Scraping white ink for instant lottery ticket and preparation method of scraping white ink

An ink and whitening technology, applied in the field of printing ink, can solve the problems of poor roll-off and poor scratch-off performance, and achieve the effects of easy film formation, good film formation and uniform particle distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

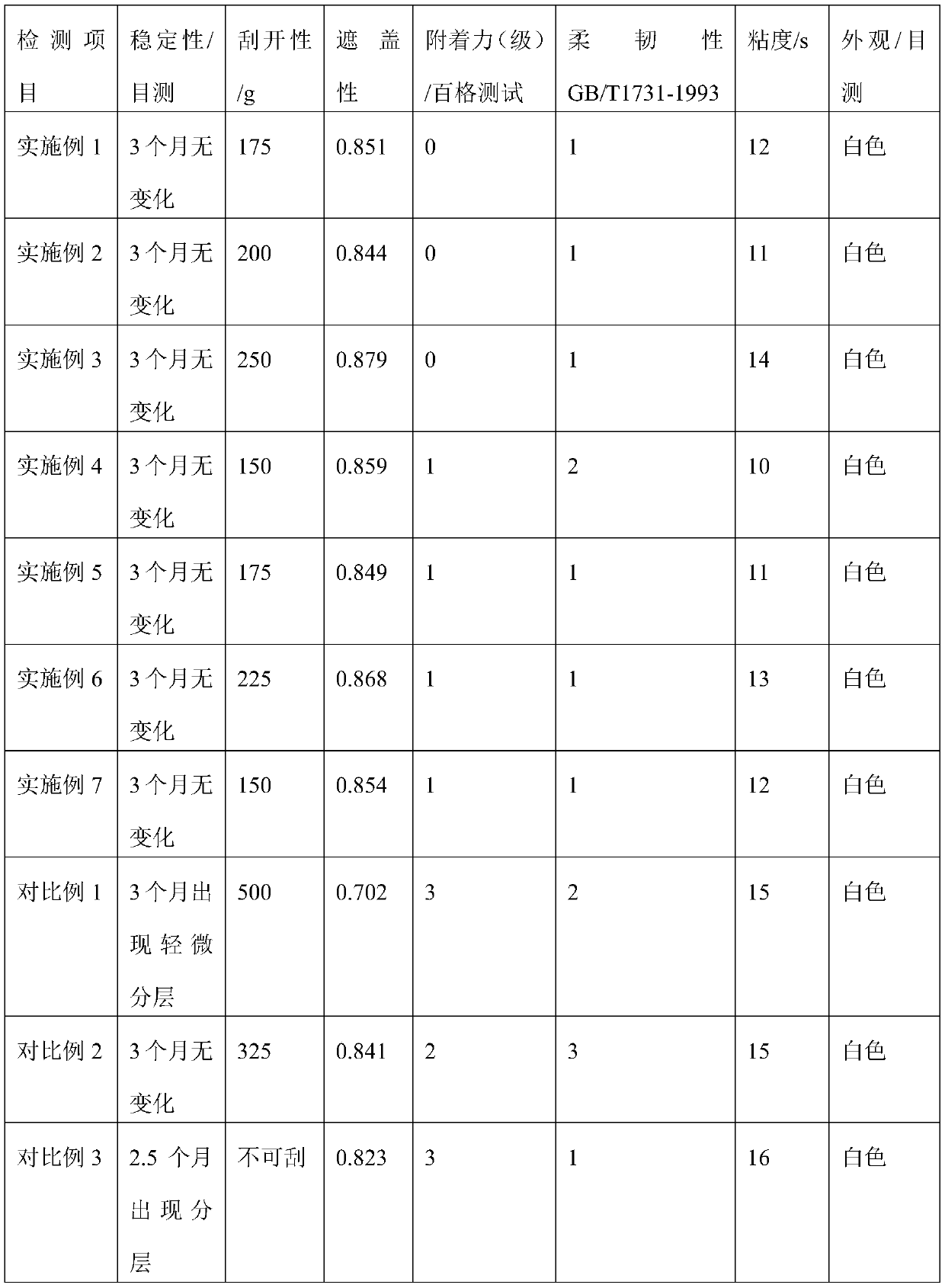

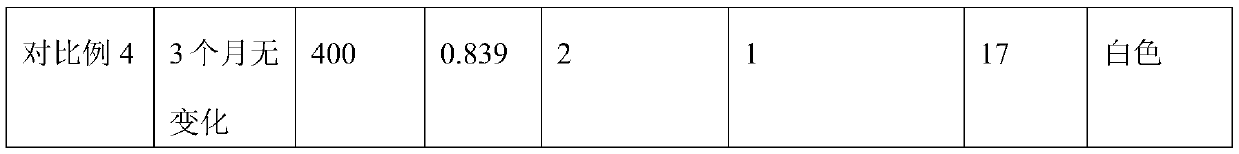

Examples

Embodiment 1

[0025] Components:

[0026] 15g modified acrylic resin, 40g titanium dioxide, 2g glycerol, 1.5g dispersant, 12g acrylic resin, 6g hydrogenated rosin methyl ester, 2.5g slip agent and 21g water.

[0027] Among them, the modified acrylic resin has a molecular weight of 12000Da and a solid content of 35±1%; titanium dioxide, DuPont R706, particle size 10μm; dispersant Nopco SN-Dispersant SN-5027; acrylic resin Neocryl XK-39; hydrogenated rosin methyl ester, Foralyn 5020F; slip agent DC-51.

[0028] preparation:

[0029] 1) Stir the titanium dioxide, dispersant and water at 30°C and 600r / min evenly to obtain the first material;

[0030] 2) Stir and mix the first material with modified acrylic resin, acrylic resin, hydrogenated rosin methyl ester, glycerol and slip agent to obtain the product.

Embodiment 2

[0032] Components:

[0033] 10g modified acrylic resin, 35g titanium dioxide, 1.5g glycerol, 0.5g dispersant, 16g acrylic resin, 8g hydrogenated rosin methyl ester, 3.5g slip agent and 25.5g water.

[0034] Among them, the modified acrylic resin has a molecular weight of 8000Da and a solid content of 35±1%; titanium dioxide, DuPont R706, particle size 5μm; dispersant Nopco SN-Dispersant SN-5027; acrylic resin Neocryl XK-39; hydrogenated rosin methyl ester, Foralyn 5020F; slip agent DC-51.

[0035] preparation:

[0036] 1) Stir the titanium dioxide, dispersant and water at 40°C and 600r / min evenly to obtain the first material;

[0037] 2) Stir and mix the first material with modified acrylic resin, acrylic resin, hydrogenated rosin methyl ester, glycerol and slip agent to obtain the product.

Embodiment 3

[0039] Components:

[0040] 18g modified acrylic resin, 45g titanium dioxide, 2g glycerol, 3.5g dispersant, 6g acrylic resin, 4g hydrogenated rosin methyl ester, 2.5g slip agent and 19g water.

[0041] Among them, the modified acrylic resin has a molecular weight of 15000Da and a solid content of 35±1%; titanium dioxide, DuPont R706, particle size 8μm; dispersant Nopco SN-Dispersant SN-5027; acrylic resin Neocryl XK-39; hydrogenated rosin methyl ester, Foralyn 5020F; slip agent DC-51.

[0042] preparation:

[0043] 1) Stir the titanium dioxide, dispersant and water at 20°C and 800r / min evenly to obtain the first material;

[0044] 2) Stir and mix the first material with modified acrylic resin, acrylic resin, hydrogenated rosin methyl ester, glycerol and slip agent to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com