Automatic measurement device and measurement method of underground coal mine seam gas content

A technology of coal seam gas and measuring device, applied in the direction of analyzing materials, instruments, etc., can solve the problems of cumbersome process, undulating water surface, long measurement period, etc., and achieve the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

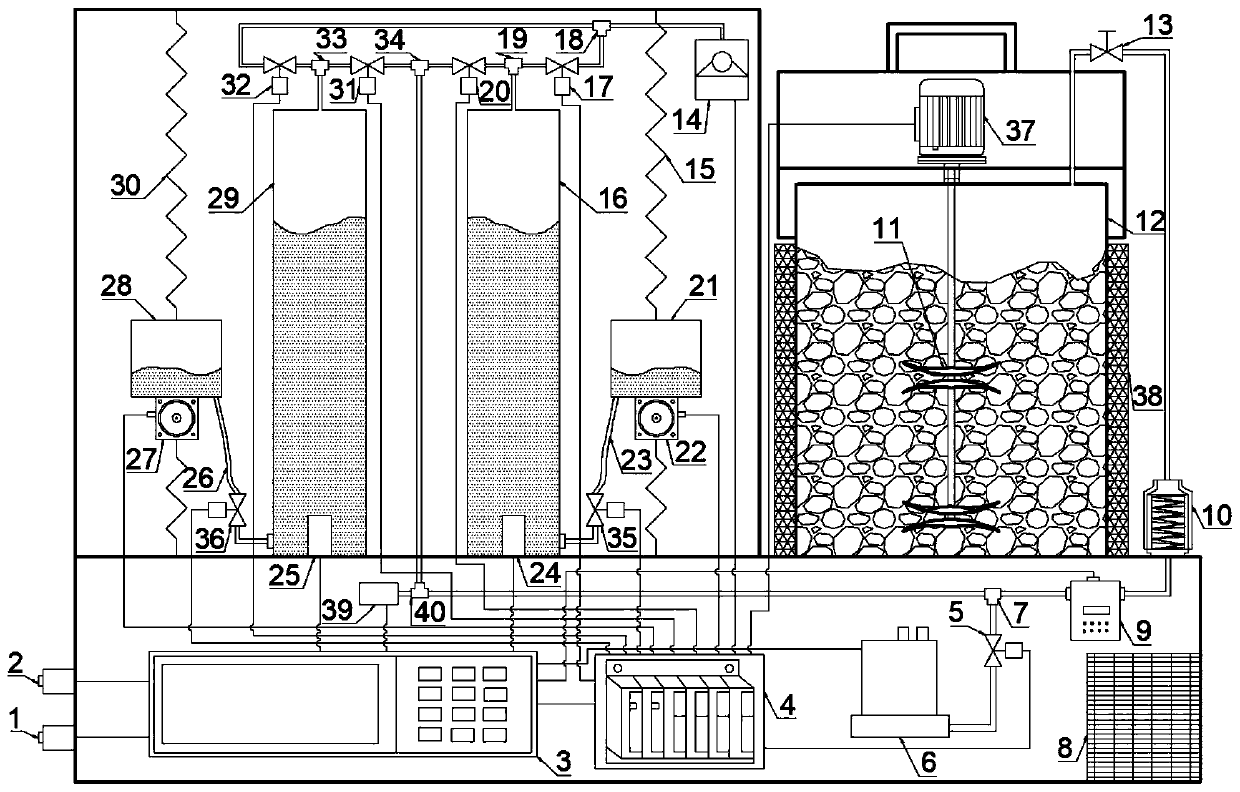

[0078] ① Fill the vector cylinder Ⅰ16 and the measuring cylinder Ⅱ29 with a 1:100 ratio of potassium permanganate and water, turn on the power of the measuring device, and click the start sampling button on the central multi-function processing display at the same time as drilling in the coal mine , after drilling and taking out the cuttings, remove gangue, mudstone and ground burnt parts, weigh them, then quickly put them into the coal sample tank and tighten them, and click the stop sampling button on the central multi-function processing display, the central multi-function The processing display automatically records the time from drilling to loading into the coal sample tank as 10 minutes, and then enters the weighed coal sample mass of 400g in the prompt window;

[0079] ② Degree sensor 1 and gas pressure sensor Ⅰ 2 sense the ambient temperature of 25°C and atmospheric pressure of 0.1MPa in real time, and transmit them to the central multi-function processing display 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com