Antistatic fabric and manufacturing method thereof

A production method and antistatic technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of easy aging of organic conductive polymers, restricted carbon-based dyeing, expensive metal systems, etc., and achieve excellent antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] a)SiO2 2 Preparation of hydrosols

[0043] At room temperature, add orthoethyl silicate (TEOS) dropwise at a rate of 1 drop / s into a certain amount of glacial acetic acid (HAc) and water mixture under high-speed stirring, and stir rapidly for 3 hours until a uniform and transparent SiO 2 Sol; Wherein, the mass fraction of Si is 2%, n(TEOS):n(HAc)=1:2.6;

[0044] b) Conductive AZO@Ti0 2 Preparation of nanowhiskers

[0045] TiO 2 Nanoparticles and K 2 CO 3 The solid is mixed by ball milling, high temperature sintering, boiling, suction filtration, and drying to prepare potassium titanate whiskers, which are then pickled and calcined to make TiO 2 nano whiskers;

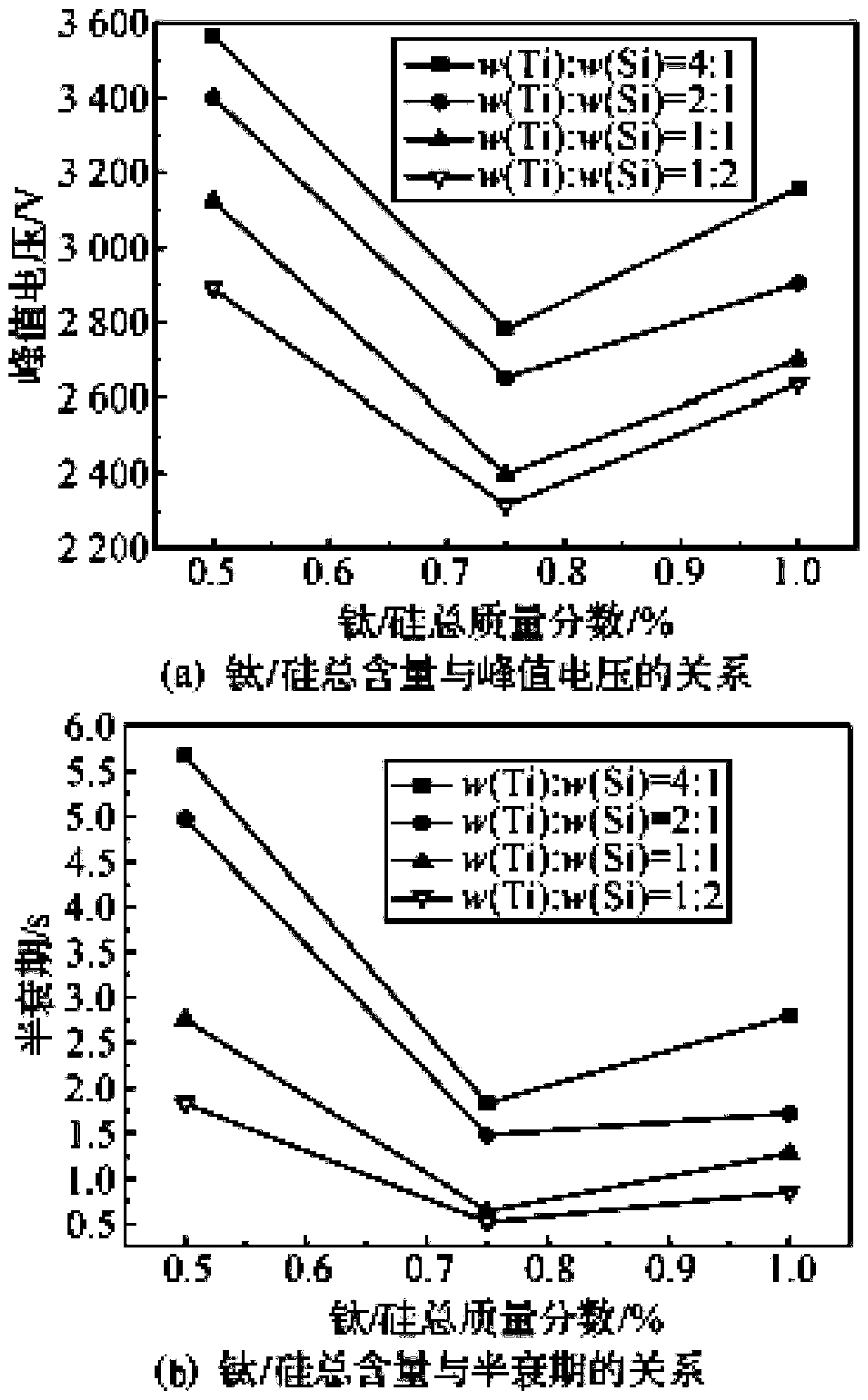

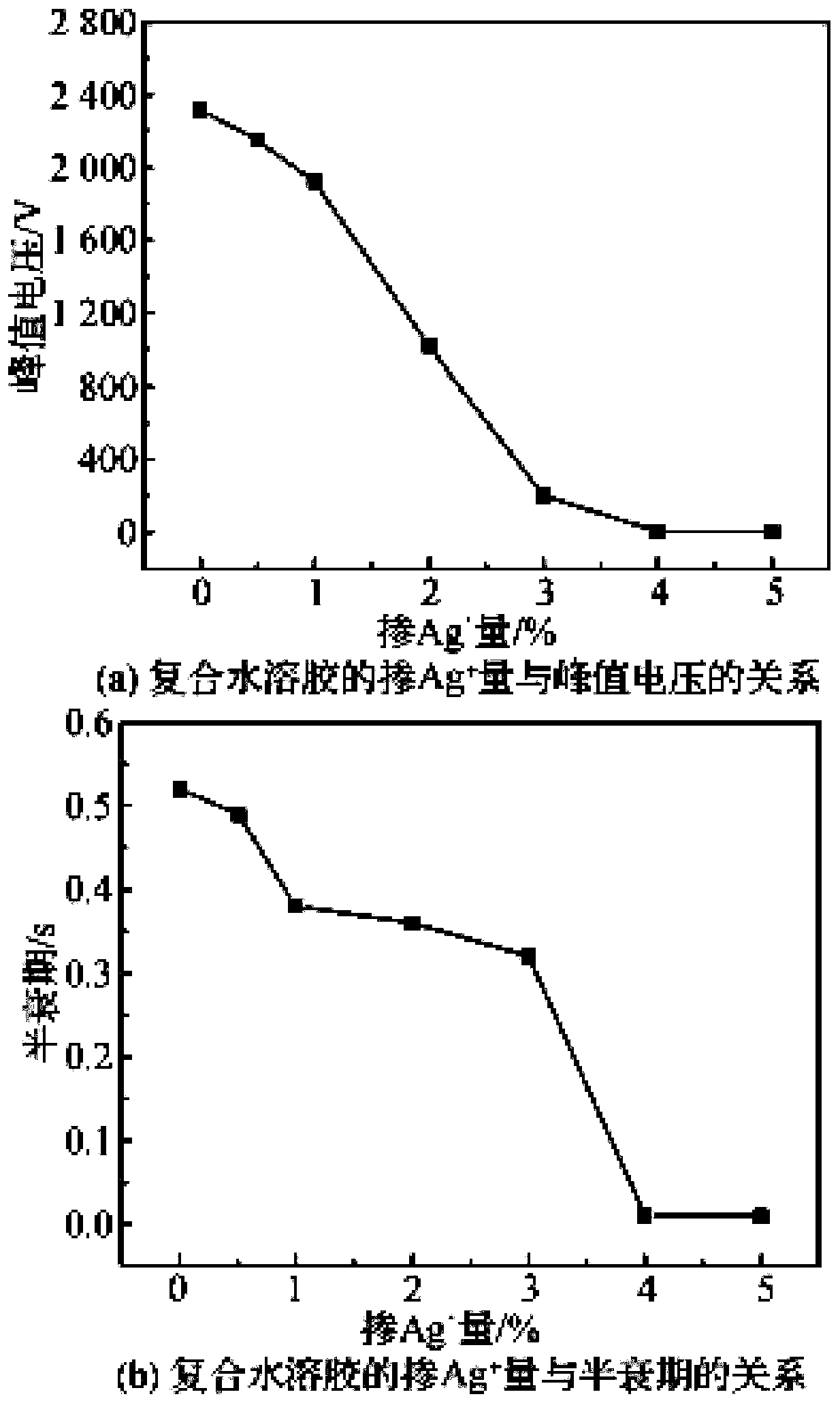

[0046] Formulated TiO 2 The suspension oil of nano whiskers was ultrasonicated for 30 minutes, the suspension was poured into a three-necked flask and stirred at a constant speed, and a thermometer was inserted on one side to monitor the reaction temperature. 2 After the temperature of the nano-whisker ...

Embodiment approach

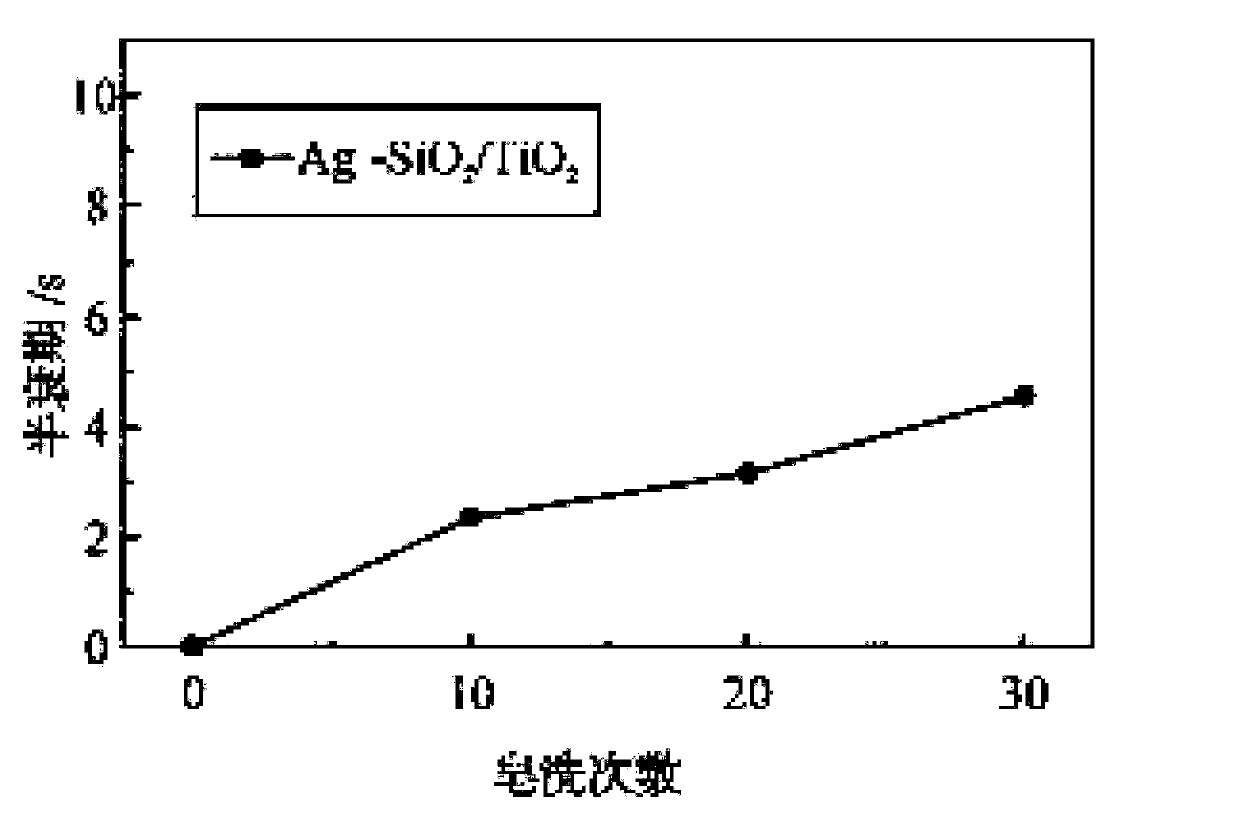

[0073] Another preferred embodiment: an antistatic fabric, including a fabric interwoven with warp threads and weft threads, and the fabric is treated with the method for making the antistatic fabric in the first preferred embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com