Multi-material manipulator

A manipulator, multi-material technology, applied in the field of manipulators, can solve the problems of low rigidity of constituent materials, inability to withstand large loads or self-weight, etc., and achieve the effect of meeting strength requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

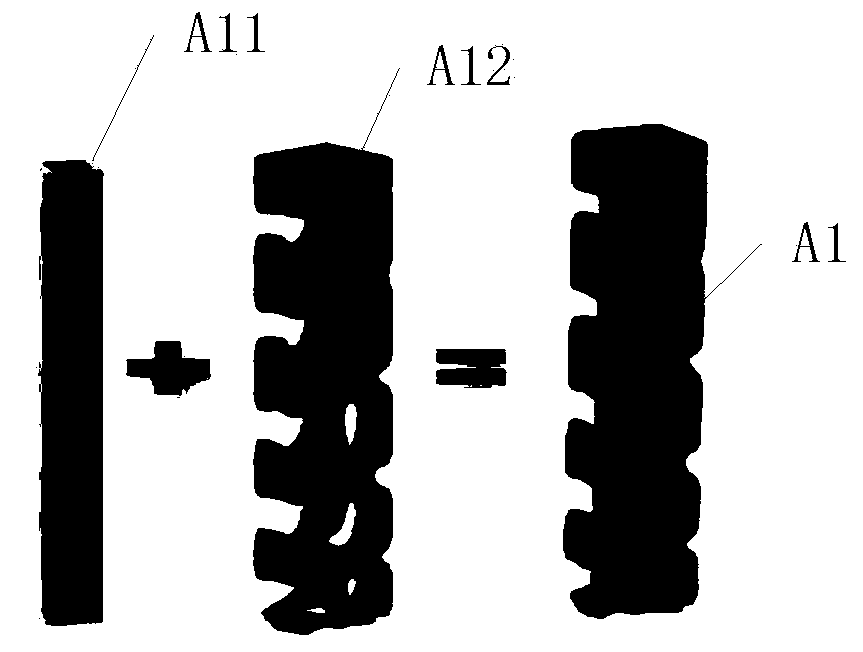

[0041] Such as figure 1 As shown, a multi-material manipulator according to an embodiment of the present invention is provided. The multi-material manipulator A1 includes a soft material part A11 obtained by integral injection molding (the prior art) and a hard material part A12 obtained by a 3D method. The material part A12 is hollow, and the soft material matching A11 is arranged in the hollow of the hard material part A12.

[0042] In another embodiment, the soft material part A11 refers to a hollow rectangular tube made of silica gel; the hard material part A12 refers to a hollow hinge made of TPE.

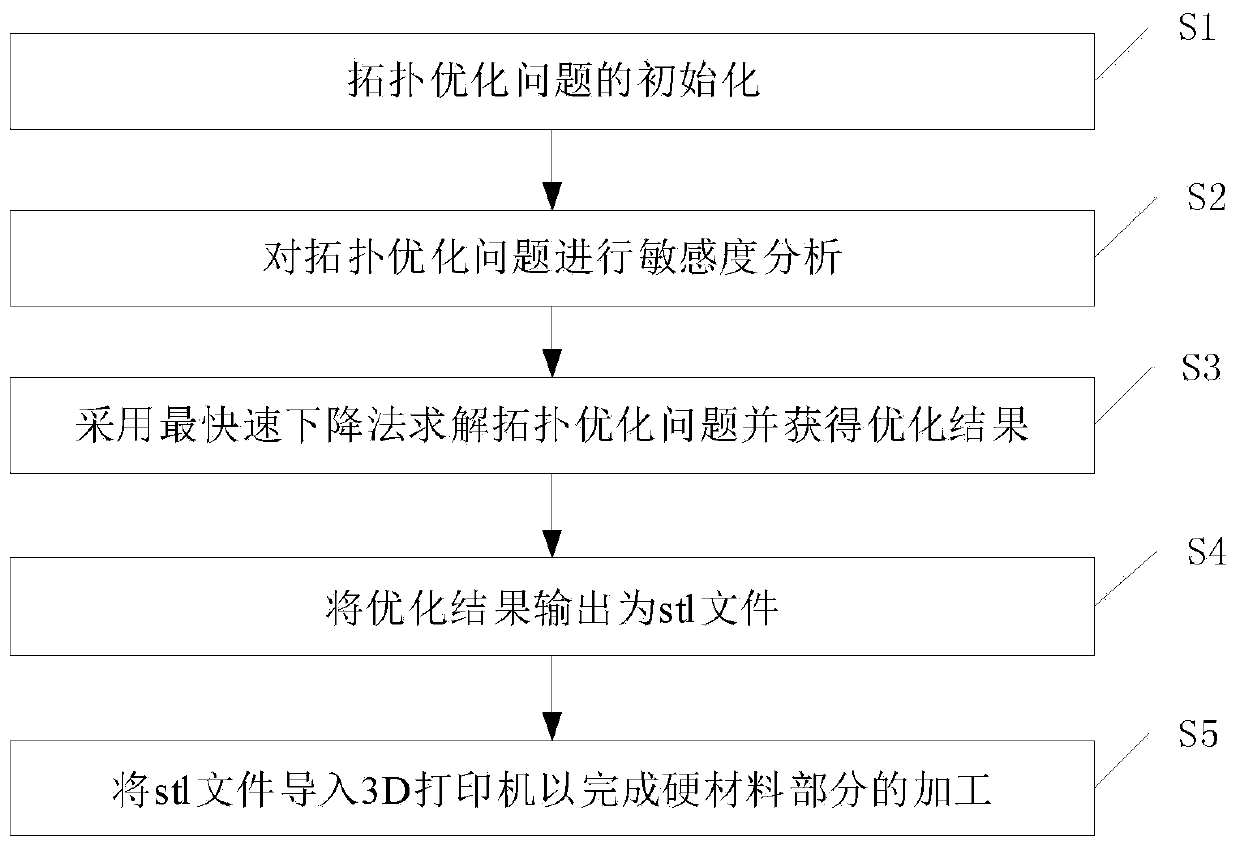

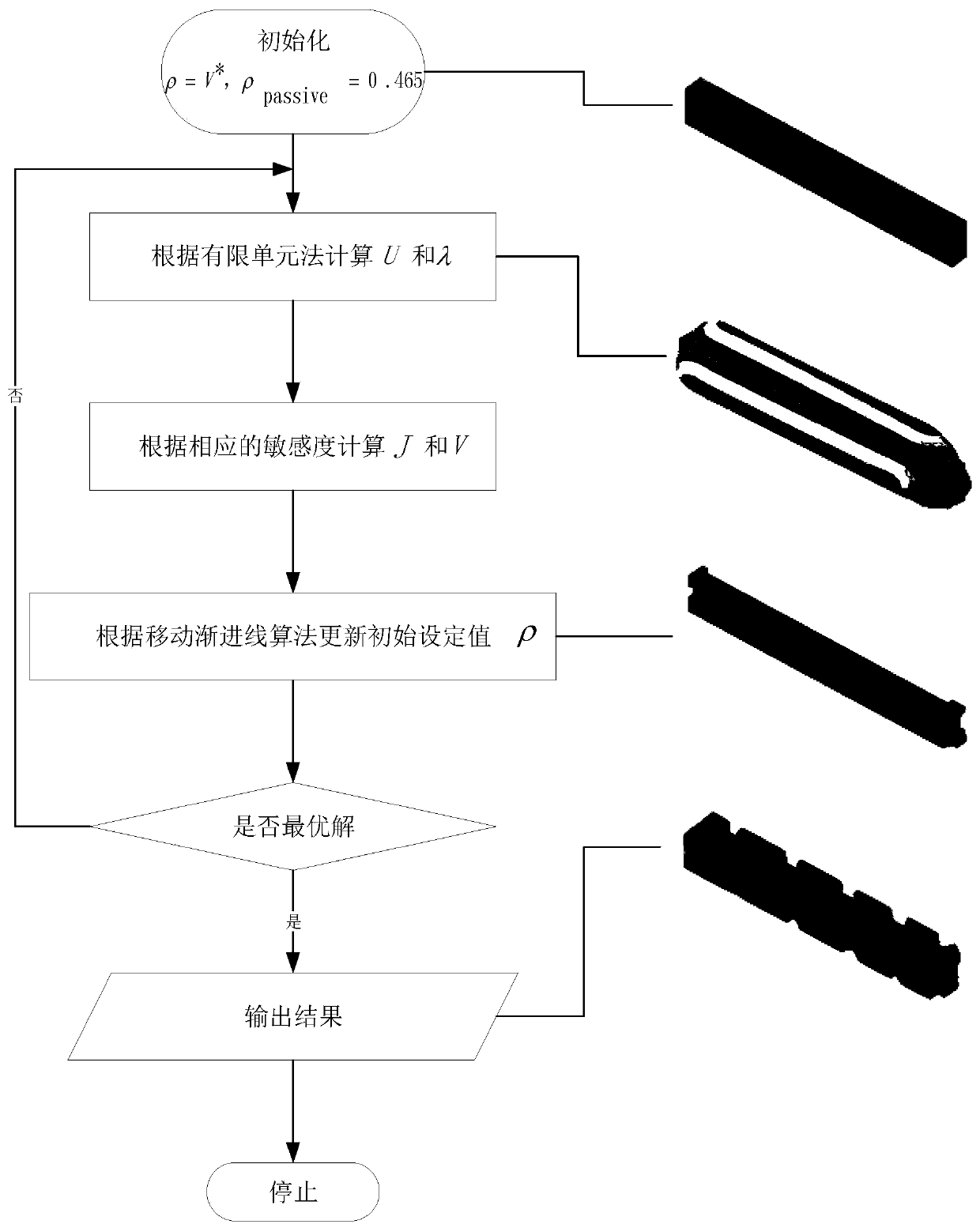

[0043] Such as figure 2 with image 3 As shown, the steps to obtain the hard material part A12 through 3D are as follows:

[0044] S1: Initialization of the topology optimization problem: given the design domain, design variables and constraints of the hollow cuboid of the hard material part A12;

[0045] The initialization of the topology optimization problem is simplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com