A Composite Air Suspension System Without Matching Thrust Rods

An air suspension and composite technology, applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve the problems of high risk of frame cracking, poor vehicle passability, and small crack risk, so as to improve vehicle passability and improve Reliability and the effect of reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

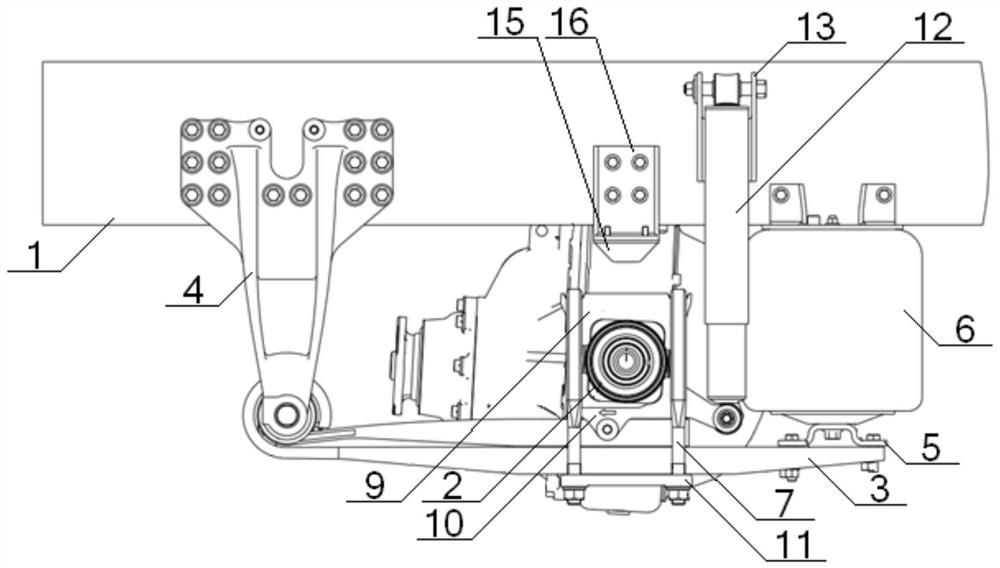

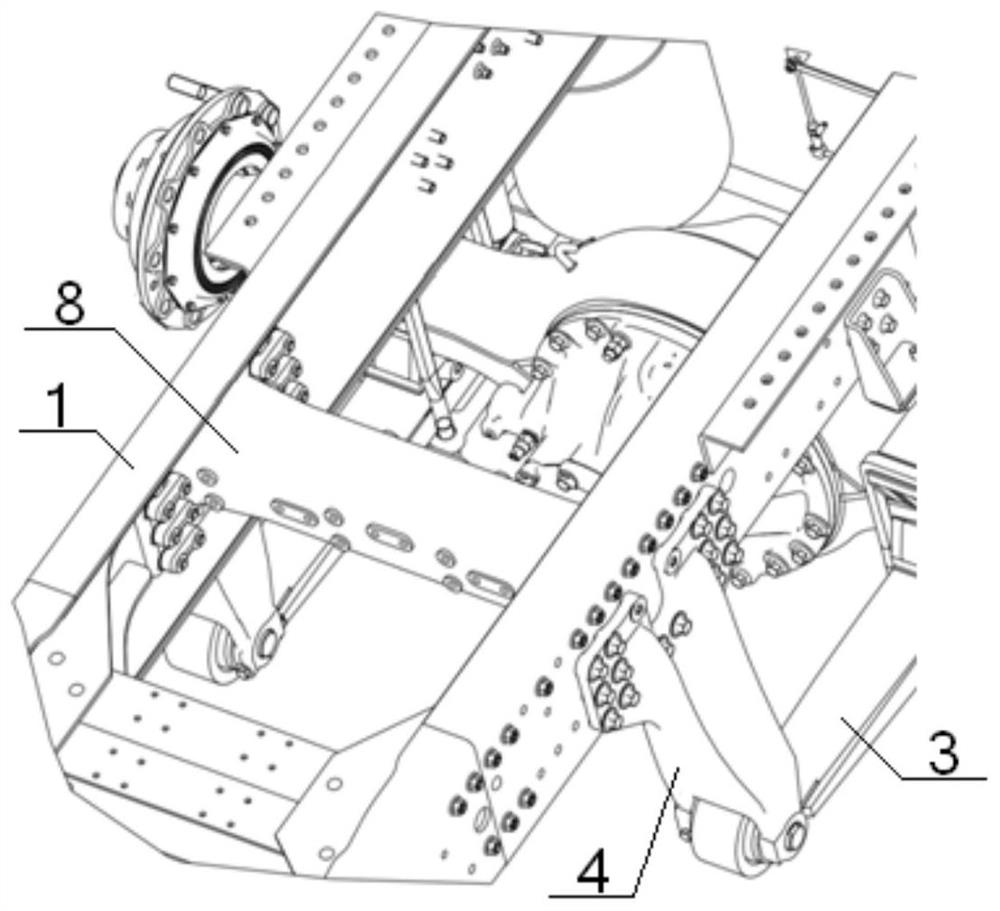

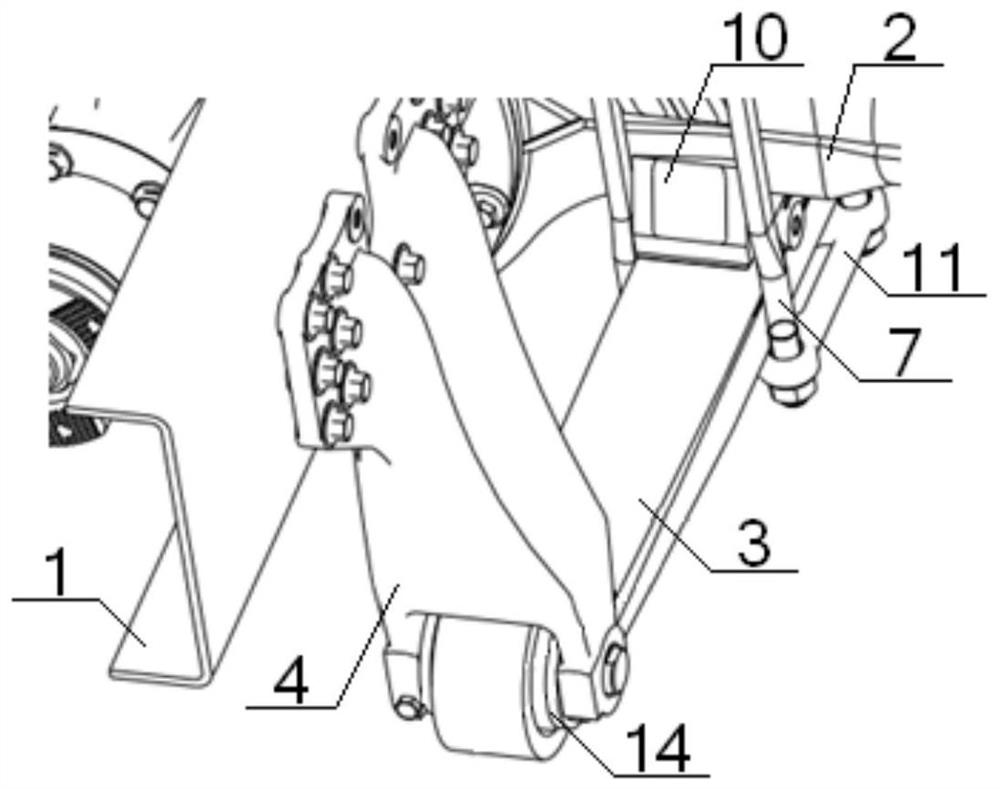

[0066] see Figure 1 to Figure 5 , a composite air suspension system that does not match the thrust rod, including a vehicle frame 1, an axle 2, and a guide arm 3, one end of the guide arm 3 is connected to the vehicle frame 1 through a guide arm bracket 4, and the guide arm 3 The other end of the air spring beam 5 is connected with one end of the air spring 6, the other end of the air spring 6 is connected with the vehicle frame 1, and the middle part of the guide arm 3 is connected with the axle 2 through the U-bolt 7; the composite The type air suspension system also includes a frame beam 8, the end of the frame beam 8 is connected with the guide arm bracket 4 through the vehicle frame 1, the guide arm 3 is located below the axle 2, and the guide arm 3 is provided with a The U-shaped bolt base plate 11, the lower cover plate 10 is arranged between the guide arm 3 and the axle 2, and the upper cover plate 9 is arranged above the axle 2, and the U-shaped bolt 7 spans the uppe...

Embodiment 2

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] see Figure 1 to Figure 12 , the lower cover plate 10 comprises a base plate 101 and a No. 1 riser 102 and a No. 2 riser 103 symmetrically arranged on the upper end thereof, and the U-shaped groove formed by the base plate 101, the No. 1 riser 102 and the No. 2 riser 103 is used When the axle 2 is arranged, the middle part of the base plate 101 is provided with a No. 1 bolt hole 104 connected with the guide arm 3 , and a diagonal brace 105 is provided between the side of the No. 1 riser 102 away from the No. 2 riser 103 and the base plate 101 , the No. 2 vertical plate 103 is symmetrically provided with a No. 1 horizontal plate 106 and a No. 2 horizontal plate 107 away from the side of the No. 1 vertical plate 102, and the No. 1 horizontal plate 106 and the No. 2 horizontal plate 107 are all connected to the bottom plate 101, A reinforcing plate 108 is arranged between the No. 1 horizontal plate 106...

Embodiment 3

[0071] Basic content is the same as embodiment 1, the difference is:

[0072] see Figure 1 to Figure 8 , the guide arm bracket 4 includes a mounting plate 41 and a No. 1 support plate 42 and a No. 2 support plate 43 that are symmetrically arranged. One end is provided with a pair of No. 1 flanges 44, and one end of the No. 2 support plate 43 is connected with the mounting plate 41, and the other end of the No. 2 support plate 43 is provided with a pair of No. 2 flanges 45. The No. 1 support plate 42 No. 3 horizontal plate and No. 4 horizontal plate are sequentially arranged from top to bottom between No. 2 support plate 43, one end of No. 3 horizontal plate is connected with mounting plate 41, and the other end of No. 3 horizontal plate is connected with No. 5 vertical plate The middle part of the No. 4 horizontal plate is connected, and the No. 6 vertical plate connected with the end of the No. 4 horizontal plate is arranged between the No. 1 flange 44 and the No. 2 flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com