Totally-enclosed motor with heat dissipation function

A fully enclosed and functional technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of insufficient heat removal, front bearing temperature rise, poor cooling effect, etc., to ensure reliability and safety, Promote flow cooling and avoid the effect of solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

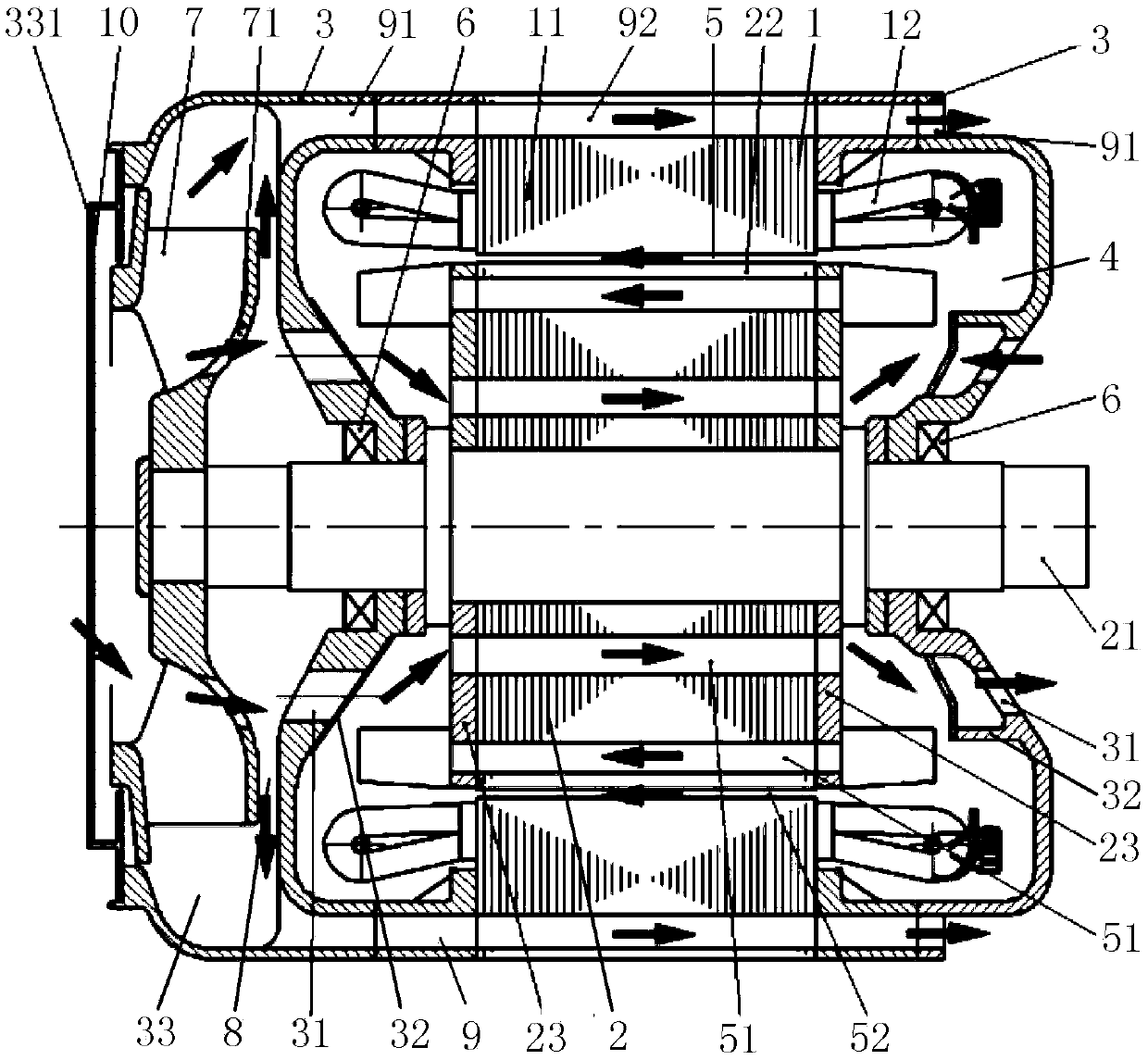

[0026] Such as figure 1 As shown, the fully enclosed motor with heat dissipation function in this embodiment includes a stator assembly 1 , a rotor assembly 2 and two sealing end covers 3 . The stator assembly 1 includes a stator core 11 and a winding 12 , both ends of the stator core 11 are respectively connected to the sealing end covers 3 on the corresponding sides, and the winding 12 is wound on the stator core 11 . The rotor assembly 2 includes a rotating shaft 21 , a rotor core 22 and two rotor pressure rings 23 , wherein the rotating shaft 21 passes through the two sealing end covers 3 , and the rotating shaft 21 is surrounded by the sealing end cover 3 and the stator assembly 1 to form a motor sealing space 4 ; The rotor core 22 is fixedly assembled on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com