Nitrogen-oxygen sensor ceramic core

A technology of nitrogen and oxygen sensor and ceramic core, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of polluting the measuring electrode, reducing the performance of the measuring electrode, increasing the current of the secondary pump electrode pump, etc., and simplifying the preparation process , Ease of large-scale production, and the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

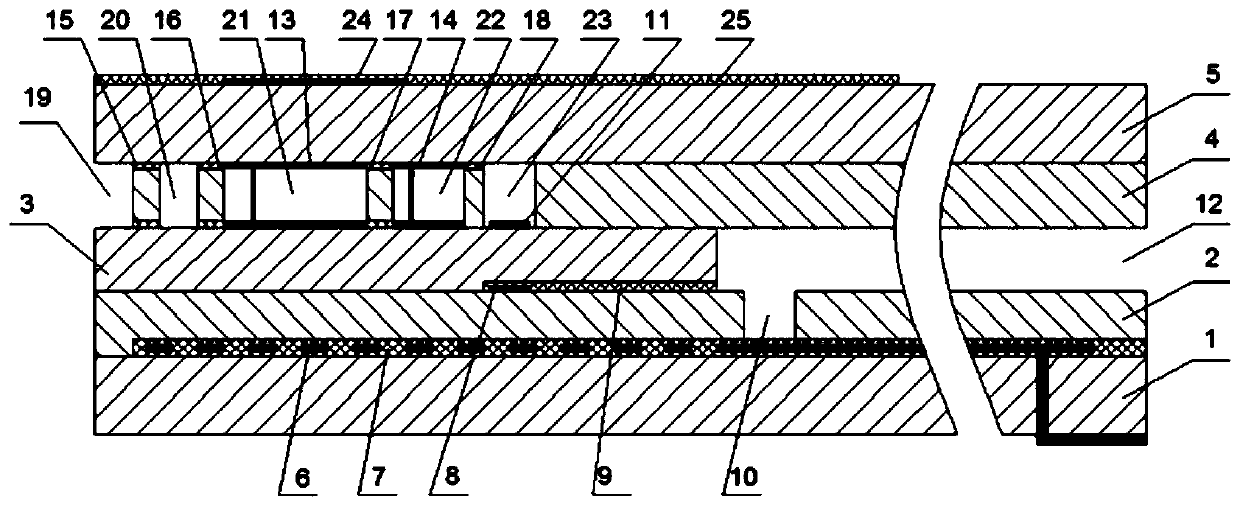

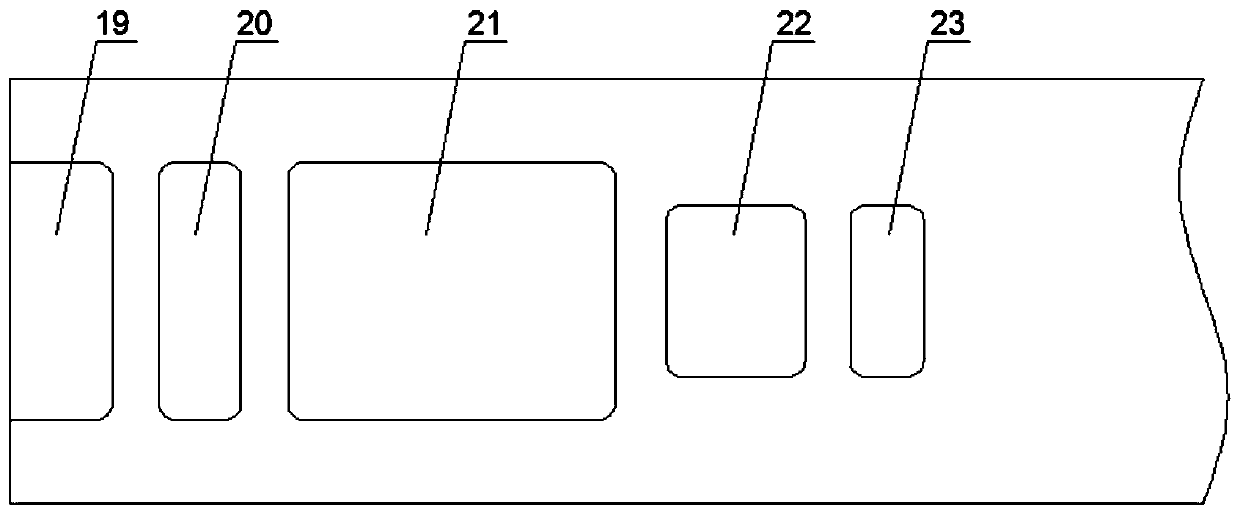

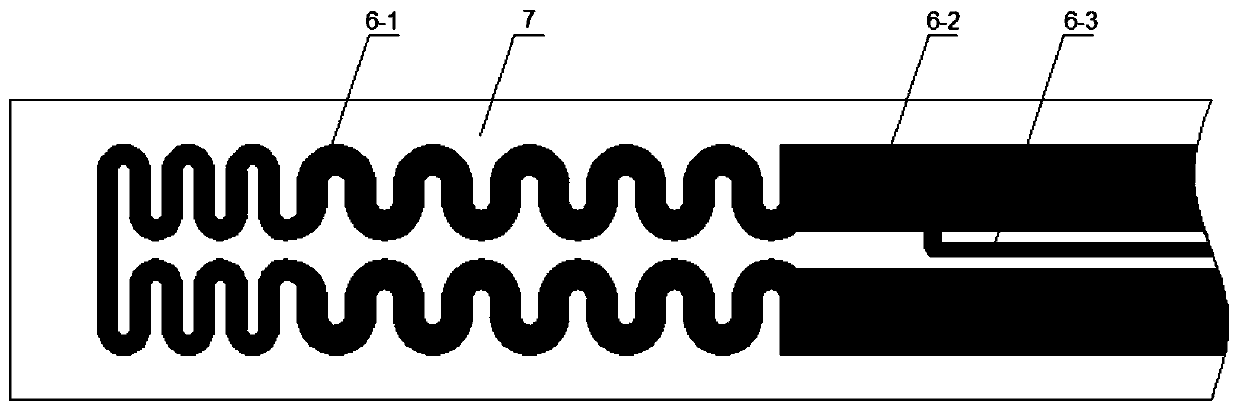

[0026] like Figure 1-Figure 3 As shown, the nitrogen and oxygen sensor ceramic core of the present invention includes: the first substrate 1 is pre-laminated to 480um, the second substrate 2, the third substrate 3, the fourth substrate 4 and the fifth substrate 5 are pre-laminated Pressed into 240um.

[0027] The second substrate adopts punching to punch out the pressure relief hole 10, the third substrate adopts punching to punch out the reference gas passage 12, and the fourth substrate adopts punching to punch out the first cavity 19, the second cavity 20, the second cavity Three cavities 21 , fourth cavities 22 and fifth cavities 23 . The secondary pump electrode 14 and the measuring electrode 11 are located in different chambers, which can prevent the pollution of the measuring electrode 11 caused by the volatilization of gold in the secondary pump electrode 14 during the sintering process, and the measuring electrode 11 decomposes the O produced by NO. 2 It is difficu...

Embodiment 2

[0038] like Figure 1-Figure 3 As shown, the nitrogen and oxygen sensor ceramic core body of the present invention includes: the first substrate 1 is pre-laminated to 500um, the second substrate 2, the third substrate 3, the fourth substrate 4 and the fifth substrate 5 are pre-laminated Pressed into 250um.

[0039] The second substrate adopts punching to punch out the pressure relief hole 10, the third substrate adopts punching to punch out the reference gas passage 12, and the fourth substrate adopts punching to punch out the first cavity 19, the second cavity 20, the second cavity Three cavities 21 , fourth cavities 22 and fifth cavities 23 . The secondary pump electrode 14 and the measuring electrode 11 are located in different chambers, which can prevent the pollution of the measuring electrode 11 caused by the volatilization of gold in the secondary pump electrode 14 during the sintering process, and the measuring electrode 11 decomposes the O produced by NO. 2 It is di...

Embodiment 3

[0047] like Figure 1-Figure 3 As shown, the nitrogen and oxygen sensor ceramic core body of the present invention includes: the first substrate 1 is pre-laminated to 520um, the second substrate 2, the third substrate 3, the fourth substrate 4 and the fifth substrate 5 are pre-laminated Pressed into 260um.

[0048] The second substrate adopts punching to punch out the pressure relief hole 10, the third substrate adopts punching to punch out the reference gas passage 12, and the fourth substrate adopts punching to punch out the first cavity 19, the second cavity 20, the second cavity Three cavities 21 , fourth cavities 22 and fifth cavities 23 . The secondary pump electrode 14 and the measuring electrode 11 are located in different chambers, which can prevent the pollution of the measuring electrode 11 caused by the volatilization of gold in the secondary pump electrode 14 during the sintering process, and the measuring electrode 11 decomposes the O produced by NO. 2 It is di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com