Production method of firework leading yarn

A production method and technology of fireworks and firecrackers, applied in the manufacture of fuses, etc., can solve the problems of lead wire safety hazards, heavy transit and transportation workload, high production costs, etc., achieve drying efficiency and quality improvement, reduce labor load, and reduce safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

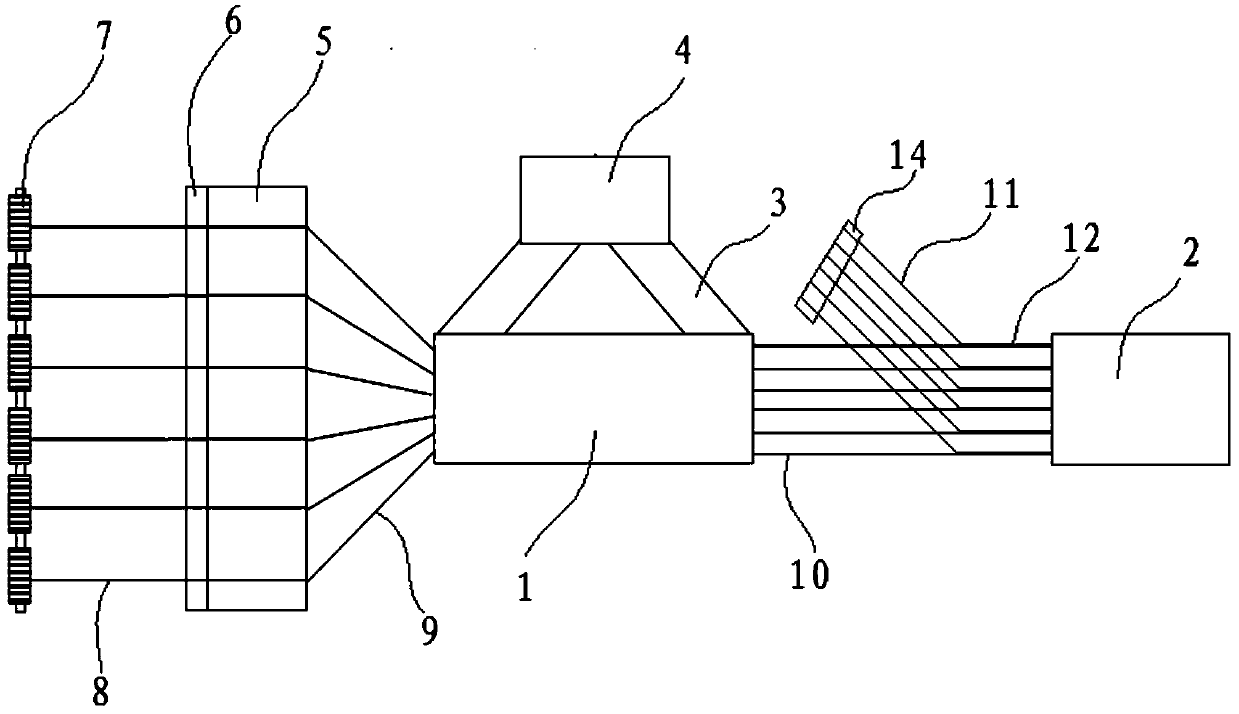

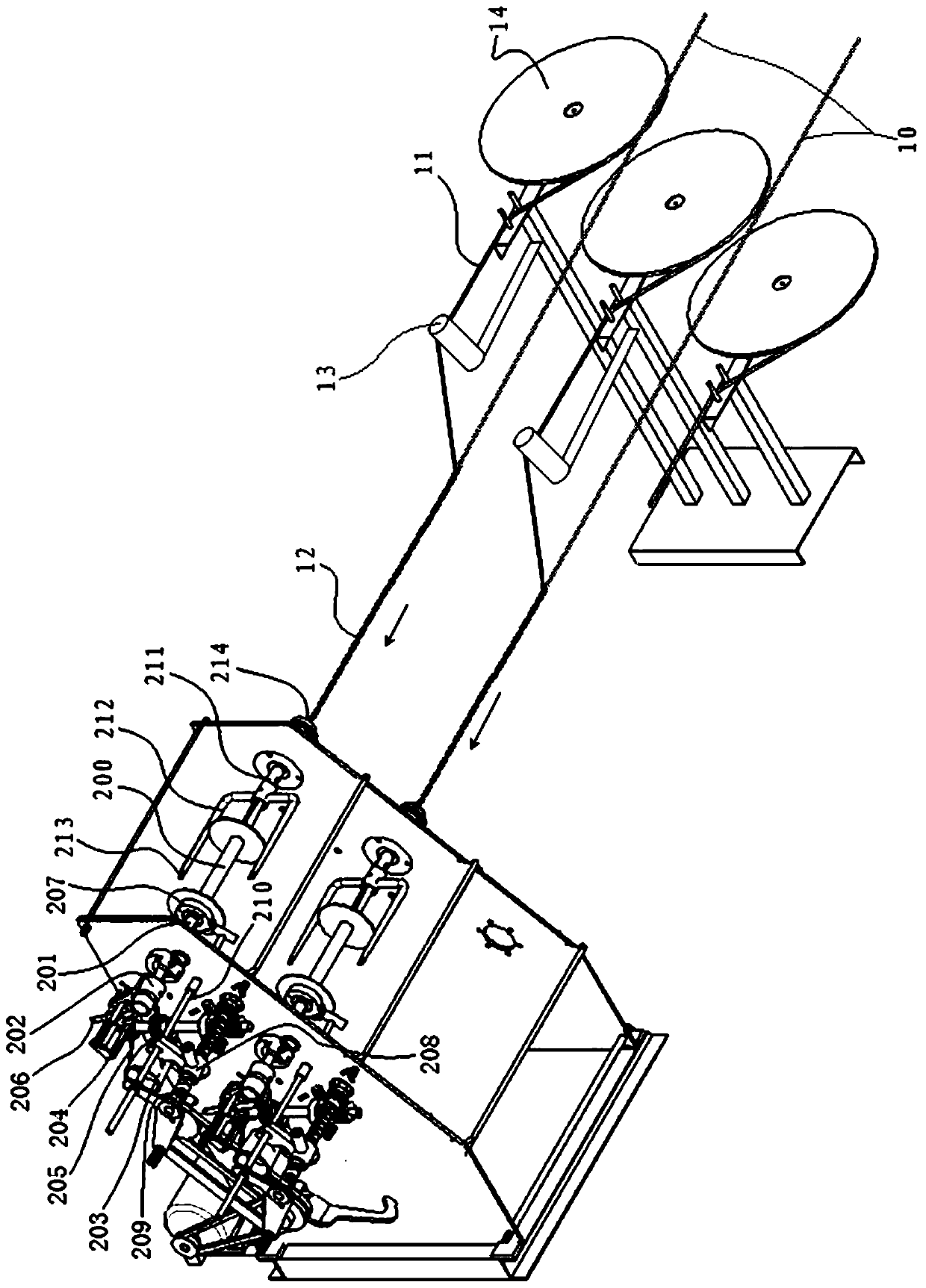

[0024] Referring to the accompanying drawings, which reflect a specific structure of the present invention, in the integrated equipment for making and drying fireworks yarn guides, the yarn 8 drawn by the yarn unwinding mechanism 7 passes through the broken thread detection mechanism 6, the slurry sticking Attached mechanism 5, drying chamber 1, and lead forming mechanism 2 are processed into finished leads. In this process, the traction power of yarn 8 (or finished leads) comes from the winding mechanism of the finished leads of lead forming mechanism 2 (as in this example Rewinding spool 200):

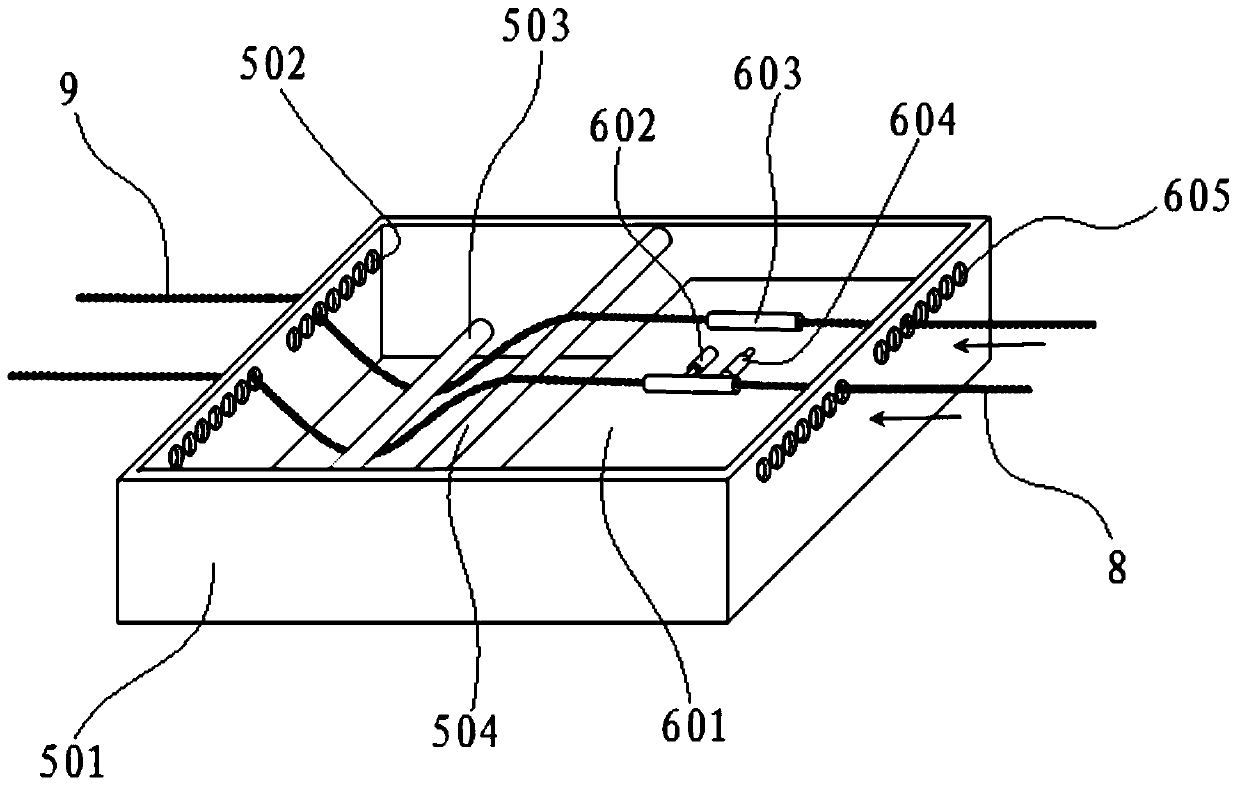

[0025] In this example, the broken thread detection mechanism 6 and the slurry adhesion mechanism 5 are assembled in the slurry box 501, and the two ends of the slurry box 501 are provided with guides, and the guides are composed of a plurality of parallel yarns 8. Holes 502, 605 are formed. The yarn 8 is guided by the guide rollers 503, 504 to pass through the wire holes 502, 605 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com