A fiber grating acceleration sensor with temperature compensation and its measurement method

A technology of acceleration sensor and optical fiber grating, which is applied in speed/acceleration/shock measurement, acceleration measurement using inertial force, and acceleration measurement. Install vibration detection and other problems to achieve the effect of simple structure, distributed detection and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

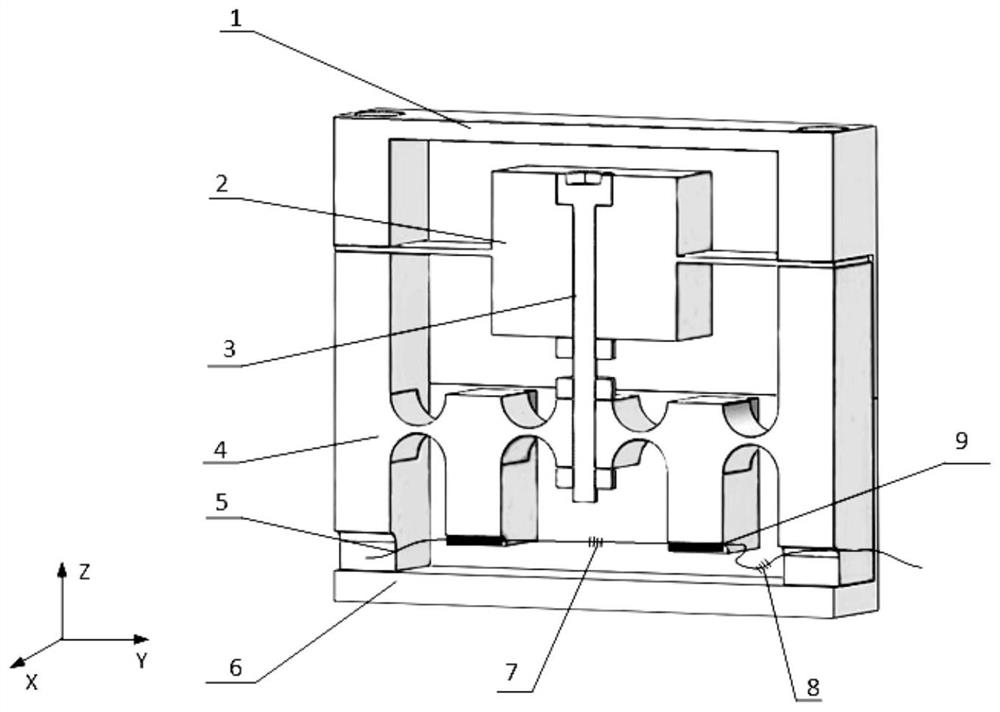

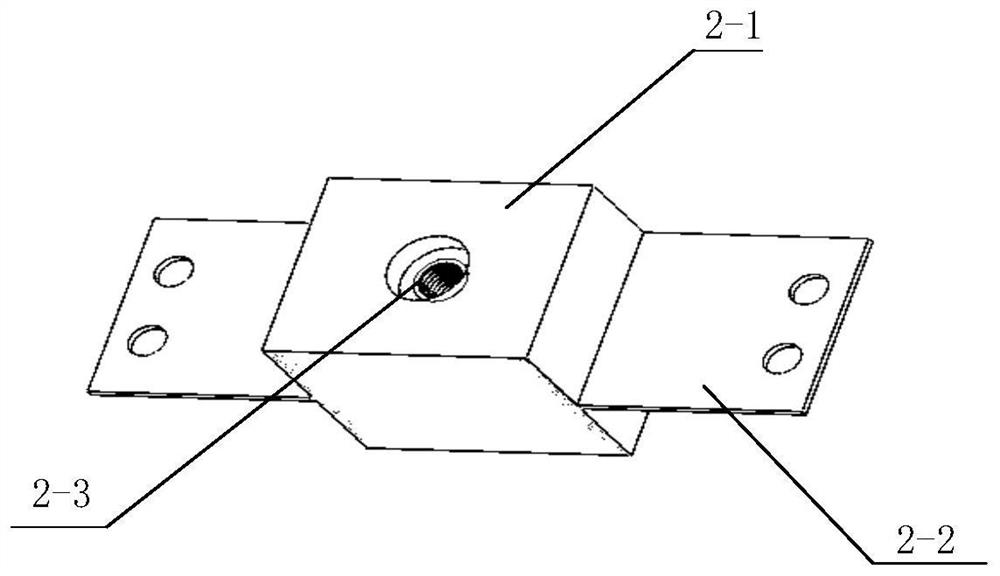

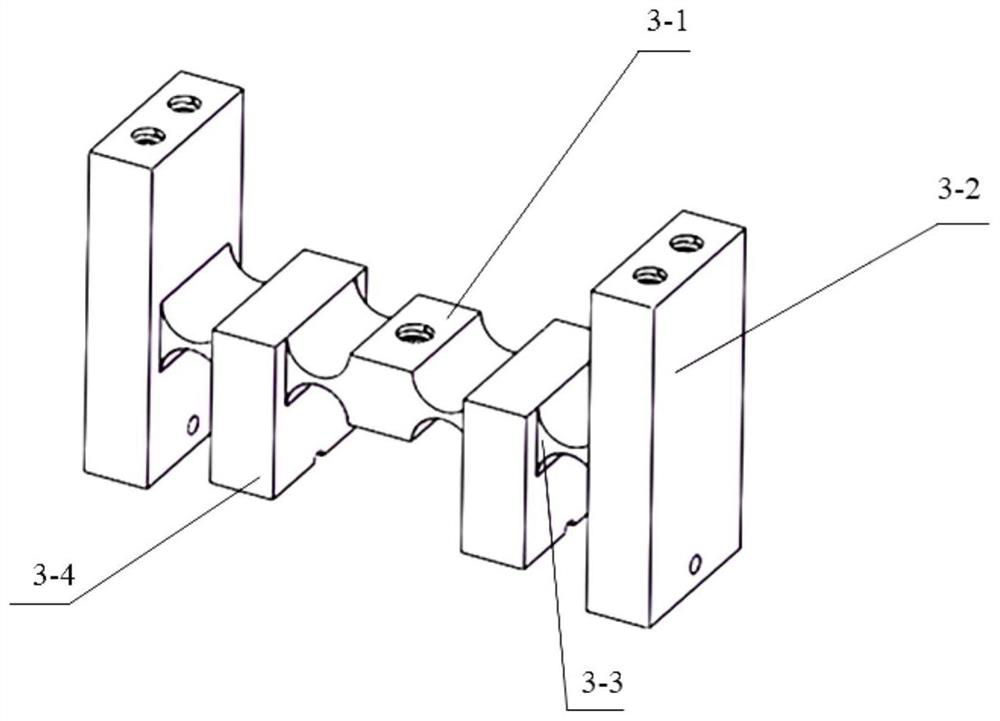

[0060] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-4 As shown, a miniaturized fiber grating acceleration sensor with temperature compensation is characterized in that it includes an upper shell 1, a lower shell 6, a mass block 2 located between the upper and lower shells, and two rectangular elastic plates are arranged symmetrically on both sides of the mass block. Plate, the middle part of the mass block 2 is provided with a threaded hole for connecting with the screw 3, the bottom of the screw is connected to the elastic body 4, the elastic body 4 includes columnar outer walls 3-2 on both sides, and a pair of pillars 3-4 are arranged between the columnar outer walls And the connection block 3-1 located in the middle, the outer wall and the pillar, and the pillar and the connection block are all connected by a hinge 3-3, the bottom of the screw rod 3 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com