Continuous aluminum foil oxidation device provided with anode conductive device

A conductive device, aluminum foil technology, applied in the direction of anodic oxidation, electrolytic coating, electrolytic process, etc., can solve problems such as insufficient or too large electrolyte concentration, inability to ensure electrolyte, affect the quality of coating, etc., to avoid harmful gas diffusion, aluminum foil The effect of stable anodizing process and sufficient oxidation of aluminum foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

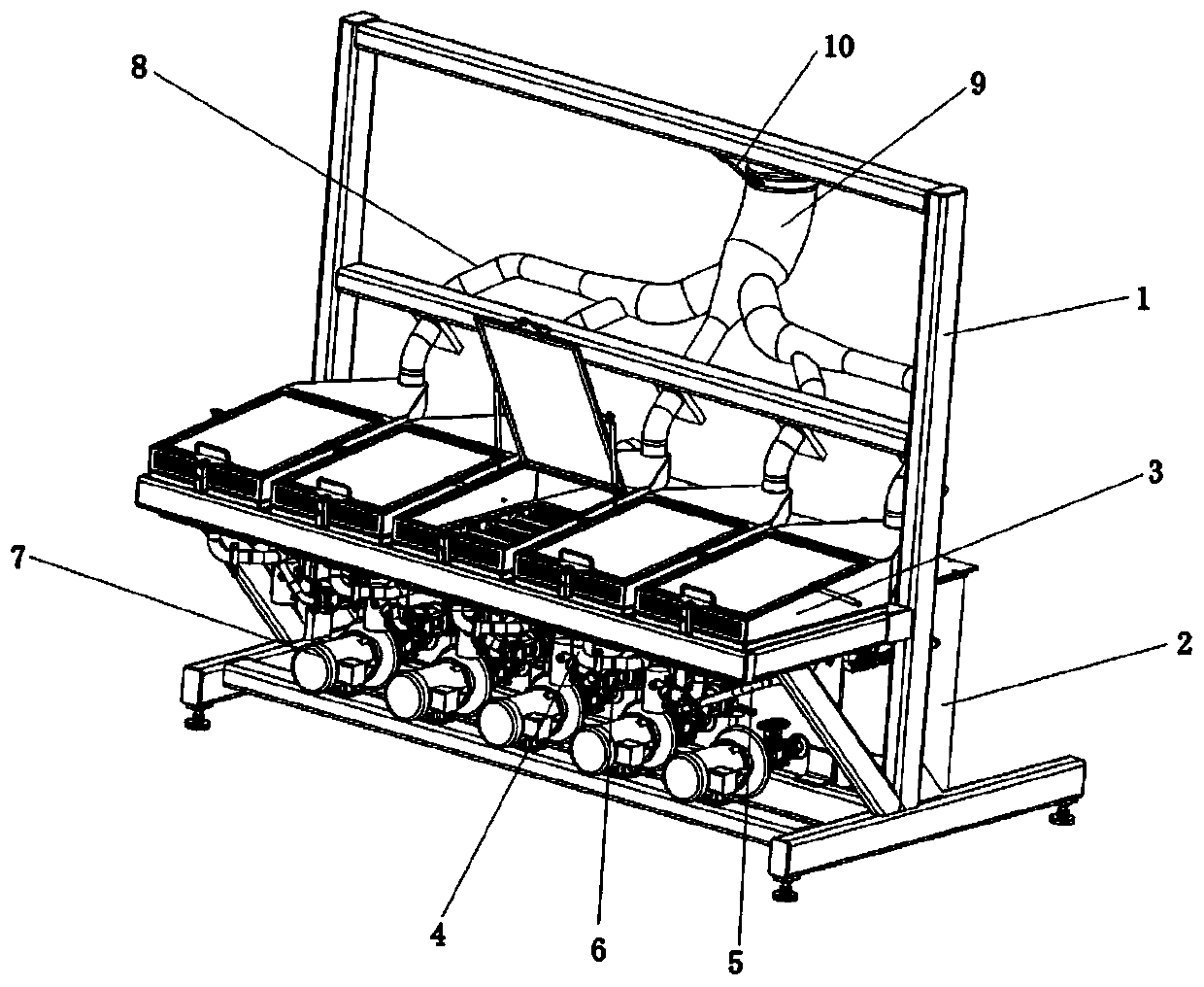

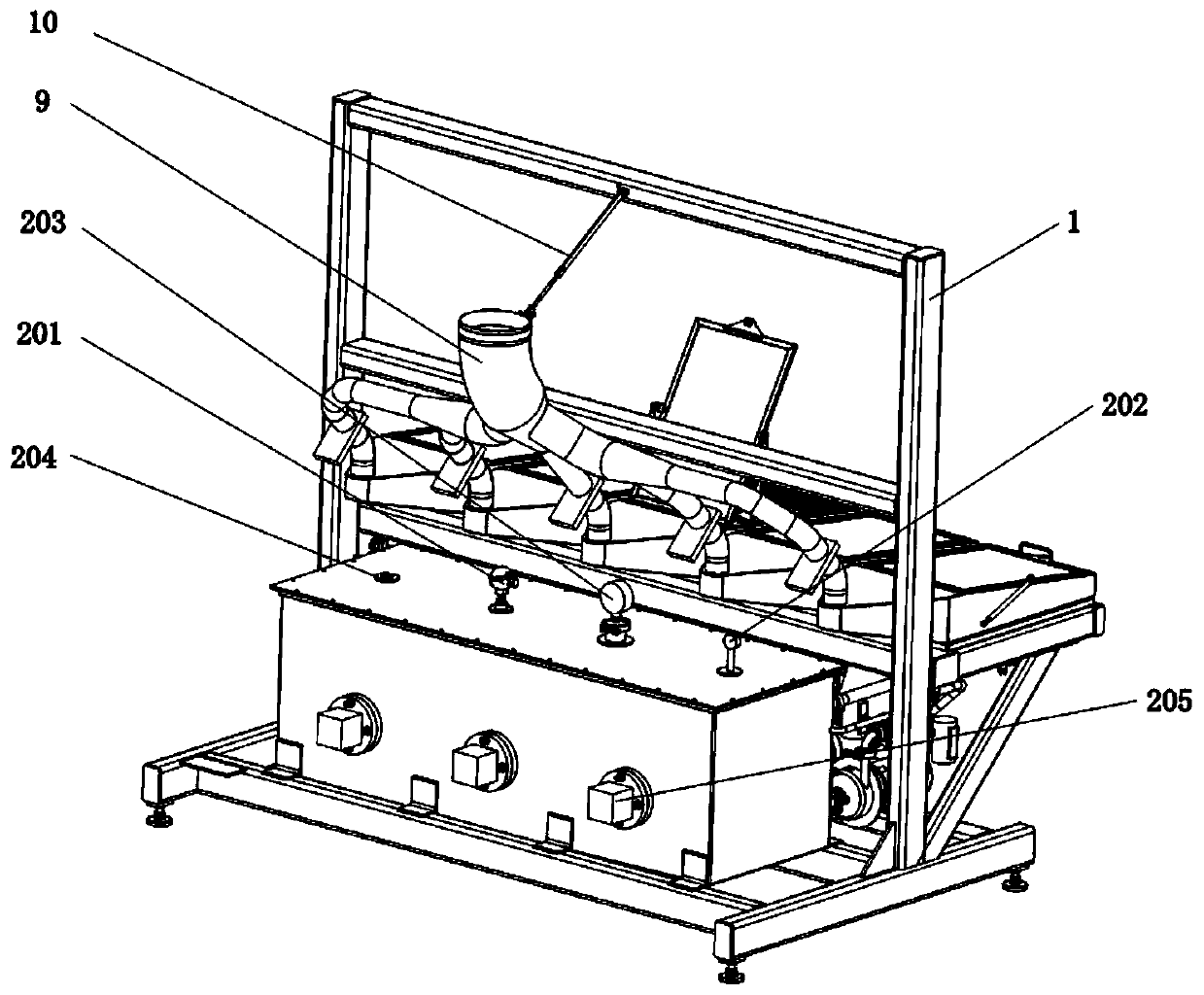

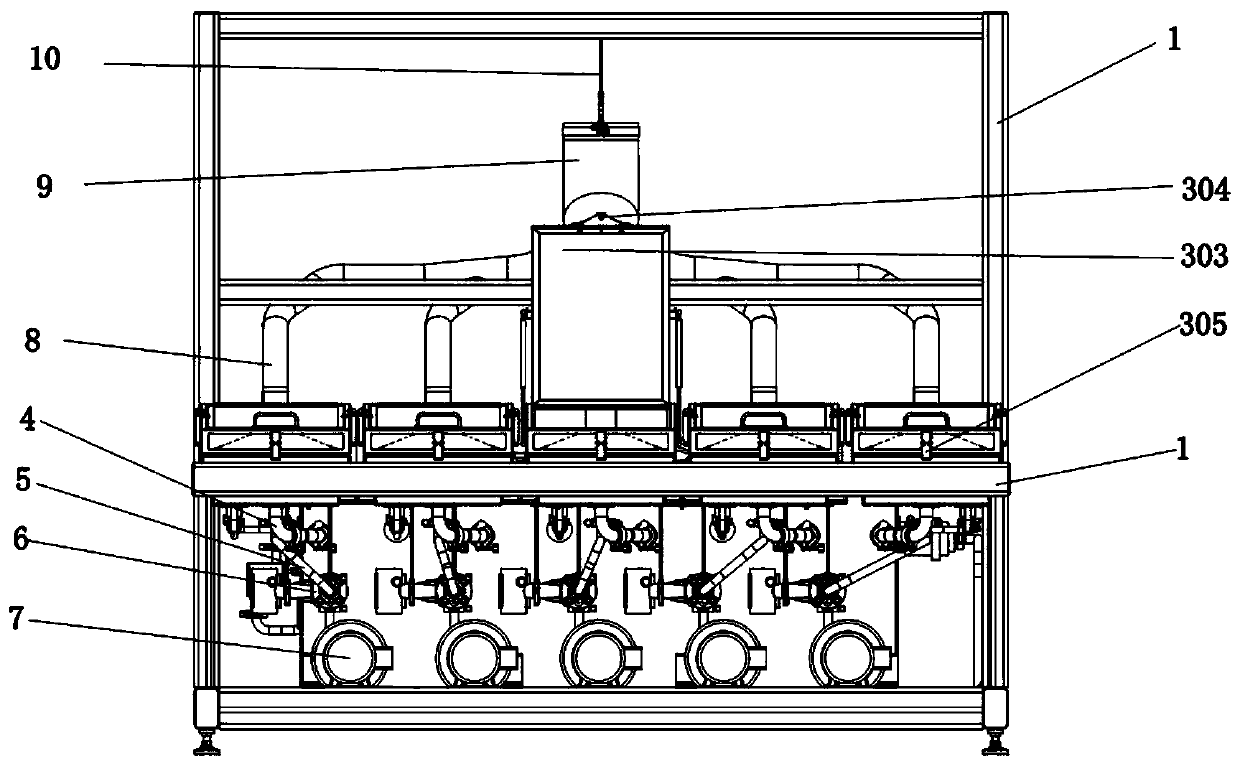

[0034] Depend on Figure 1-6 As shown, a continuous oxidation equipment for aluminum foil with an anode conductive device includes a working frame 1, a liquid storage tank 2 and a number of electrolytic tanks 3. The liquid storage tank 2 and electrolytic tank 3 are made of insulating materials with high corrosion resistance. A workbench 101 is arranged on the frame 1, and a number of electrolytic cells 3 are installed on the workbench 101. The liquid storage tank 2 and each electrolytic cell 3 are respectively filled with an electrolyte with a set concentration, and the electrolyte in the electrolytic cell 3 is soaked with The cathode grid 301 and the anode conductive support 302, the cathode grid 301 is evenly distributed and fixed on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com