Microstructure liquid self-driven flat plate type loop heat pipe with branches

A loop heat pipe and microstructure technology, applied in indirect heat exchangers, lighting and heating equipment, electrical equipment structural parts, etc., can solve the problems of boiling pool drying, complicated startup, temperature overshoot, etc., to promote uniform distribution , the effect of increasing the heat exchange area and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

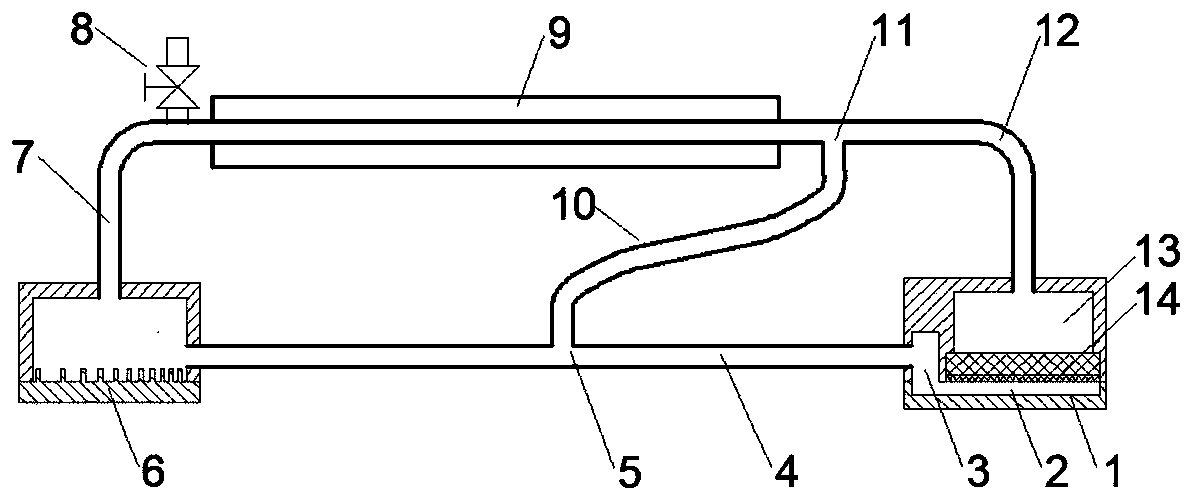

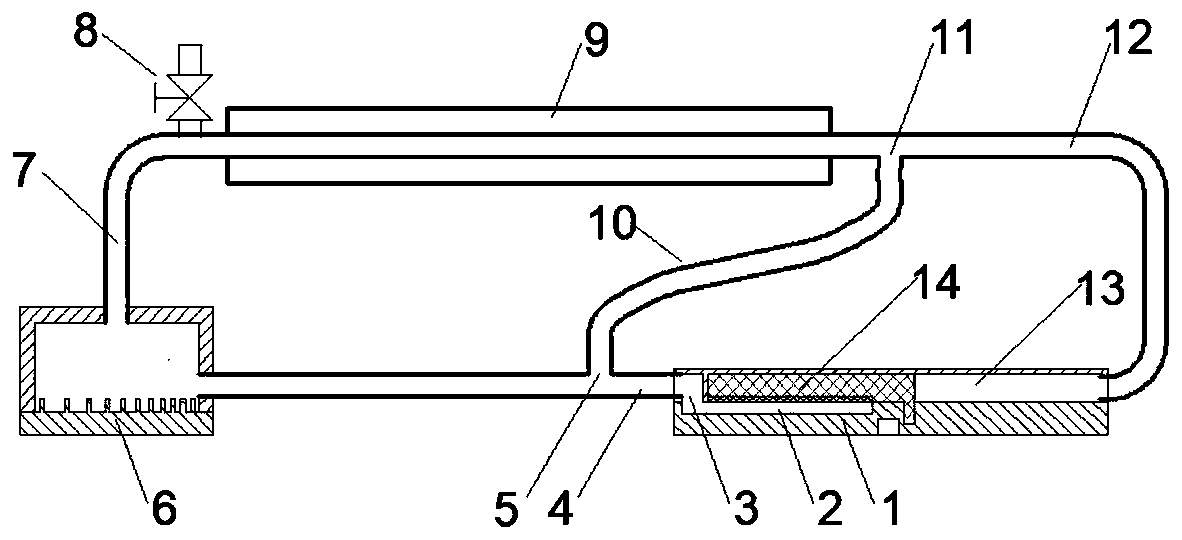

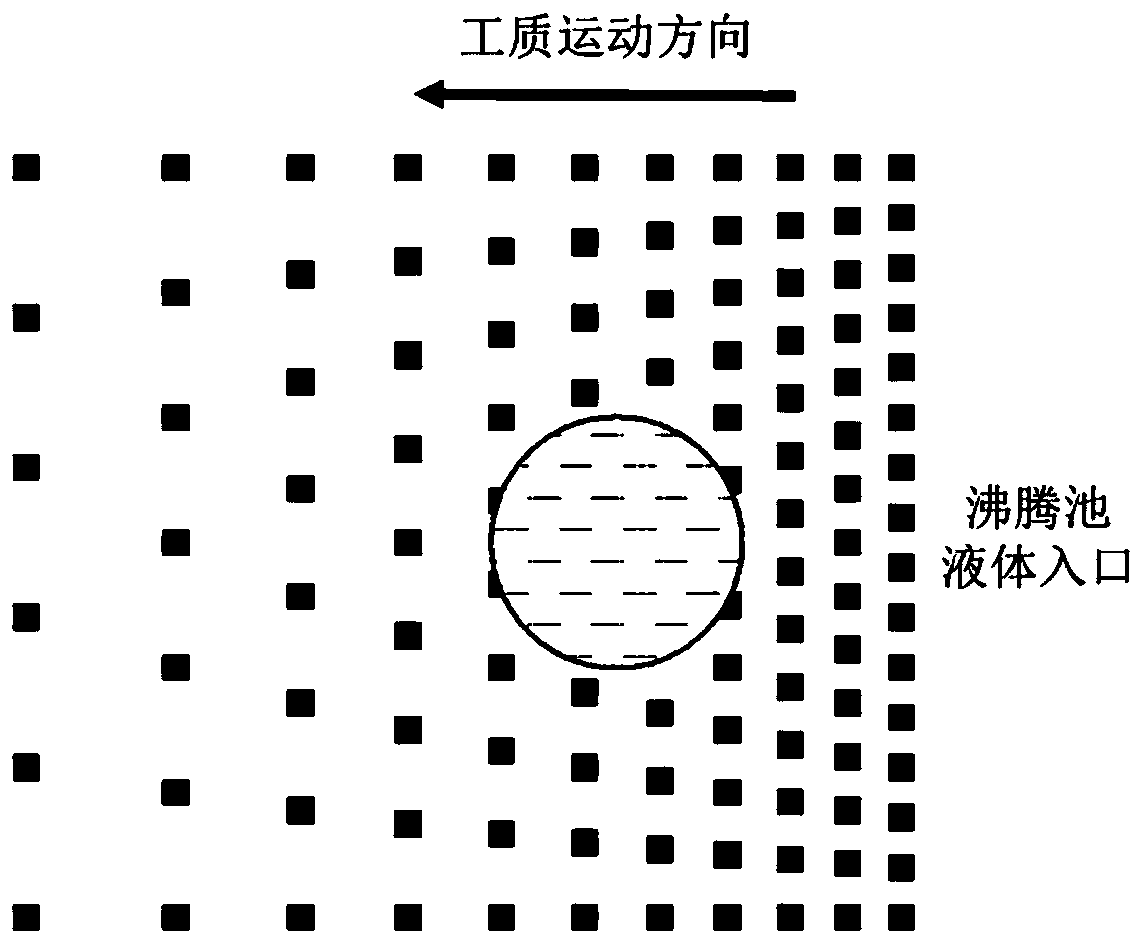

[0030] see figure 1 and figure 2 , a microstructure liquid self-driven plate loop heat pipe with a branch circuit of the present invention mainly includes an evaporator 1 , a boiling pool 6 , a condenser 9 , a branch circuit 10 and a compensation cavity 13 . The evaporator 1 is a flat plate, including upper and lower parts, and the upper and lower parts are welded and sealed. The inner bottom of the evaporator 1 is provided with a steam channel 2, and a capillary core 14 is provided above the steam channel 2. The capillary core 14 is nickel-copper composite. Structured capillary core. The capillary wick of the nickel-copper composite structure comprises sintered nickel powder 14.1 arranged on sintered copper powder 14.2.

[0031] One side of the steam channel 2 is provided with a gas collecting tank 3, and the steam channel 2 communicates with the gas collecting ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com