Hydraulic silent directional rock breaking device

A technology of crushing device and rock mass, applied in road construction and mining fields, can solve the problems of lack of efficiency, large amount of expansion agent and high cost, and achieve the effect of improving crushing efficiency and reducing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

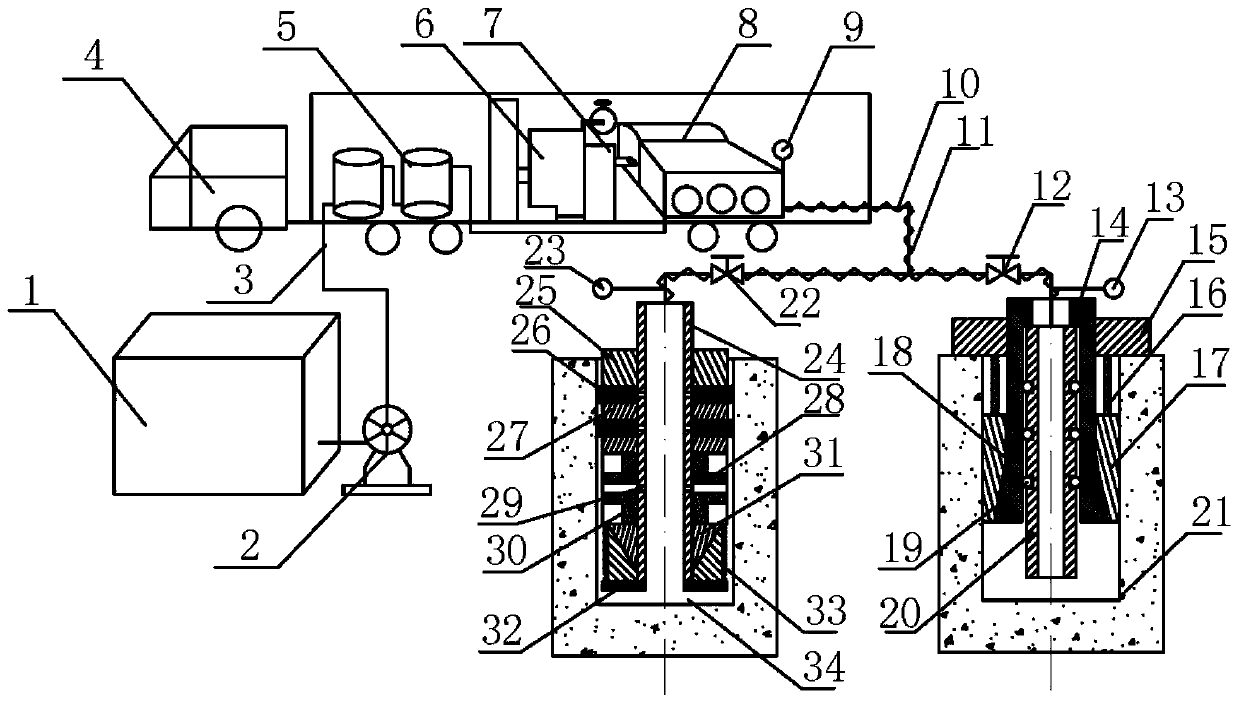

[0016] The present invention will be further described below in conjunction with accompanying drawing:

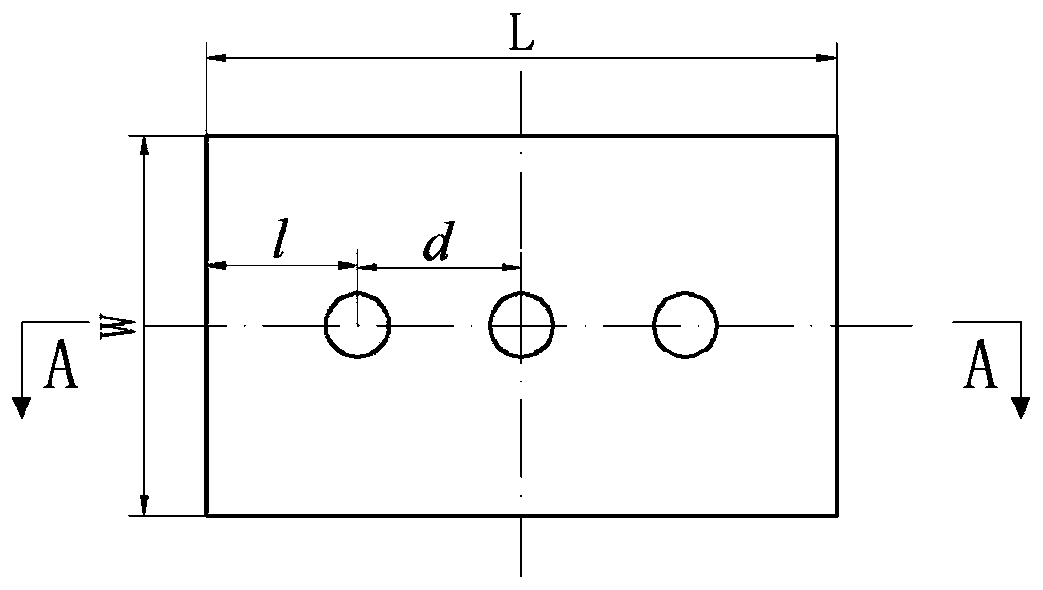

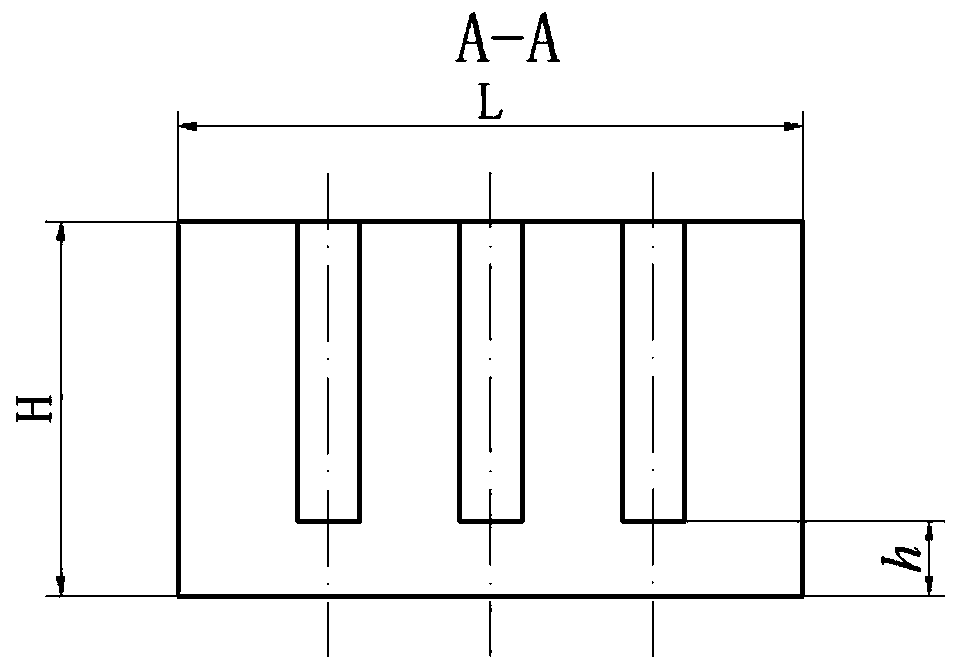

[0017] Such as figure 1As shown, the rock mass hydraulic silent directional crushing device of the present invention comprises a water tank 1, a centrifugal pump 2, a water hose 3, a truck 4, a filter 5, a diesel engine 6, a gearbox 7, a high-pressure pump 8, and a high-pressure pump pressure Table 9. High-pressure hose 10, protective sleeve 11, high-pressure valve with extrusion-type sealing structure 12, pressure gauge with extrusion-type sealing structure 13, limit block 14, compression nut 15, pressure rod 16, special wedge-shaped sealing block 17, Pull-up rod 18, o-ring 19, pressure pipe 20, rock 21, hydraulic seal structure high-pressure valve 22, hydraulic seal structure pressure gauge 23, diversion tube 24, pressure block 25, rubber plug 26, spacer 27, upper piston 28, diversion hole 29, lower piston 30, wedge-shaped body 31, support block 32, ferrule 33, eyelet 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com