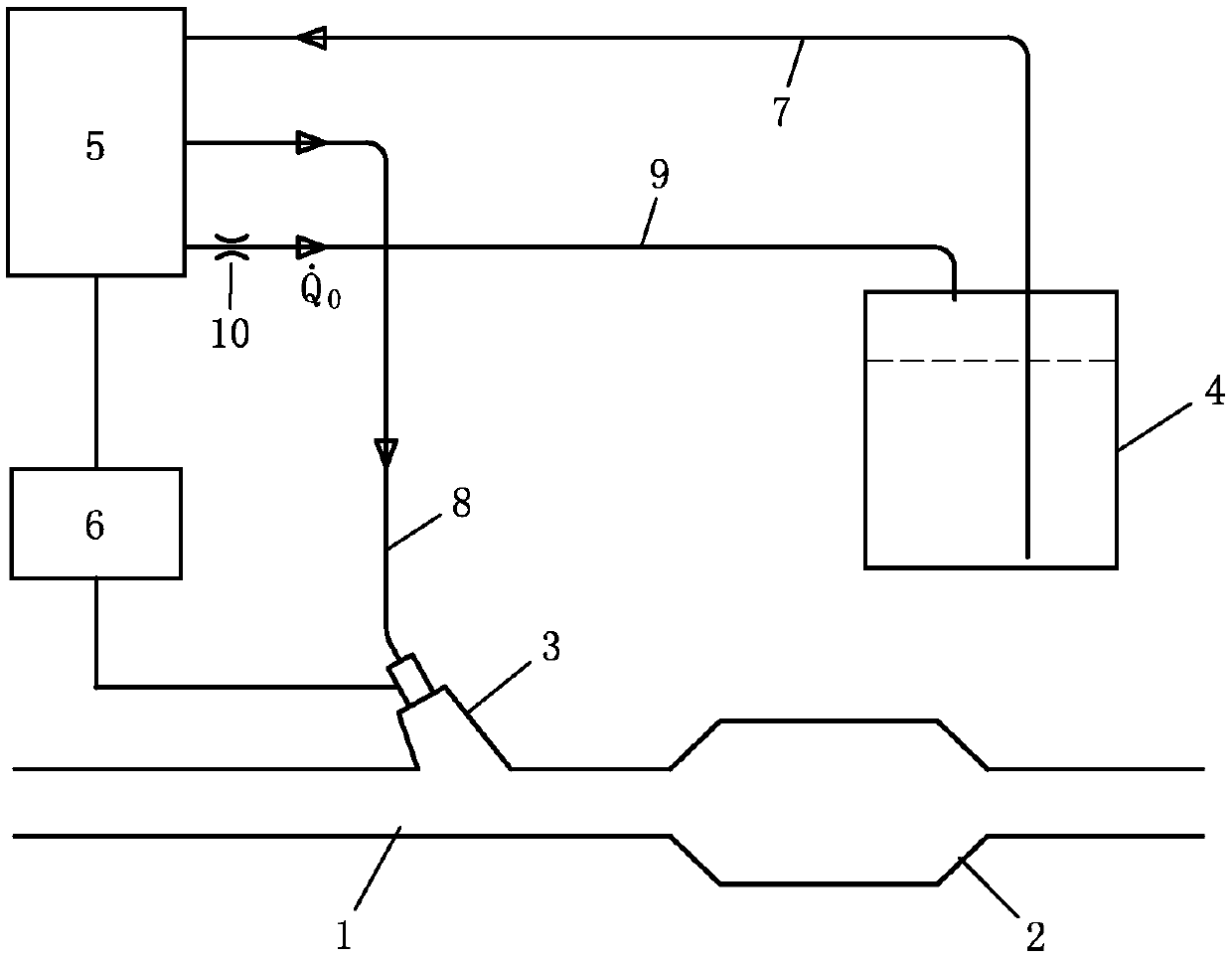

[0015] figure 1 Shown is an exhaust SCR system for a vehicle, especially a diesel engine vehicle, associated with an exhaust pipe 1 of a vehicle engine for reducing NOx in exhaust gas according to an embodiment of the present application. The SCR system includes an SCR catalyst 2 and an injection unit 3 arranged in an exhaust pipe 1 . The injection unit 3 is located upstream of the SCR catalytic converter 2, and is used to inject the exhaust gas treatment liquid (such as urea solution) from the liquid tank 4 into the exhaust gas flow in a metered manner, so that the exhaust gas and the exhaust gas treatment liquid are mixed and discharged in the SCR catalytic converter 2. A catalytic reduction reaction occurs to convert NOx to nitrogen and water.

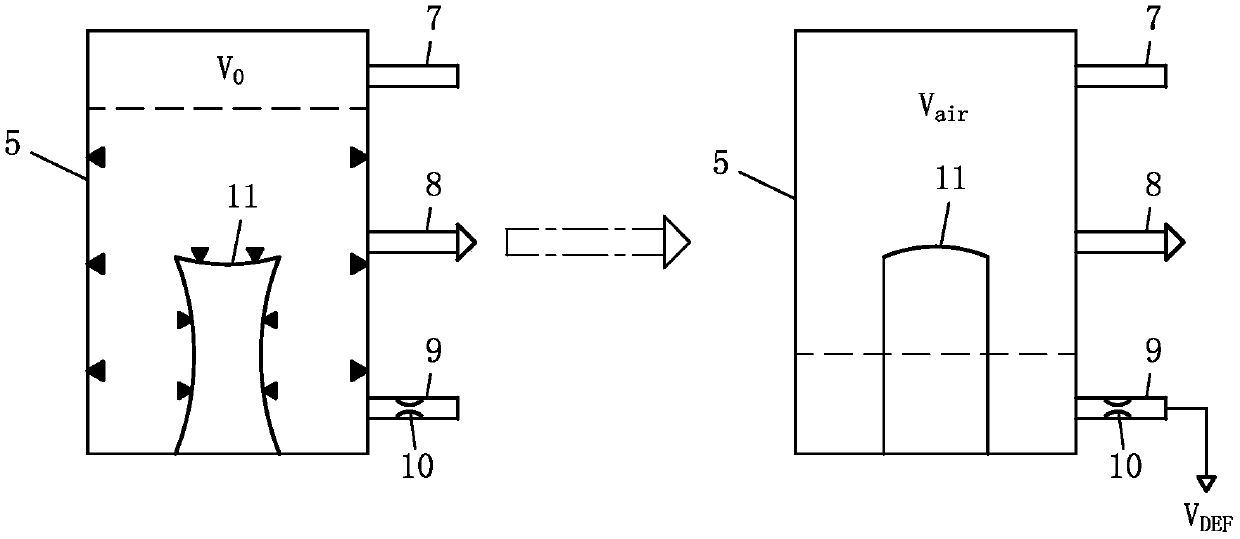

[0016] The supply unit 5 is used to supply the exhaust gas treatment liquid in the liquid tank 4 to the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com