Preparation method of lignosulfonate based three-source integrated flame retardants

A technology of lignosulfonate and sodium lignosulfonate, which is applied in the direction of fireproof coatings, etc., can solve problems such as ineffective utilization of components, environmental pollution, waste of lignin resources in papermaking black liquor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

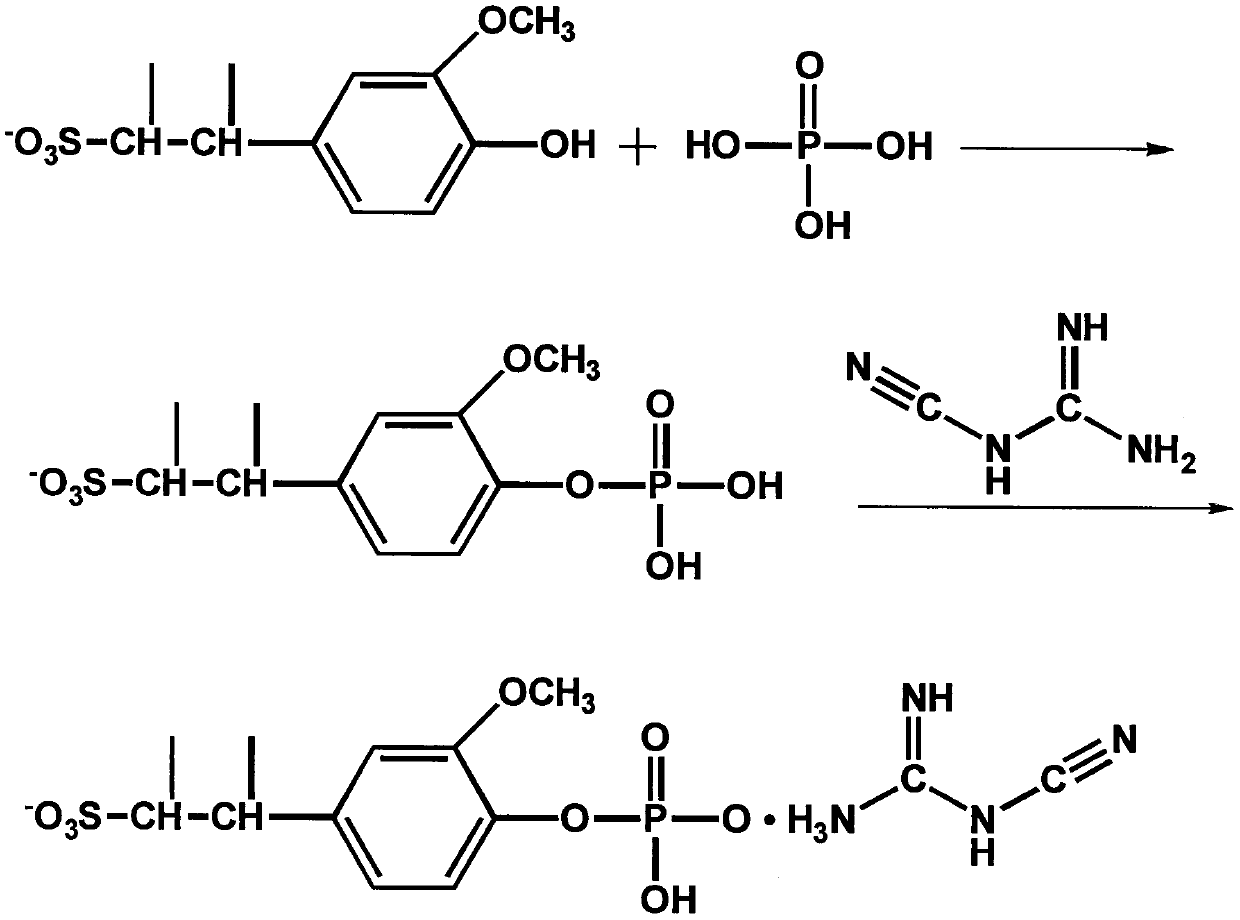

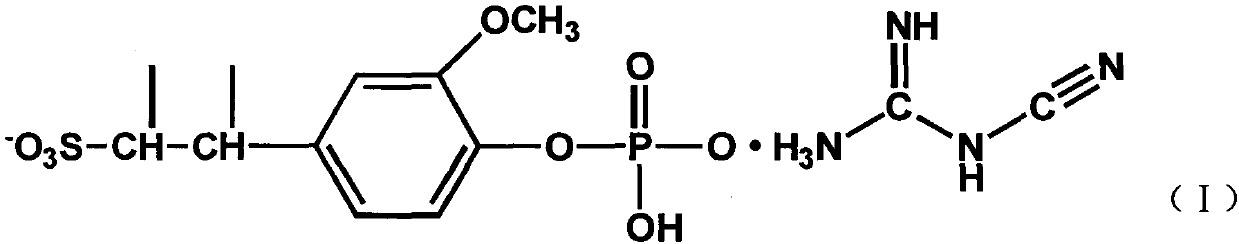

Method used

Image

Examples

Embodiment 1

[0019] Add 20g of 80% phosphoric acid solution into a 100ml three-necked flask, stir to raise the temperature, and add 5g of sodium lignosulfonate. After completely dissolving, heat up to 100°C, react for 8h, and then add 5g of dicyandiamide to the reaction solution after cooling down to room temperature For amine, the temperature was raised to 40°C, and the reaction was continued for 10 hours. Brown precipitates gradually precipitated in the system. After the reaction was completed, the product was left to stand, then filtered with suction, washed with methanol, and dried in vacuum to constant weight. Obtain lignosulfonate phosphate dicyandiamide salt.

Embodiment 2

[0021] Add 20g of 80% phosphoric acid solution into a 100ml three-neck flask, stir to raise the temperature, and add 5g of sodium lignosulfonate. After completely dissolving, heat up to 110°C, react for 8h, and then add 5g of dicyandiamide to the reaction solution after cooling down to room temperature For amine, the temperature was raised to 40°C, and the reaction was continued for 10 hours. Brown precipitates gradually precipitated in the system. After the reaction was completed, the product was left to stand, then filtered with suction, washed with methanol, and dried in vacuum to constant weight. Obtain lignosulfonate phosphate dicyandiamide salt.

Embodiment 3

[0023] Add 20g of 80% phosphoric acid solution into a 100ml three-neck flask, stir to raise the temperature, and add 5g of sodium lignosulfonate. After completely dissolving, heat up to 120°C, react for 8h, and then add 5g of dicyandiamide to the reaction solution after cooling down to room temperature For amine, the temperature was raised to 40°C, and the reaction was continued for 10 hours. Brown precipitates gradually precipitated in the system. After the reaction was completed, the product was left to stand, then filtered with suction, washed with methanol, and dried in vacuum to constant weight. Obtain lignosulfonate phosphate dicyandiamide salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com