Air compressor lubricating oil composition with strong oxidation resistance

A lubricating oil composition and anti-oxidative technology, which are applied in the field of lubricating oil to achieve the effects of enhancing anti-oxidation performance, prolonging service life and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

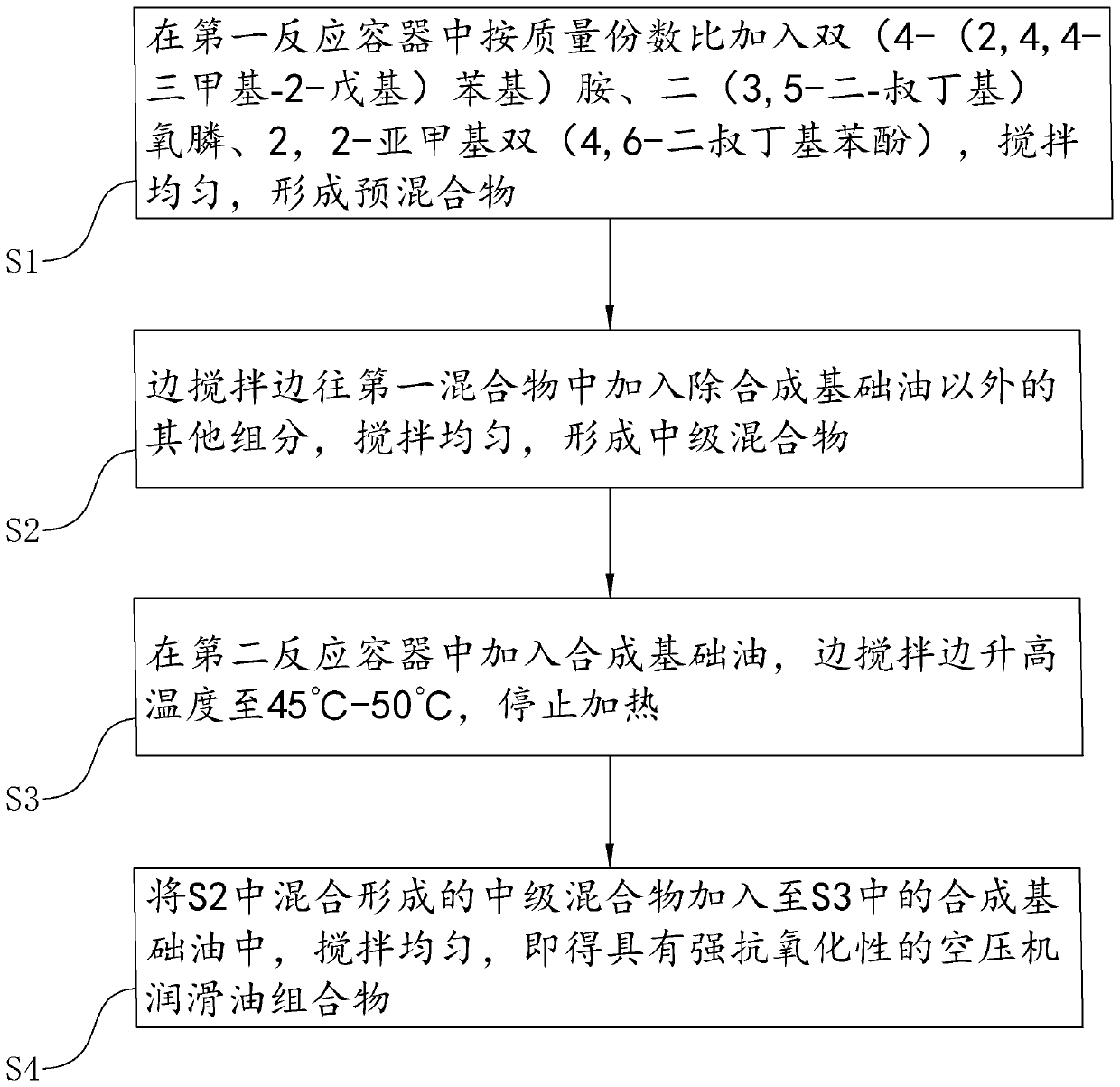

Method used

Image

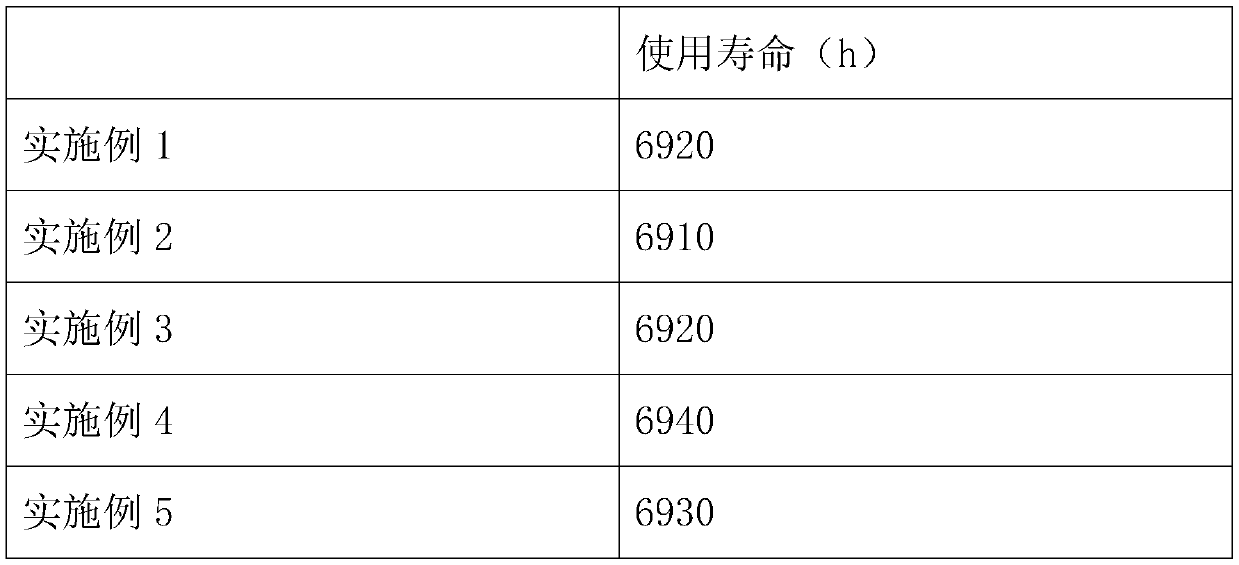

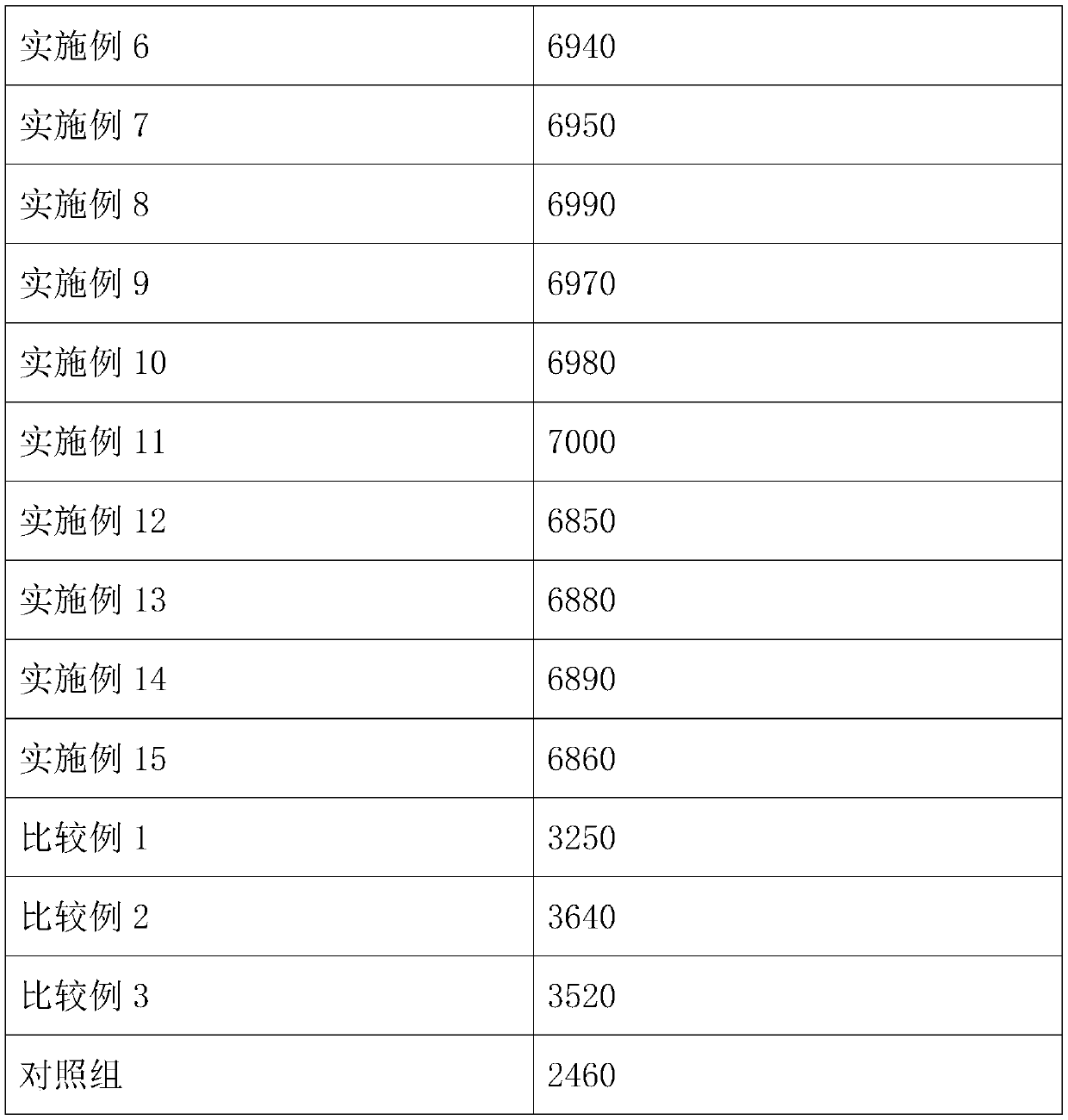

Examples

Embodiment 1

[0061] An air compressor lubricating oil composition with strong oxidation resistance, comprising the following components:

[0062] Synthetic base oil 90kg; demulsifier 0.03kg; antiwear agent 0.4kg; bis(4-(2,4,4-trimethyl-2-pentyl)phenyl)amine 2kg; bis(3,5-di- tert-butyl)phosphine oxide 1kg; 2,2-methylenebis(4,6-di-tert-butylphenol) 2kg.

[0063] In this embodiment, the demulsifier is SP-169 manufactured by Beijing Datian Fengtuo Chemical Technology Co., Ltd.

[0064] The preparation method of the air compressor lubricating oil composition with strong oxidation resistance is as follows:

[0065] S1. Add 2kg of bis(4-(2,4,4-trimethyl-2-pentyl)phenyl)amine and 1kg of bis(3,5-di-tert-butyl)phosphine oxide into the first stirred tank , 2,2-methylene bis(4,6-di-tert-butylphenol) 2kg, stirred evenly to form a premix;

[0066] S2. Add 0.03 kg of demulsifier and 0.4 kg of anti-wear agent to the first mixture while stirring, and stir evenly to form an intermediate mixture;

[0067...

Embodiment 2

[0070] An air compressor lubricating oil composition with strong oxidation resistance, comprising the following components:

[0071] Synthetic base oil 92.5kg; demulsifier 0.01kg; antiwear agent 0.5kg; bis(4-(2,4,4-trimethyl-2-pentyl)phenyl)amine 1.5kg; bis(3,5- Di-tert-butyl)phosphine oxide 0.5kg; 2,2-methylenebis(4,6-di-tert-butylphenol) 1.75kg.

[0072] In this embodiment, the demulsifier is SP-169 manufactured by Beijing Datian Fengtuo Chemical Technology Co., Ltd.

[0073] The preparation method of the air compressor lubricating oil composition with strong oxidation resistance is as follows:

[0074] S1. Add 1.5 kg of bis(4-(2,4,4-trimethyl-2-pentyl)phenyl)amine and bis(3,5-di-tert-butyl)phosphine oxide into the first stirred tank 0.5kg, 2,2-methylenebis(4,6-di-tert-butylphenol) 1.75kg, stir well to form a premix;

[0075] S2. Add 0.01 kg of demulsifier and 0.5 kg of anti-wear agent to the first mixture while stirring, and stir evenly to form an intermediate mixture; ...

Embodiment 3

[0079] An air compressor lubricating oil composition with strong oxidation resistance, comprising the following components:

[0080] Synthetic base oil 95kg; demulsifier 0.02kg; antiwear agent 0.3kg; bis(4-(2,4,4-trimethyl-2-pentyl)phenyl)amine 1kg; bis(3,5-di- tert-butyl)phosphine oxide 0.75kg; 2,2-methylenebis(4,6-di-tert-butylphenol) 1.5kg.

[0081] In this embodiment, the demulsifier is SP-169 manufactured by Beijing Datian Fengtuo Chemical Technology Co., Ltd.

[0082] The preparation method of the air compressor lubricating oil composition with strong oxidation resistance is as follows:

[0083] S1. Add 1 kg of bis(4-(2,4,4-trimethyl-2-pentyl)phenyl)amine and 0.75 kg of bis(3,5-di-tert-butyl)phosphine oxide into the first stirred tank kg, 2,2-methylenebis(4,6-di-tert-butylphenol) 1.5kg, stirred evenly to form a premixture;

[0084] S2. Add 0.02 kg of demulsifier and 0.3 kg of anti-wear agent to the first mixture while stirring, and stir evenly to form an intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com