Strong brine treatment system

A treatment system and concentrated brine technology, which is applied in the field of coal chemical concentrated brine treatment, can solve problems such as high salt content, affecting the purification effect of biological treatment systems, and high density of high-salt wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0020] A concentrated brine treatment system, which is used for the treatment of concentrated brine in coal chemical industry, includes an integrated desalination device 1 and a disinfection device connected in sequence. The disinfection device can be disinfected with sodium hypochlorite.

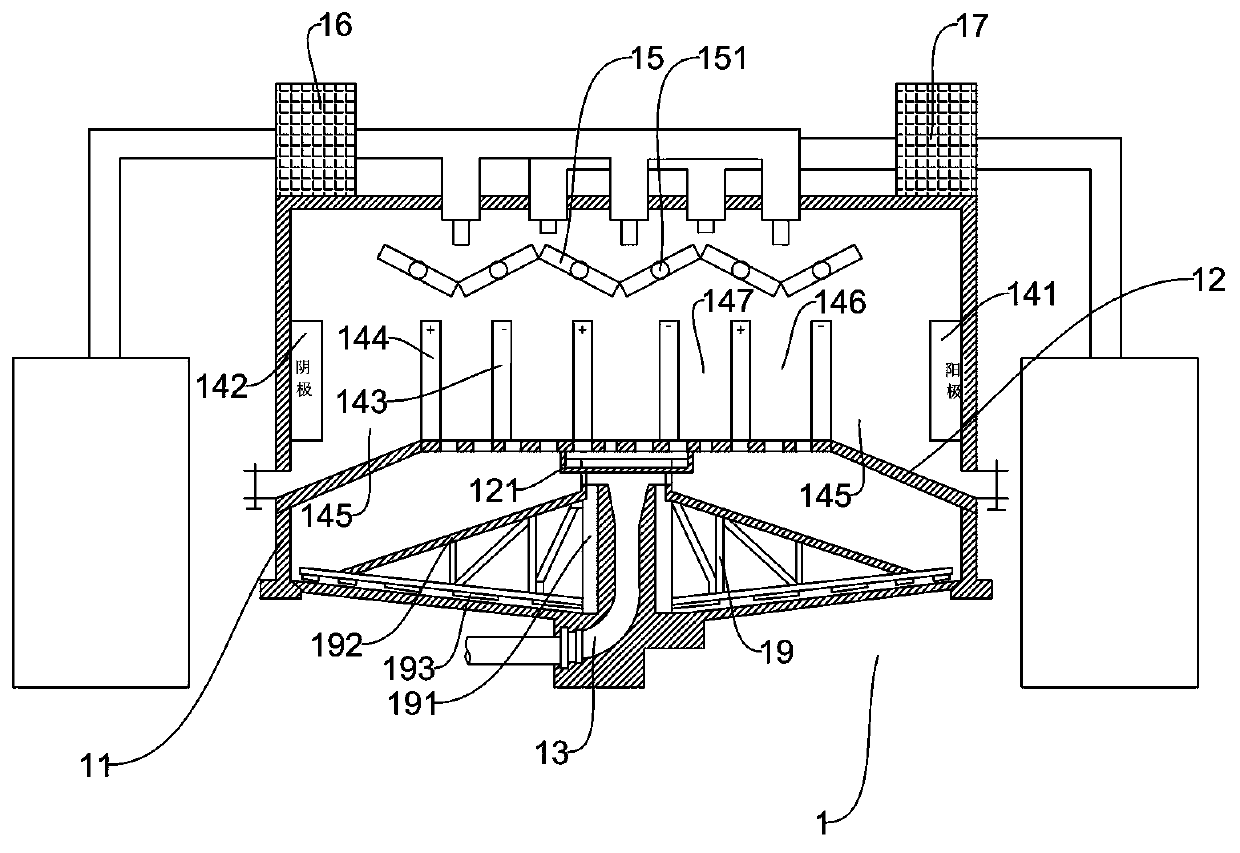

[0021] Such as figure 1 As shown, the desalination integrated device 1 includes a housing 11 and a partition 12 arranged in the housing 11 and provided with through holes. The partition 12 divides the inner cavity of the housing 11 from bottom to top into a precipitation zone and an evaporation and dialysis zone. The bottom of the housing 11 is provided with an introduction pipe 13, and the outlet of the introduction pipe 13 is located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com