Nasal cavity implant and application thereof

A technology for implants and nasal cavity, which is applied in the field of medical devices to achieve good meshing ability, high-efficiency treatment effect, and stable release amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

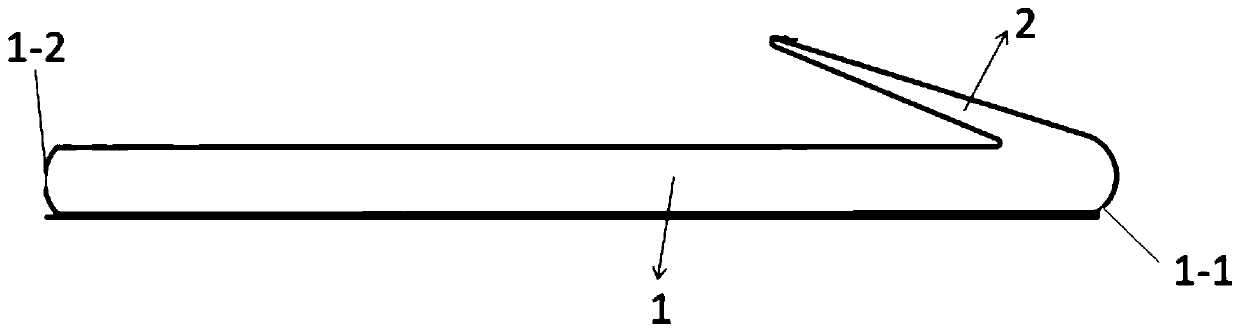

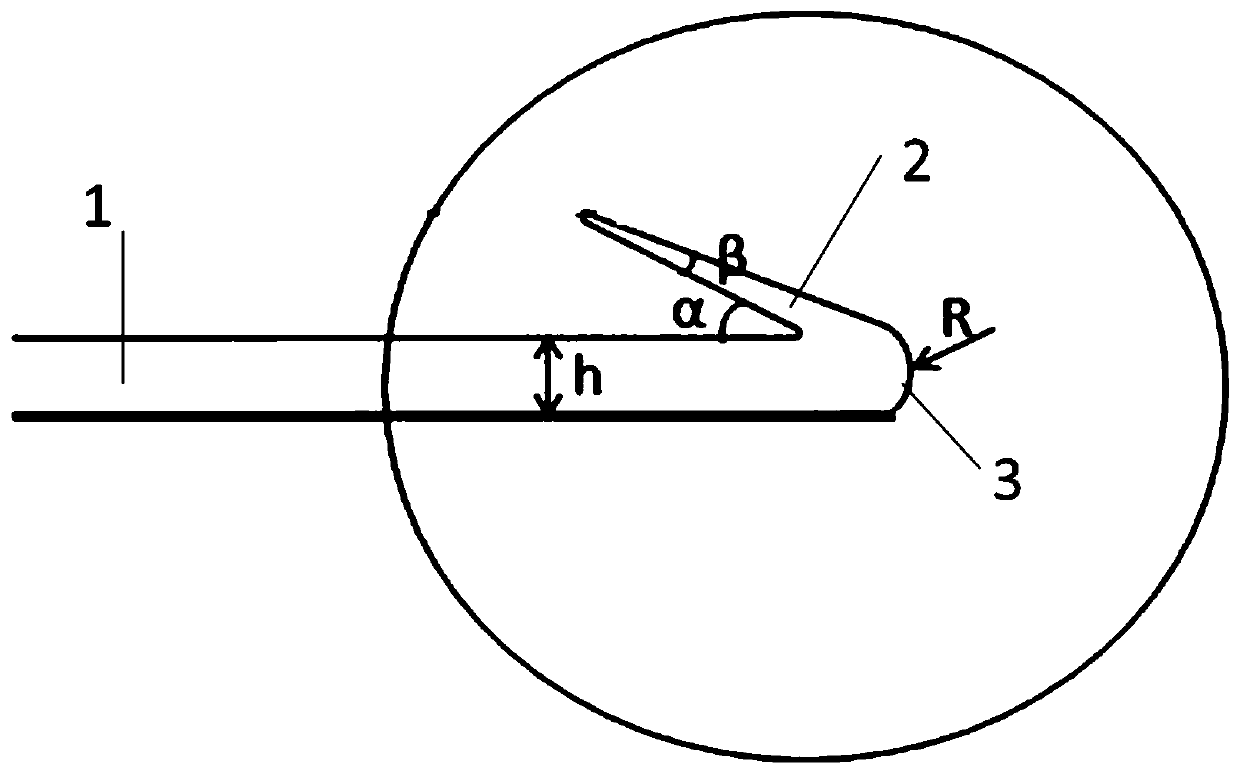

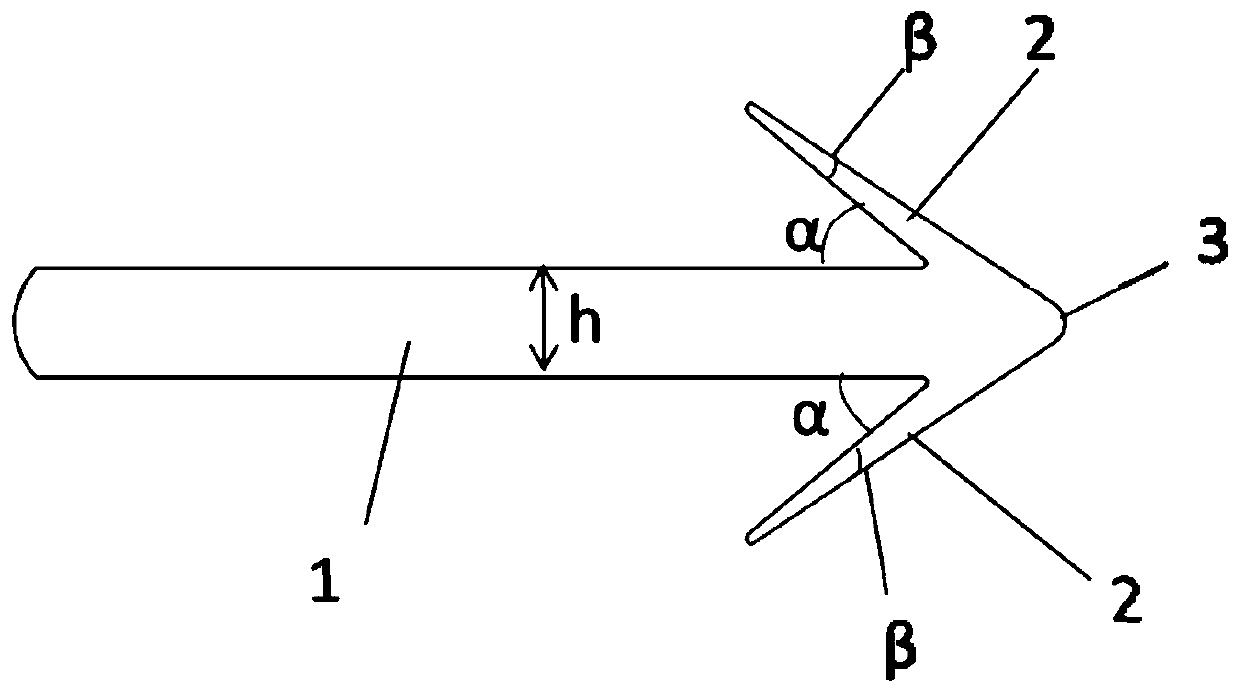

[0087] This embodiment provides an implant, consisting of figure 1 and figure 2It can be seen that the implant includes a main body 1 and an engaging part 2, the main body 1 includes a connecting end 1-1 and a free end 1-2, and the connecting end 1-1 and the engaging part 2 of the main body 1 are away from the surface of the main body 1. The rounded terminals 3 are connected continuously; the main body 1 is in the shape of a cylinder, and the diameter h of the cylinder is 0.5 mm; the shape of the engaging part 2 is conical, and the cone angle of the cone is β, and β is 30°; From the connecting end 1-1 to the free end 1-2 of the main body 1, the angle between the busbar of the engaging part 2 closest to the main body 1 and the outer wall of the main body 1 is α, and α is 50°; the contact surface of the engaging part 2 and the main body 1 The maximum linear distance between any two points of the cylinder is 80% of the diameter of the cylinder, which is 0.4mm; the radius R of t...

Embodiment 2

[0093] This embodiment provides an implant, the implant includes a main body and an engaging part, the main body includes a connecting end and a free end, and the surface of the engaging part away from the main body is continuously connected to the rounded terminal; wherein the shape of the main body is Cylinder, the diameter h of the cylinder is 0.8mm; the shape of the engaging part is conical, the cone angle of the cone is β, and β is 5°; towards the direction from the connecting end to the free end of the main body, the part of the engaging part closest to the main body The angle between the busbar and the outer wall of the main body is α, and α is 20°; the maximum linear distance between any two points on the contact surface of the engaging part and the main body is 50% of the diameter of the cylinder, which is 0.4mm; the connecting part and the main body The radius of the fillet is 50% of the diameter of the cylinder, which is 0.4mm; the number of engaging parts is 1.

[...

Embodiment 3

[0101] This embodiment provides an implant. The implant includes a main body and an engaging part. The main body includes a connection end and a free end. The surface of the engaging part away from the main body is continuously connected to the rounded terminal; wherein the shape of the main body is It is a cylinder, and the diameter h of the cylinder is 0.05mm; the shape of the engaging part is conical, and the cone angle of the cone is β, and β is 50°; towards the direction from the connecting end to the free end of the main body, the engaging part is closest to the main body The angle between the busbar and the outer wall of the main body is α, and α is 70°; the maximum linear distance between any two points on the contact surface of the engaging part and the main body is 100% of the diameter of the cylinder, which is 0.05mm; the engaging part is connected to the main body The radius of the fillet is 2% of the diameter of the cylinder, which is 0.001mm; the number of engagin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com