a calculation co 2 Numerical simulation method of flooding minimum miscibility pressure

A miscible pressure and numerical simulation technology, applied in design optimization/simulation, earthwork drilling and production, wellbore/well components, etc., can solve problems such as long measurement time, large influence of simulation results, high technical requirements, and achieve time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) Establish a long thin tube model

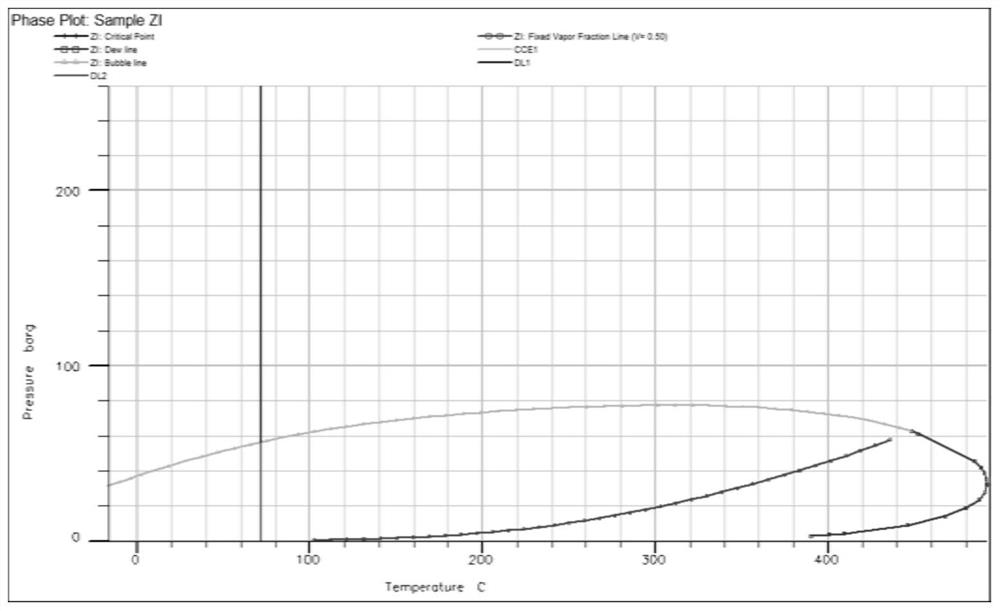

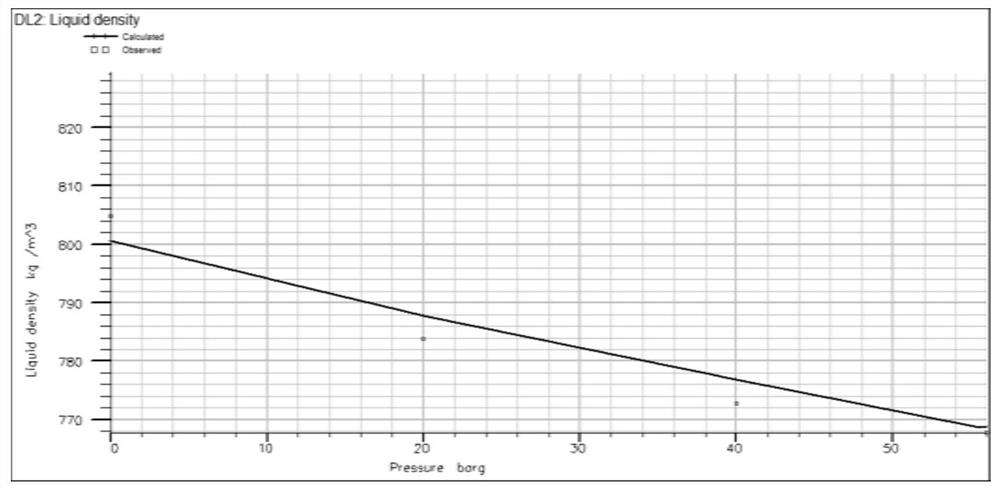

[0056] The one-dimensional thin tube model established this time is a miscible component model containing oil and water two phases, see figure 1 , figure 1 It is the long thin tube model diagram of the establishment of the present invention, the grid scale is 400 × 1 × 1, each grid is 5 cm long in the X direction, 0.4 cm long in the Y direction and Z direction, and the permeability in the X, Y, and Z directions Both are 5000mD, the porosity is 20%, the reservoir temperature is 71.6°C, the rock compressibility coefficient is 0.00002, the original oil saturation is 1, the original water saturation is 0, the original gas saturation is 0, and the oil-gas phase permeability curve for the experimental data.

[0057] In terms of well definition, an injection well (I1) is defined at the grid (1,1,1), the grid (1,1,1) is opened, the conductivity coefficient is 3000, the injection medium is defined as gas, and the injection rate is 1cm 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com