Nanocarbon material, preparation method thereof, and application of nanocarbon material to fuel cells

A nano-carbon material, nano-carbon technology, applied in nano-carbon, nano-technology, nano-technology and other directions, can solve the problems of high price, restrict the promotion process, scarcity of resources, etc., achieve good electrical conductivity, achieve uniform dispersion, and few structural defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

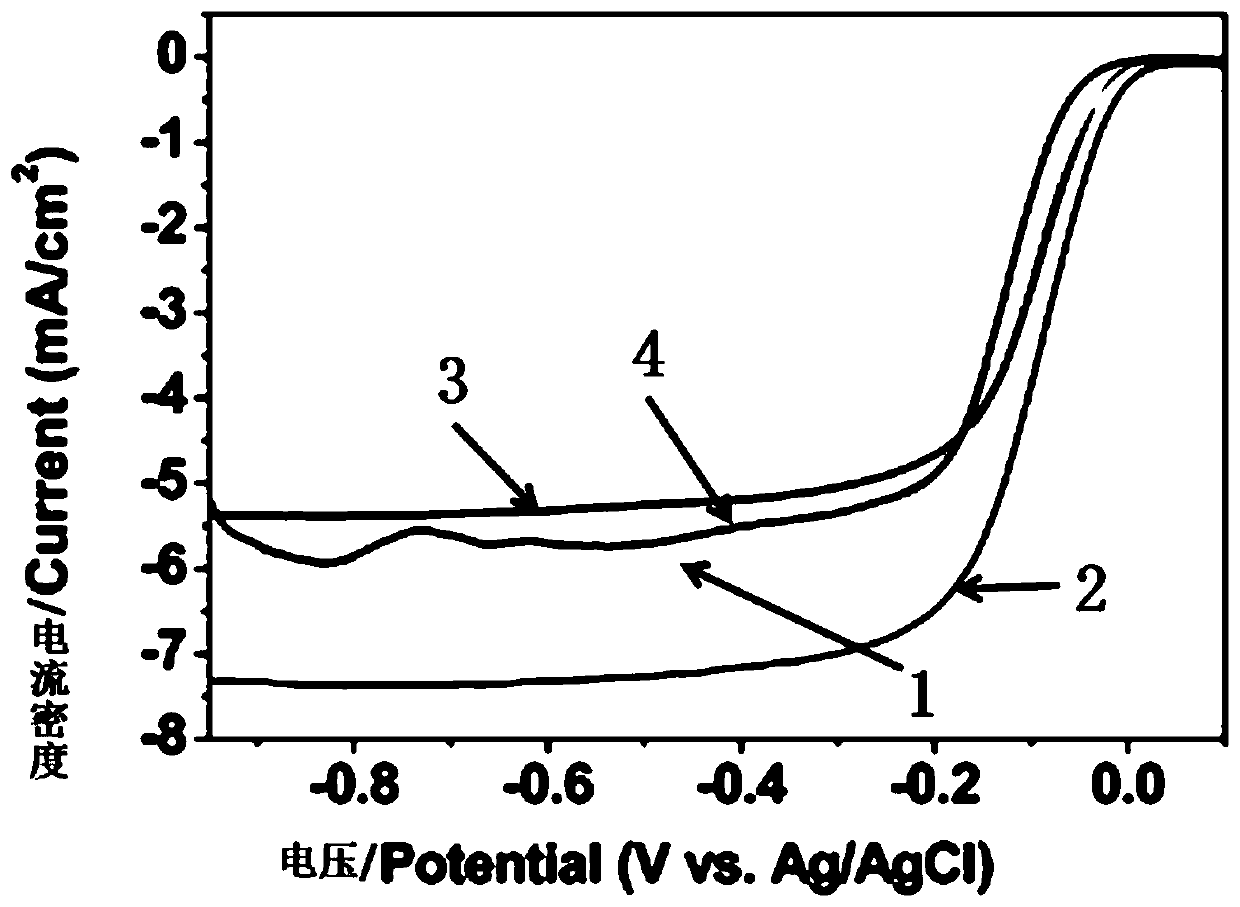

[0091] According to one embodiment of the present application, the preparation method of the non-noble metal oxygen reduction catalyst comprises the following steps:

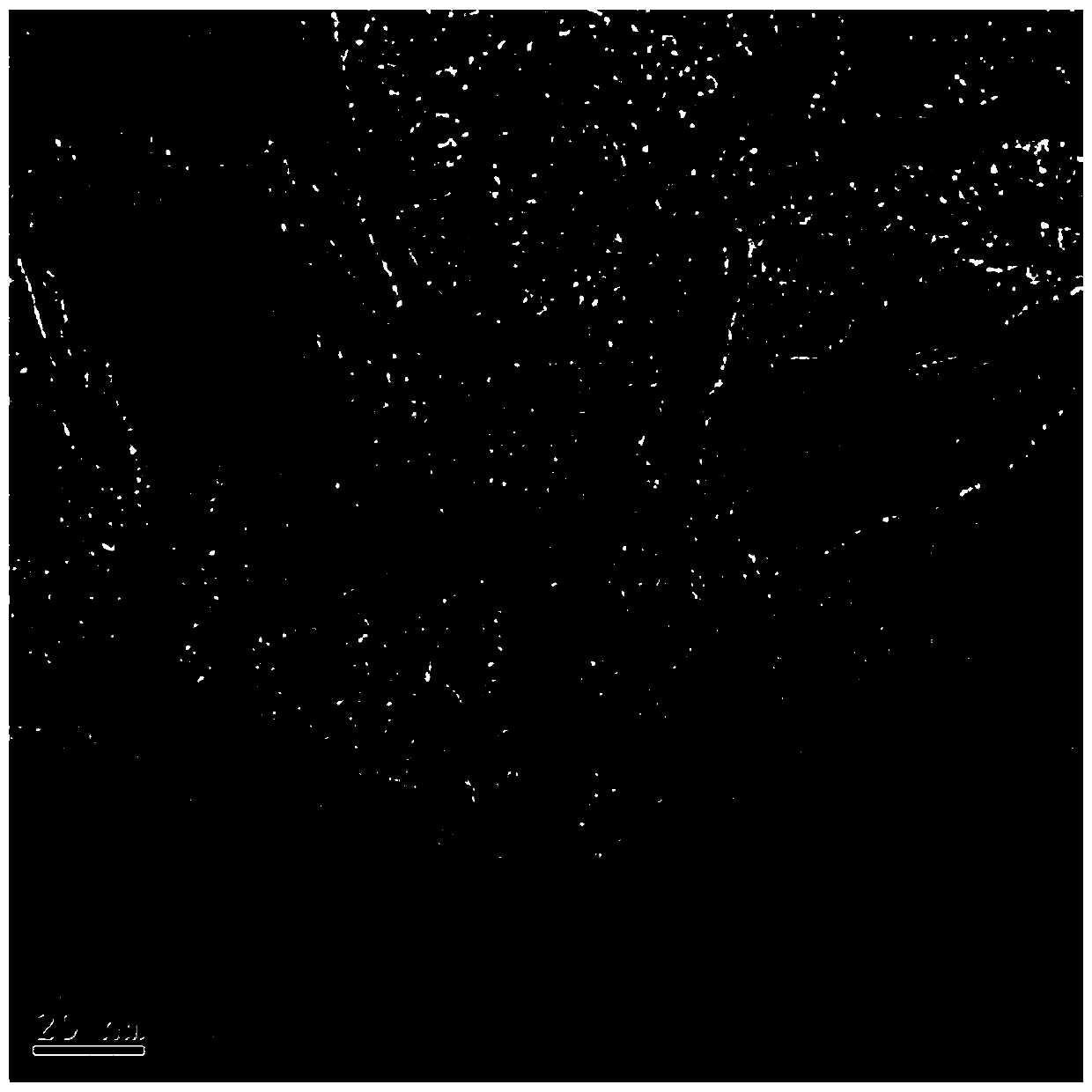

[0092] 1) the heme (C 34 h 32 FeN 4 o 4 ) is dissolved in the alkali solution, and the composite nanocarbon (GH) of the graphene sheet and the carbon nanohorn is evenly dispersed in the above solution to form a uniform dispersion;

[0093] 2) Subjecting the above dispersion to a hydrothermal reaction, the hydrothermal reaction temperature is 160-200°C, and the hydrothermal reaction time is 12-48 hours;

[0094] 3) After the product of the above hydrothermal reaction is filtered, washed and dried, it is placed in a hydrogen atmosphere furnace or an inert atmosphere or a mixture of the two atmospheres for high-temperature annealing treatment, and finally a black solid is obtained, which is the non-precious metal oxygen reduction catalyst.

[0095] The non-noble metal oxygen reduction catalyst is a hierarchical...

Embodiment 1

[0100] 1. The composite nanocarbon (GH) of graphene sheets and carbon nanohorns prepared by direct current arc method: one end of two solid graphite rods with diameters of 8 mm and 6 mm are respectively installed on the positive and negative poles of the direct current arc discharge chamber, and the two graphite rods are kept The shaft centers of the rods are on the same straight line, and their other ends are in contact; then the cavity of the DC arc discharge chamber is filled with air at normal pressure (0.1MPa), and the discharge chamber is kept in a sealed state; then energized at the same time Adjust the DC discharge current at 100A for discharge and arc start. During the discharge process, keep the distance between the ends of the cathode and anode at 1 to 10mm, so that the anode and cathode can continuously start and discharge the arc until the graphite rod of the anode is consumed and stops, and the entire discharge The process takes 10 minutes. The black solid matter...

Embodiment 2

[0111] The difference between this example and Example 1 is that the annealing temperature in step 5 was changed to 750°C and 950°C respectively, and the other conditions were the same, and the obtained samples were marked as GH-Fe-N-750, GH-Fe-N-750, GH-Fe- N-950.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com