Oil special for polylactic acid cigarette tow and preparing method of oil

A technology of polylactic acid cigarette and oil agent, applied in the field of cigarette tow, can solve the problems of not meeting the requirements of cigarette tow additives, poor compatibility of polylactic acid tow, insufficient stability of oil agent, etc., and achieve a delicate taste. , Good compatibility, good oil stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

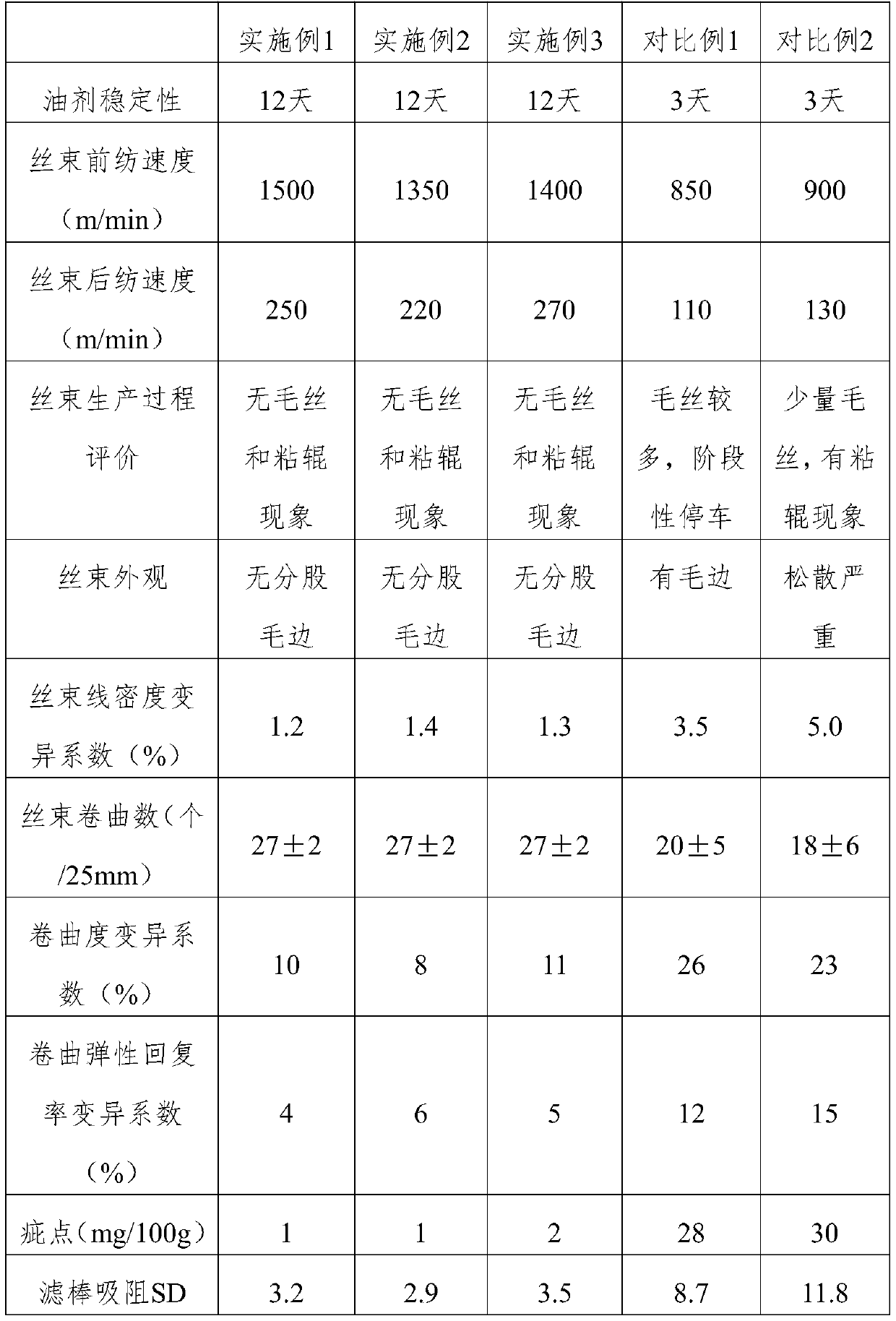

Examples

Embodiment 1

[0023] 1) Crude raw materials include: polyethylene glycol 400 dilaurate (PEG400DL) 40 parts, castor oil polyoxyethylene ether (HEL-20) 20 parts, fatty alcohol ether phosphate potassium salt (MOA-3PK-70) 15 parts 15 parts of polyoxyethylene laurate (LAE-9) and 10 parts of deionized water (0.3us / cm).

[0024] 2) The oil agent components include: 10000 parts of deionized water with a conductivity of 0.3us / cm, 100 parts of crude oil, 20 parts of dodecyl dimethyl betaine (BS-12) and sorbitan fatty acid ester ( S-40) 15 parts.

[0025] 3) Crude oil blending

[0026] The various components of crude oil are added to the ultrasonic mixing reactor according to the process ratio requirements, the set temperature is 45°C, the frequency is 40KHz, and the time is 30min.

[0027] 4) Oil configuration

[0028] Add each component into a high-speed shear emulsifier according to the oil concentration ratio, stir at 40°C and 300r / min at high speed for 20 minutes, and stand for 10 minutes befo...

Embodiment 2

[0030] 1) Crude raw materials include: polyethylene glycol 400 dilaurate (PEG400DL) 35 parts, castor oil polyoxyethylene ether (HEL-20) 20 parts, fatty alcohol ether phosphate potassium salt (MOA-3PK-70) 20 parts 15 parts of polyoxyethylene laurate (LAE-9) and 10 parts of deionized water (0.3us / cm).

[0031] 2) The oil agent components include: 10000 parts of deionized water with a conductivity of 0.3us / cm, 150 parts of crude oil, 20 parts of dodecyl dimethyl betaine (BS-12) and sorbitan fatty acid ester ( S-40) 15 parts.

[0032] 3) Crude oil blending

[0033] The various components of crude oil are added to the ultrasonic mixing reactor according to the process ratio requirements, and the set temperature is 40°C, the frequency is 45KHz, and the time is 40min.

[0034] 4) Oil configuration

[0035] According to the oil concentration ratio, each component was added into a high-speed shear emulsifier, stirred at a high speed for 20 minutes at 35°C and 300r / min, and left to s...

Embodiment 3

[0037] 1) Crude raw materials include: polyethylene glycol 400 dilaurate (PEG400DL) 35 parts, castor oil polyoxyethylene ether (HEL-20) 15 parts, fatty alcohol ether phosphate potassium salt (MOA-3PK-70) 20 parts 20 parts, 20 parts of polyoxyethylene laurate (LAE-9) and 10 parts of deionized water (0.3us / cm).

[0038] 2) The oil agent components include: 10000 parts of deionized water with a conductivity of 0.3us / cm, 120 parts of crude oil, 20 parts of dodecyl dimethyl betaine (BS-12) and sorbitan fatty acid ester ( S-40) 15 parts.

[0039] 3) Crude oil blending

[0040] The various components of crude oil are added to the ultrasonic mixing reactor according to the process ratio requirements, the set temperature is 40°C, the frequency is 50KHz, and the time is 45min.

[0041] 4) Oil configuration

[0042] According to the oil concentration ratio, each component was added into a high-speed shear emulsifier, stirred at a high speed for 30 minutes at 42°C and 300 r / min, and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com