Characterization method for conductivity regulation in ferroelectric nano dot array

A technology of nano-dot array and conductivity, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of good ferroelectricity and large polarization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

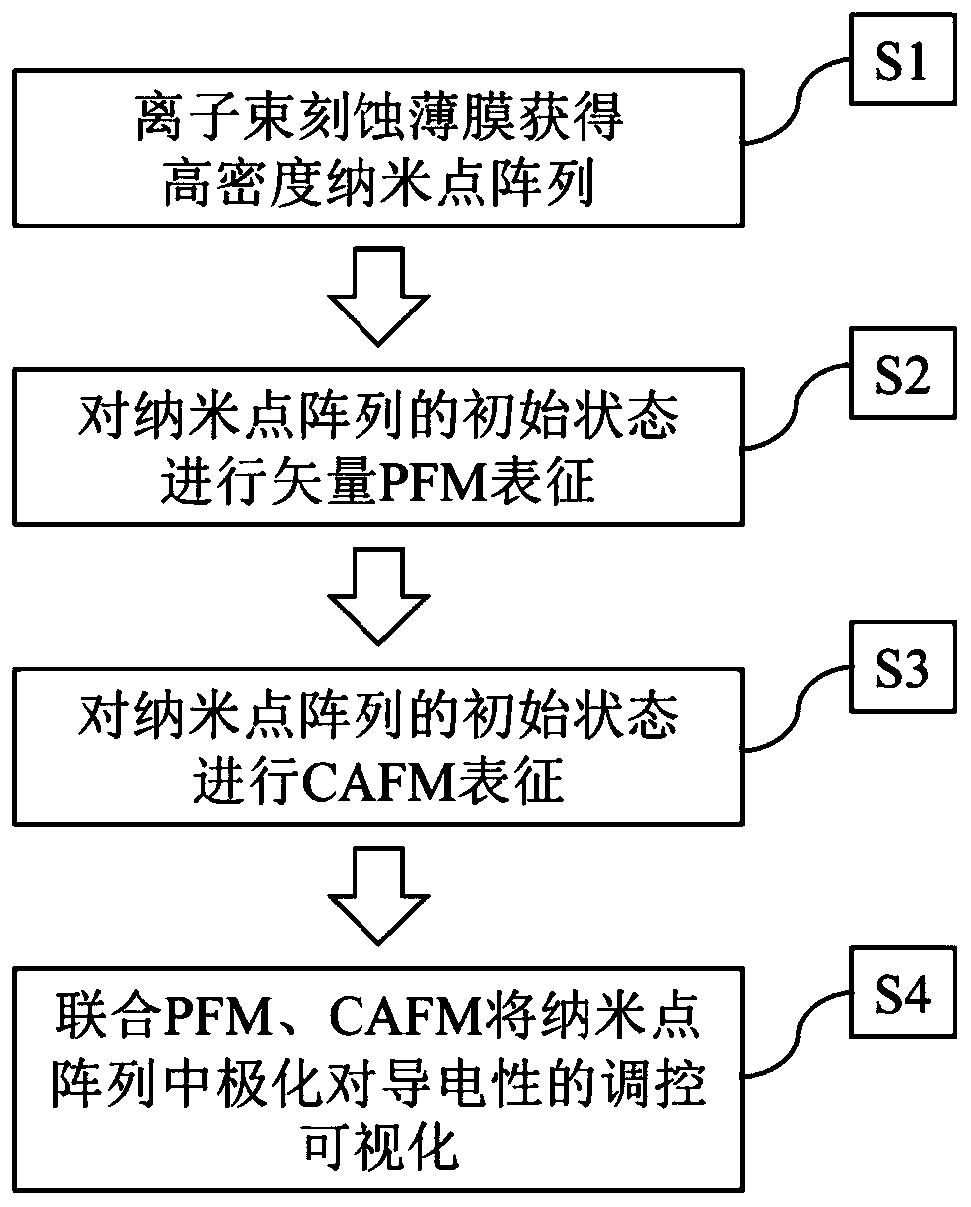

[0038] Such as Figure 1-6 as shown, figure 1 It is a schematic flowchart of a characterization method for conductivity regulation in a ferroelectric nano-dot array of the present invention. Combine below Figure 2-6 , and describe this embodiment in detail.

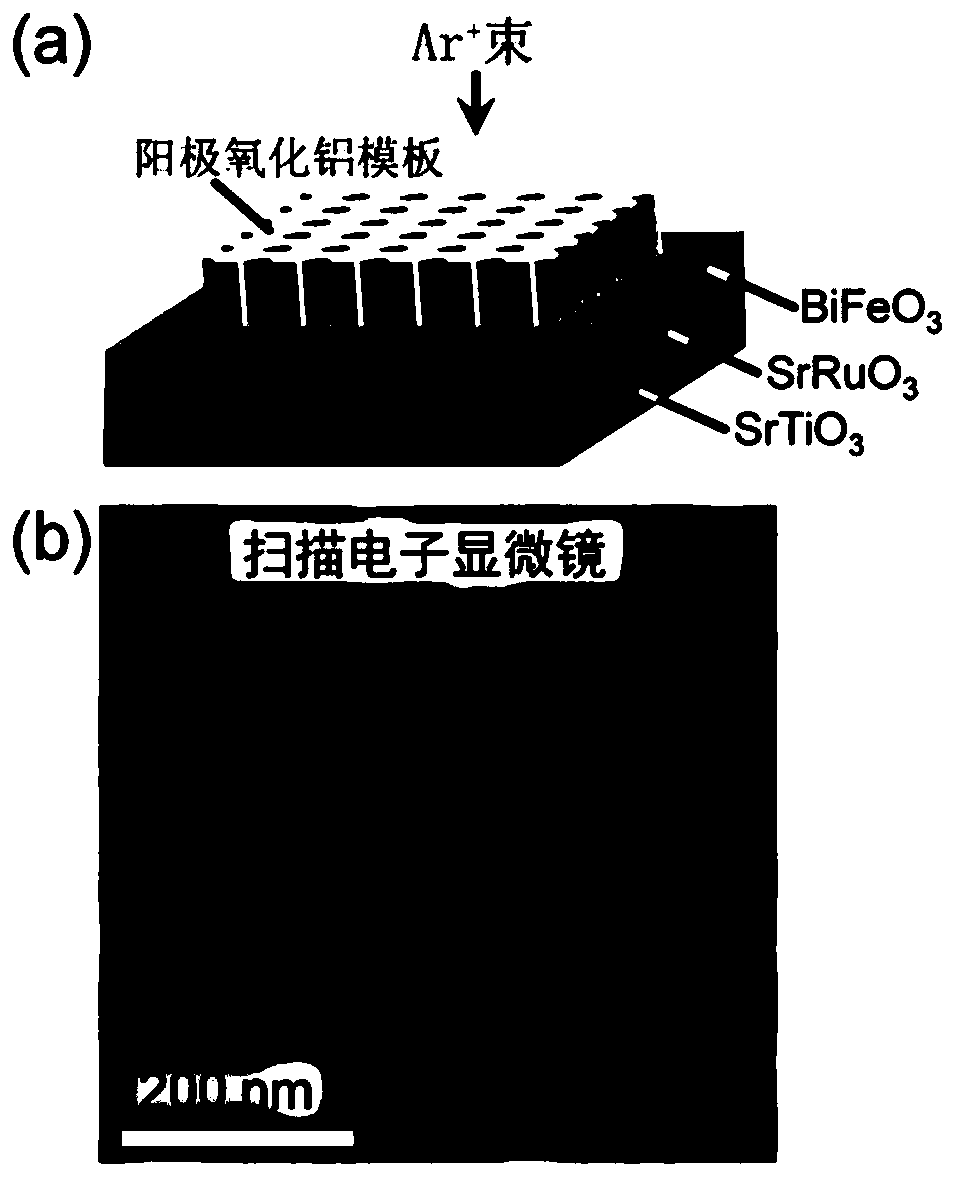

[0039] (1) According to S1, please refer to the process flow of sample preparation figure 2 .

[0040] Pre-prepared high-quality strontium titanate (SrTiO 3 ) / Strontium ruthenate (SrRuO 3 ) / BFO epitaxial film is covered with AAO template, and the film is etched by IBE method to obtain a high-density BFO ferroelectric nano-dot array sample. The SEM image shows its morphology, and the diameter of a single nano-dot is 60nm.

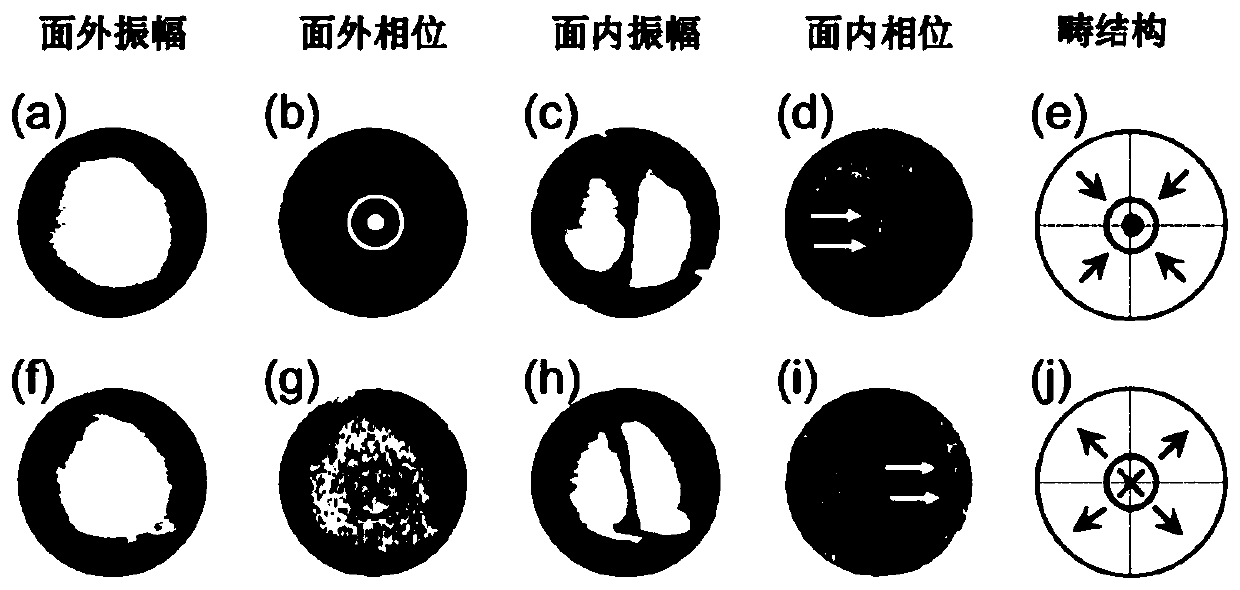

[0041] (2) According to S2, determine the domain structure of ferroelectric nanodots using the vector PFM method, see image 3 .

[0042] image 3 Two typical topological domain structures obtained for vector PFM characterization of nanodots: The first nanodot is image 3 (a-e), the second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com