Sludge dewatering method by combining iron-carbon micro-electrolysis and Fenton method

A technology of iron-carbon micro-electrolysis and sludge dewatering, which is applied in the oxidation treatment of sludge, dehydration/drying/concentrated sludge treatment, etc., to achieve the effects of reducing dosage, improving dehydration performance, and improving the efficiency of micro-electrolysis reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Example 1

[0040] (1) Pretreatment of activated carbon: soak the activated carbon in the sludge sample for 24 hours to reach the adsorption saturation state, and then air-dry the activated carbon naturally at room temperature for use;

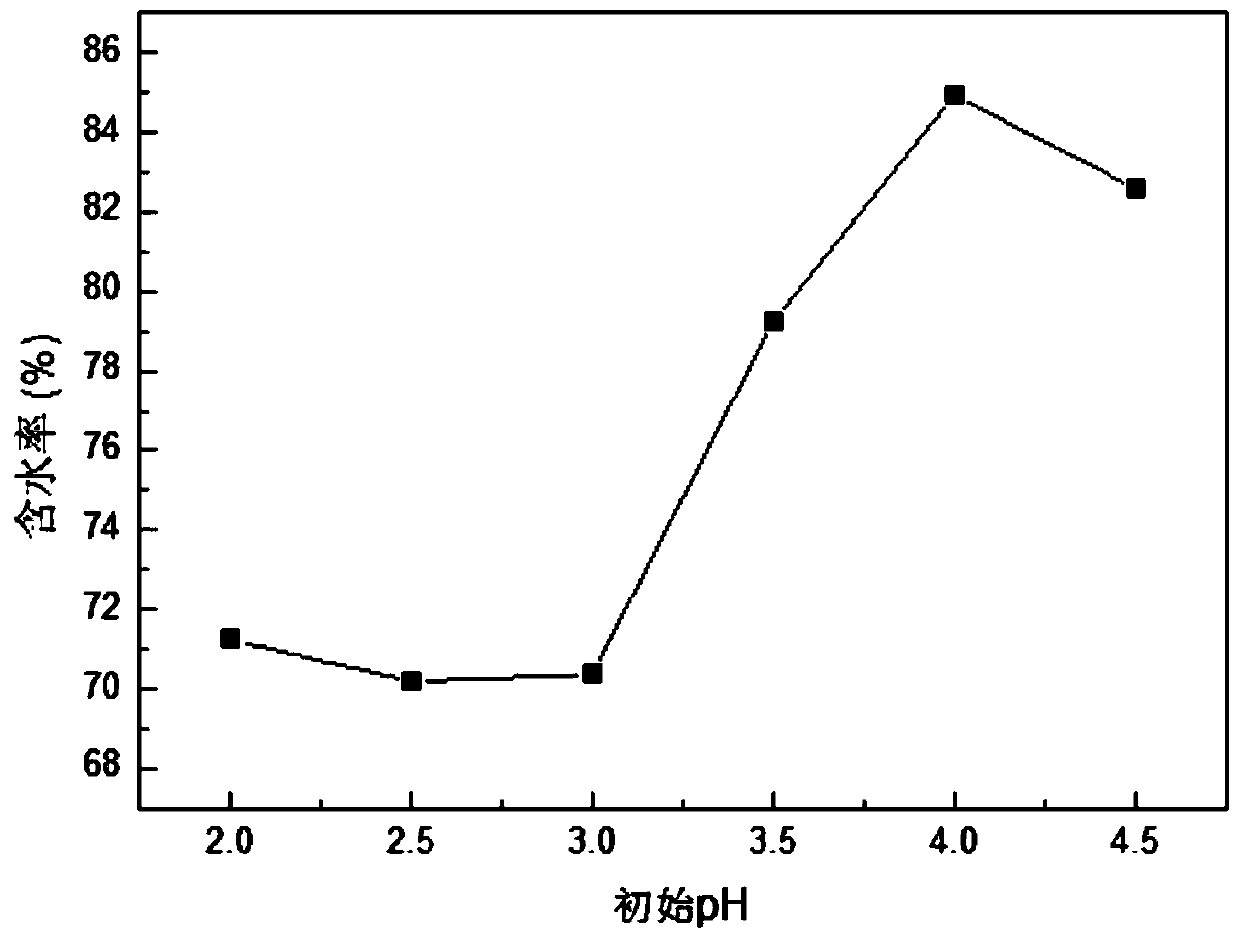

[0041] (2) Take 200 mL of sludge and place it in a beaker, use 10% dilute sulfuric acid and 10% dilute sodium hydroxide to adjust the pH to 2, 2.5, 3, 3.5, 4, 4.5, respectively.

[0042] (3) Add iron powder and activated carbon to the sludge treated in step (2) above. Based on the sludge addition amount, the iron powder addition amount is 4g / L, and the Fe / C mass ratio is controlled to 1:1. The aeration rate is 1.5L / min, and the iron-carbon micro-electrolysis reaction is carried out for 30 minutes.

[0043] (4) Measure the water content of the sludge after the treatment in the above step (3), in order to explore the effect of the pH value of the iron powder on the dewatering performance of the sludge when the iron-carbon micro-electrolysis is pe...

Example Embodiment

[0045] Example 2

[0046] (1) Pretreatment of activated carbon: soak the activated carbon in the sludge sample for 24 hours to reach the adsorption saturation state, and then air-dry the activated carbon naturally at room temperature for use;

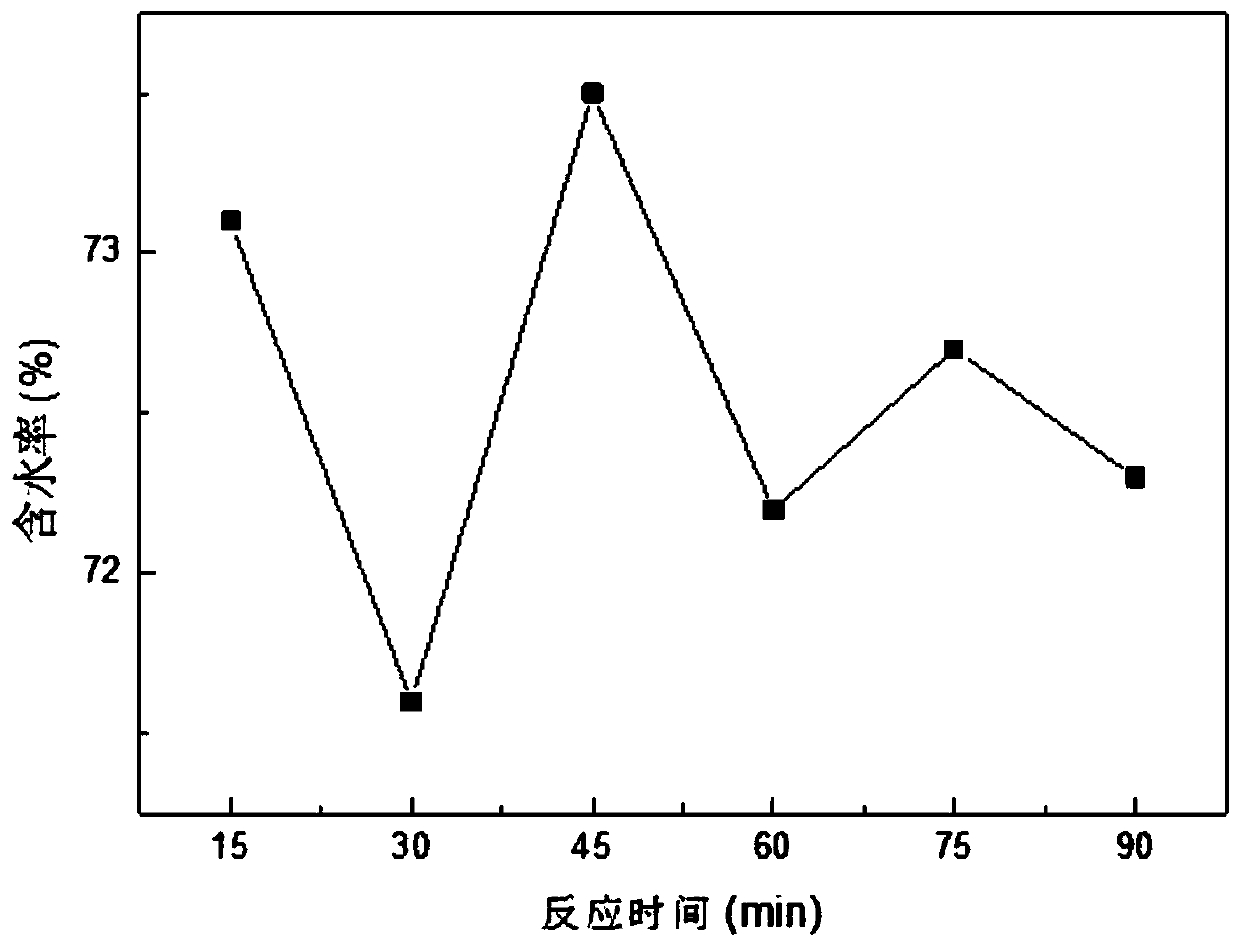

[0047] (2) Take 200 mL of sludge and place it in a beaker, and adjust the pH to 3 with 10% dilute sulfuric acid and 10% dilute sodium hydroxide.

[0048] (3) Add iron powder and activated carbon to the sludge treated in step (2) above, based on the amount of sludge added, the amount of iron powder added is 4g / L, and the Fe / C mass ratio is controlled to 1:1 , Respectively control the reaction time to 15min, 30min, 45min, 60min, 75min, 90min, and the aeration rate to 1.5L / min.

[0049] (4) Measure the water content of the sludge after treatment in the above step (3), in order to explore the effect of the reaction time on the degree of sludge cracking and the sludge dewatering performance in the single iron-carbon microelectrolysis.

[0050] by fi...

Example Embodiment

[0051] Example 3

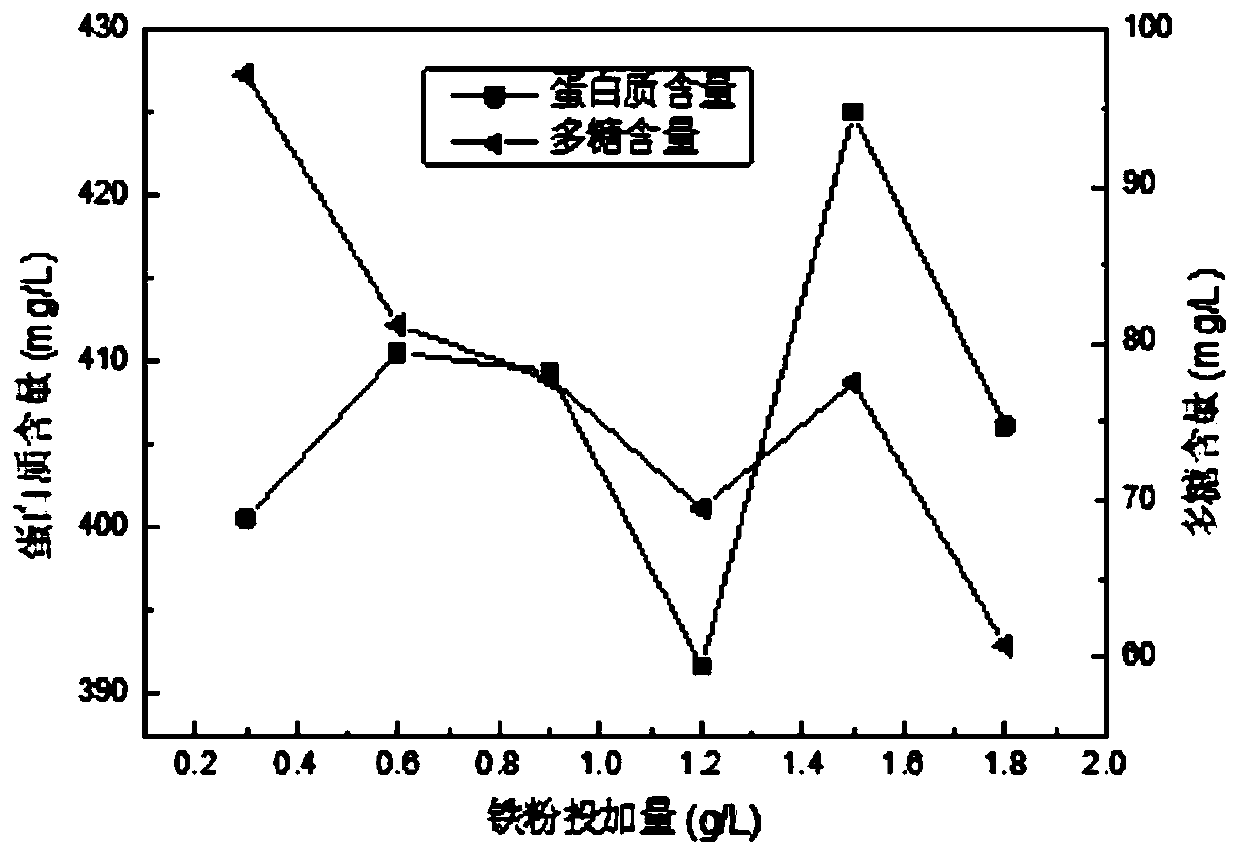

[0052] (1) Pretreatment of activated carbon: soak the activated carbon in the sludge sample for 24 hours to reach the adsorption saturation state, and then air-dry the activated carbon naturally at room temperature for use.

[0053] (2) The sludge was refrigerated at 4°C, and then naturally settled for 24 hours. The supernatant was poured to obtain the settled sludge; 200mL of the settled sludge was placed in a beaker, and 10% dilute sulfuric acid and 10 % Dilute sodium hydroxide adjusts the pH to 2.5.

[0054] (3) Add different amounts of iron powder (0.3g / L, 0.6g / L, 0.9g / L, 1.2g / L, 1.5g / L, 1.8g / L) to the sludge treated in step (2) above. L) and activated carbon, in which the mass ratio of Fe / C is 1:1, the aeration rate is 1.5 L / min, and the micro-electrolysis reaction is performed for 30 minutes.

[0055] (4) Add 3.0g / L of H to the above step (3) 2 O 2 , The rotation speed is 300r / min, and the Fenton reaction is performed for 60 minutes.

[0056] (5) Determine the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com