Anti-backfire nozzle and liquid rocket engine with the nozzle

A liquid rocket and engine technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as limited propellant capacity and cannot meet the needs of high-thrust engines, and achieve excellent work performance and meet the needs of efficient transportation , the effect of increasing the circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail with reference to the drawings and specific examples.

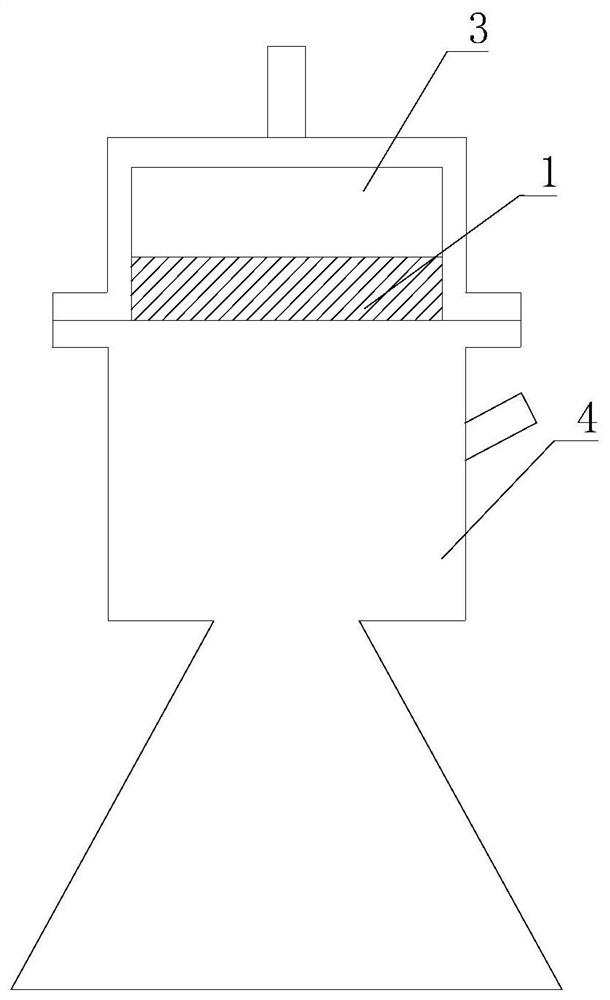

[0032] See 1 to 3 As shown, the embodiment of the present invention provides an anti-flashback nozzle, which is used for connecting the effusion cavity 3 and the combustion chamber 4 of an engine, and comprises a body 1.

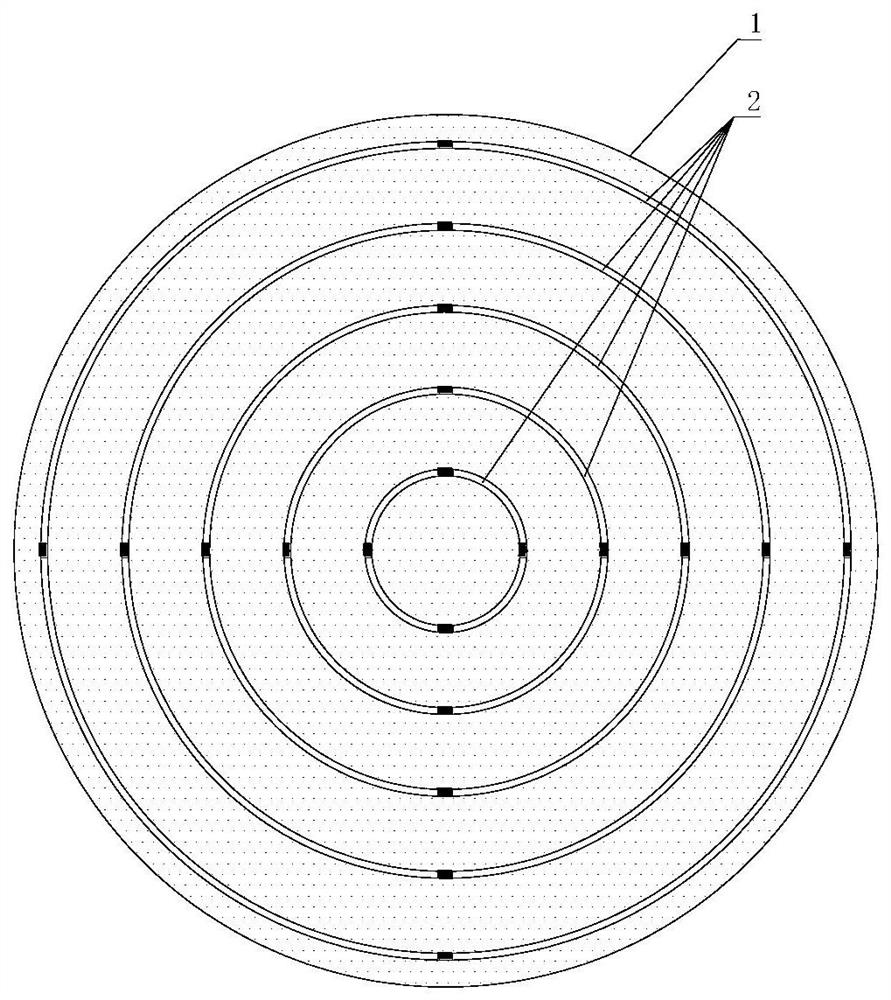

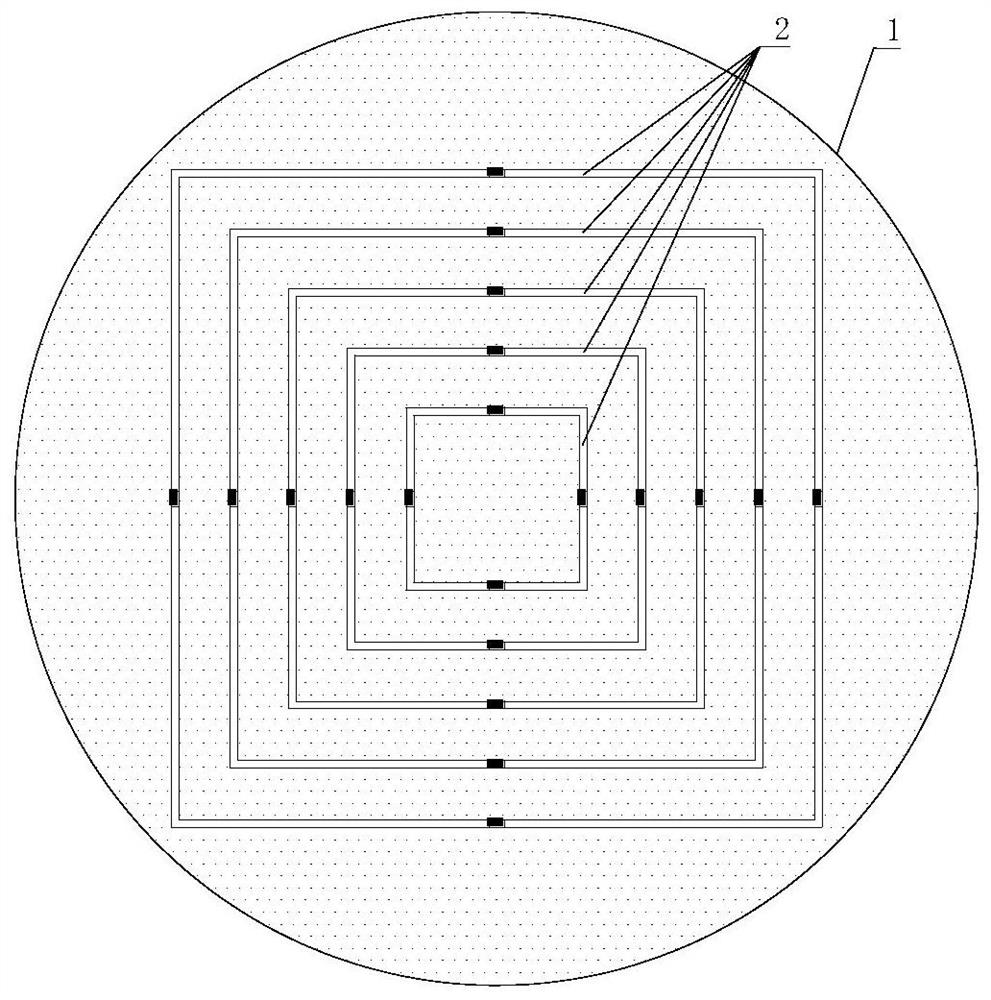

[0033] A body 1, the surface of which is provided with a plurality of slits 2, each slit 2 is evenly distributed on the surface of the body 1, and the slits 2 do not intersect the edge of the body 1. The slits 2 penetrate through the body 1 along the height direction of the body 1 and communicate the effusion cavity 3 with the combustion chamber 4, so that the propellant in the effusion cavity 3 flows into the combustion chamber 4 through the slits 2.

[0034] The anti-backfire nozzle provided by the invention adopts the body 1 to be provided with a plurality of slits 2 penetrating through the body 1, which can quickly dissipate heat, inhibit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com