Double-tank reversed-electrode electrodialysis water purification system and table-board type water purifier thereof

A technology of inverted electrode electrodialysis and water purification system, which is applied in the field of double-box inverted electrode electrodialysis water purification system and table-top water purifiers, can solve the problem of increased risk, inability to filter and utilize concentrated water, and deterioration of water quality. and other problems to achieve the effect of reducing macromolecular substances, reducing the risk of scaling, and improving the stability of purified water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

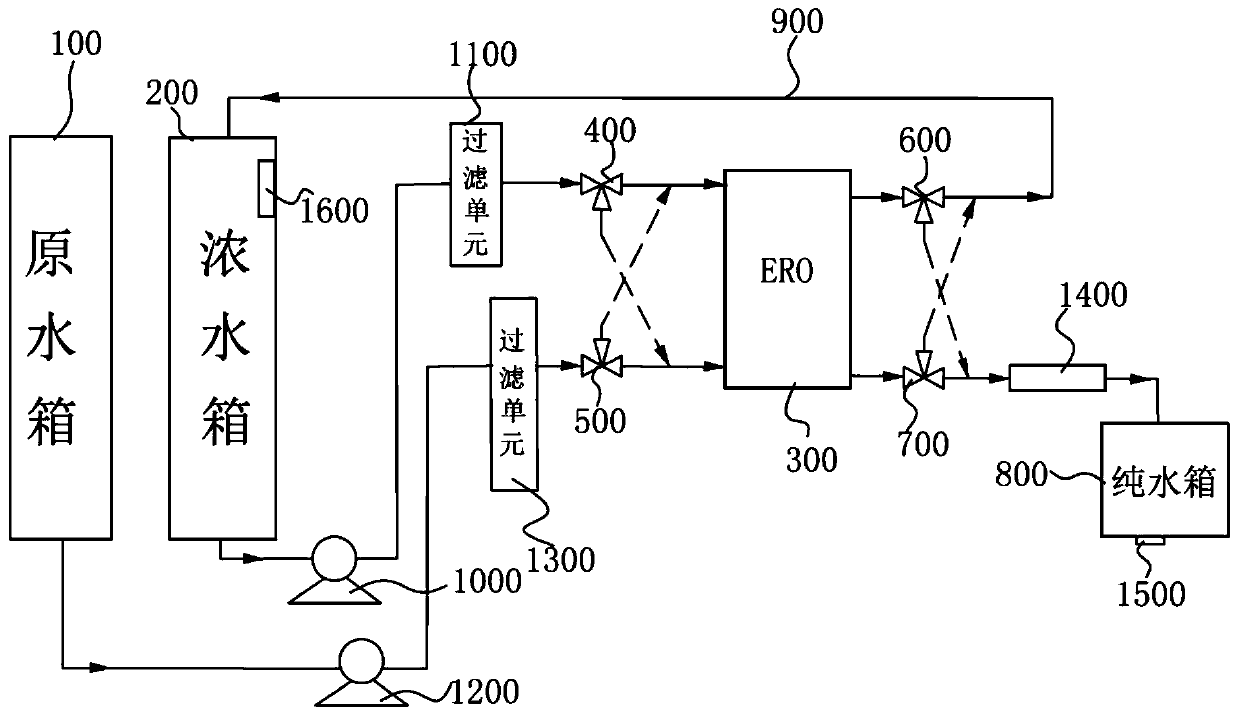

[0065] A double-box inverted electrodialysis water purification system, such as figure 1 As shown, a raw water tank 100 , a concentrated water tank, an EDR unit 300 with interchangeable electrodes, a first solenoid valve 400 , a second solenoid valve 500 , a third solenoid valve 600 and a fourth solenoid valve 700 are provided.

[0066] It should be noted that the EDR (electro-dialysis, electro-dialysis reversal) unit has a filter membrane stack structure, and uses electrodialysis technology to treat the incoming water. The purified water is discharged as pure water, and the concentrated water is discharged as concentrated water. The structure and principle of the EDR unit 300300 are common knowledge in the field, and will not be repeated here.

[0067] In this embodiment, the EDR unit 300 is provided with a first water inlet, a second water inlet, a first water outlet and a second water outlet, and the raw water tank 100 communicates with the second water inlet of the EDR uni...

Embodiment 2

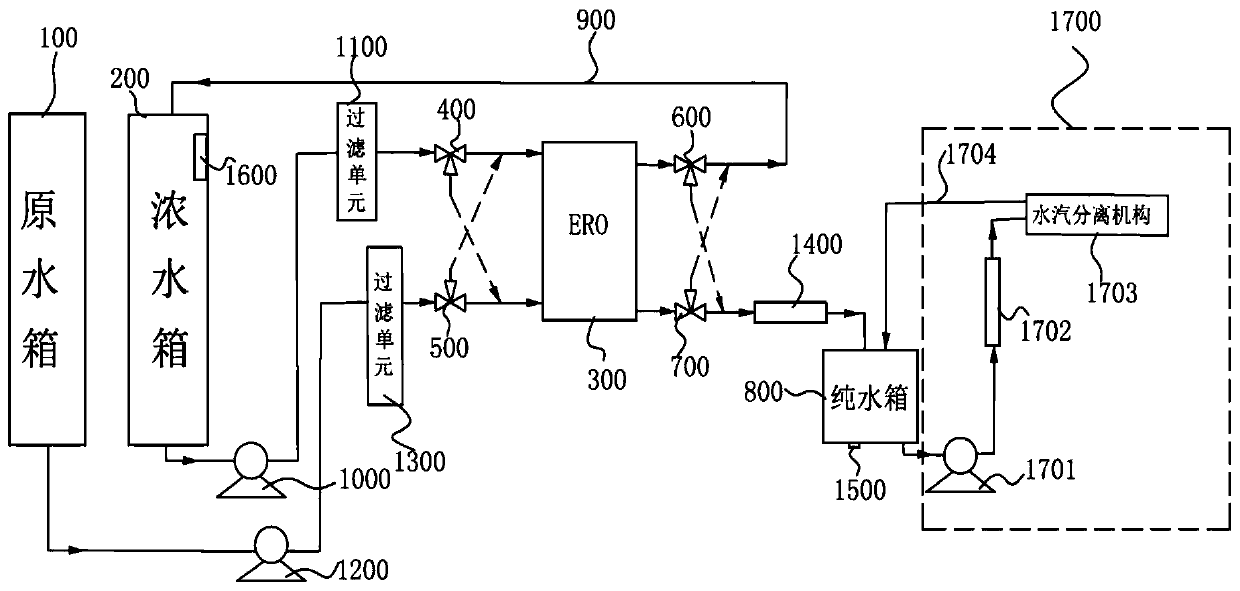

[0089] A double-box inverted electrodialysis water purification system, such as figure 2 As shown, the other structures are the same as in Embodiment 1, except that the water purification system in this embodiment is also provided with a pure water treatment unit 1700 , and the pure water treatment unit 1700 is connected to the pure water tank 800 through pipelines. The pure water treatment unit 1700 can perform disinfection and sterilization treatment on the pure water generated by the EDR unit 300 again to ensure the quality of the pure water.

[0090] In this embodiment, the pure water treatment unit 1700 is provided with a pure water self-priming mechanism 1701, a heating mechanism 1702, a water vapor separation mechanism 1703 and an overflow pipe 1704, the water inlet of the pure water self-priming mechanism 1701 and the pipeline of the pure water tank 800 Connected, the water outlet of the pure water self-priming mechanism 1701 is connected with the water inlet pipeline...

Embodiment 3

[0093] A countertop water purifier, the water purification system is provided with a raw water tank, a concentrated water tank, an EDR unit with reversible electrodes, a first solenoid valve, a second solenoid valve, a third solenoid valve and a fourth solenoid valve.

[0094] In this embodiment, the EDR unit is provided with a first water inlet, a second water inlet, a first water outlet and a second water outlet, the raw water tank communicates with the second water inlet of the EDR unit through a second solenoid valve, and the concentrated water tank communicates with the second water inlet of the EDR unit through a second solenoid valve. A solenoid valve communicates with the first water inlet, the first water outlet communicates with the concentrated water pipeline through the third solenoid valve, and the second water outlet communicates with the pure water pipeline through the fourth solenoid valve.

[0095] In this embodiment, the first solenoid valve, the second soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com