A Method of NC Gradual Strengthening of Complicated Metal Surface

A metal surface, single-sided strengthening technology, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of high cost, low laser peening efficiency, poor strengthening uniformity, etc., to achieve overall performance and service behavior Improvement, Overall performance and service behavior optimization, and the effect of improving comprehensive service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

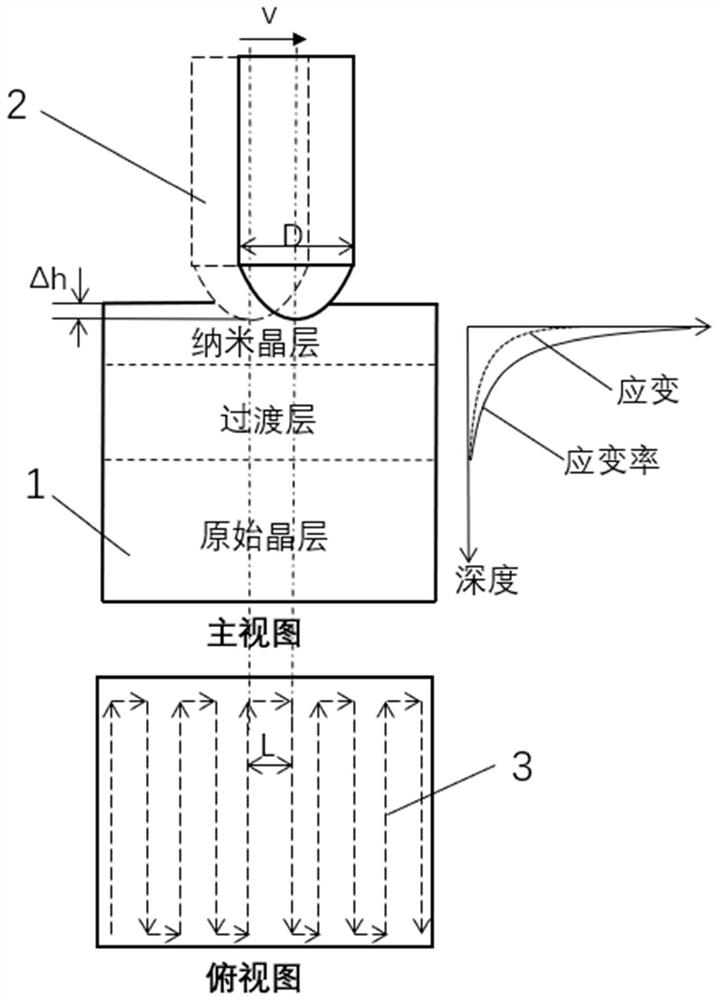

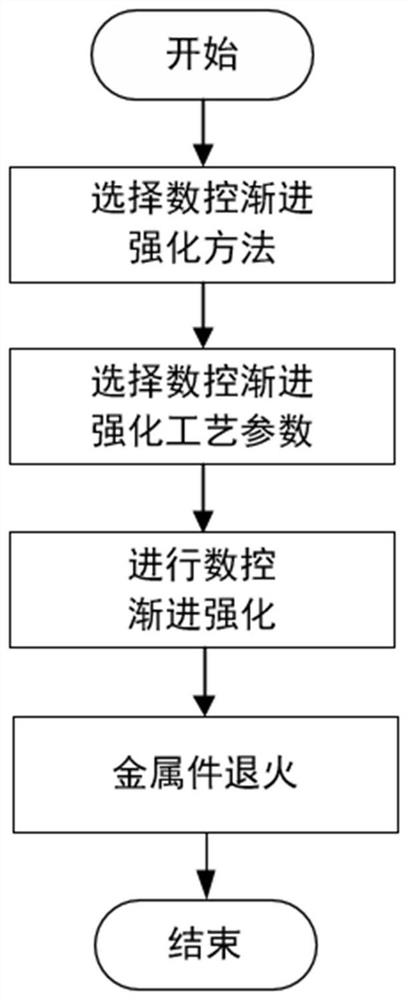

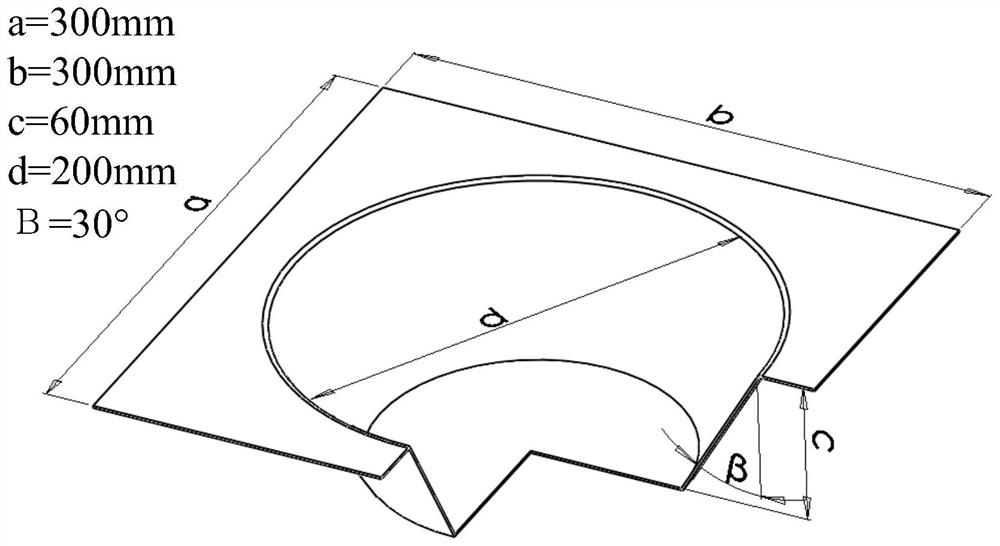

[0034] image 3 It is an aircraft skin part, the material is aluminum alloy AA2024, and its surface needs to be strengthened. in accordance with figure 2 The numerical control progressive strengthening process shown in the figure, the specific implementation steps of numerical control progressive strengthening are as follows:

[0035] (1) Select the CNC progressive strengthening method: the aircraft skin work area is mainly the outer surface, and the aluminum alloy AA2024 has low strength, so choose the CNC progressive single-sided grinding strengthening method, such as Figure 4 shown;

[0036] (2) Selection of numerical control progressive strengthening process parameters: Using the simulation method, firstly, under different combinations of process parameters, the numerical control progressive strengthening finite element simulation is carried out on the flat test piece to obtain data such as strain and strain rate. Then a material model based on dislocation density is ...

Embodiment 2

[0040] Figure 5 It is a schematic diagram of an aircraft engine blade, and the material is titanium alloy TC4. in accordance with figure 2 The numerical control progressive strengthening process shown in the figure, the specific implementation steps of numerical control progressive strengthening are as follows:

[0041] (1) Select the CNC progressive strengthening method: the working area of the aircraft engine blade is close to the two outer surfaces, the titanium alloy TC4 has higher strength, the CNC progressive double-sided rolling strengthening method, the tool head is a ball, such as Image 6 shown;

[0042] (2) Selection of CNC progressive strengthening process parameters: Using the test method, firstly, the flat test piece is subjected to CNC progressive double-sided rolling strengthening under different combinations of process parameters. Then perform microscopic characterization, and select the combination of process parameters to realize the nanogradient stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com