Harmonic oscillator structure of laser gyroscope

A laser gyroscope and substructure technology, which is applied to Sagnac effect gyroscopes, gyroscopes/steering sensing devices, measuring devices, etc., can solve the problems of high processing difficulty, high processing accuracy requirements, and high manufacturing costs, and achieves a high level of improvement. Performance and precision, high mechanical sensitivity, elimination of zone-locking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

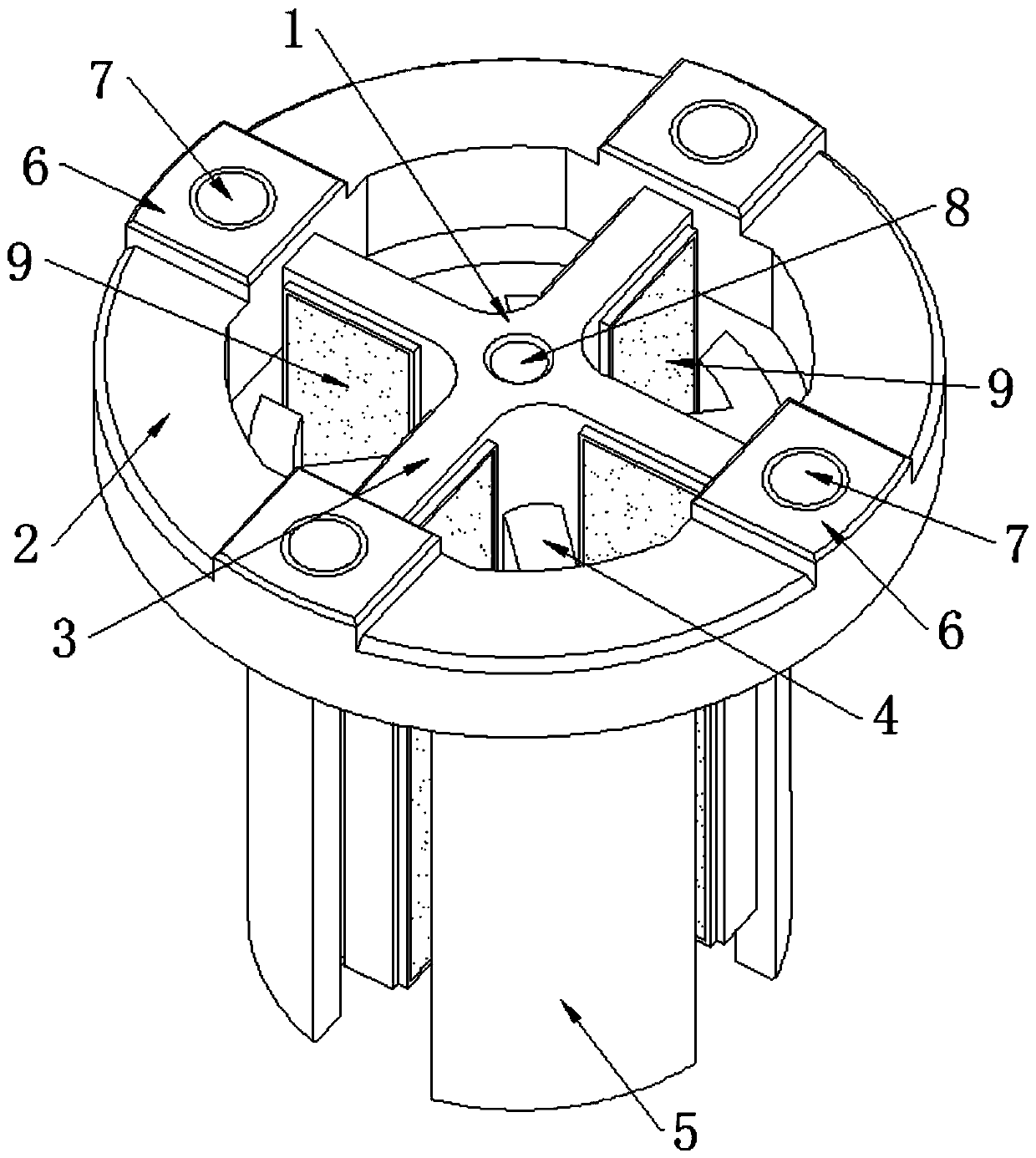

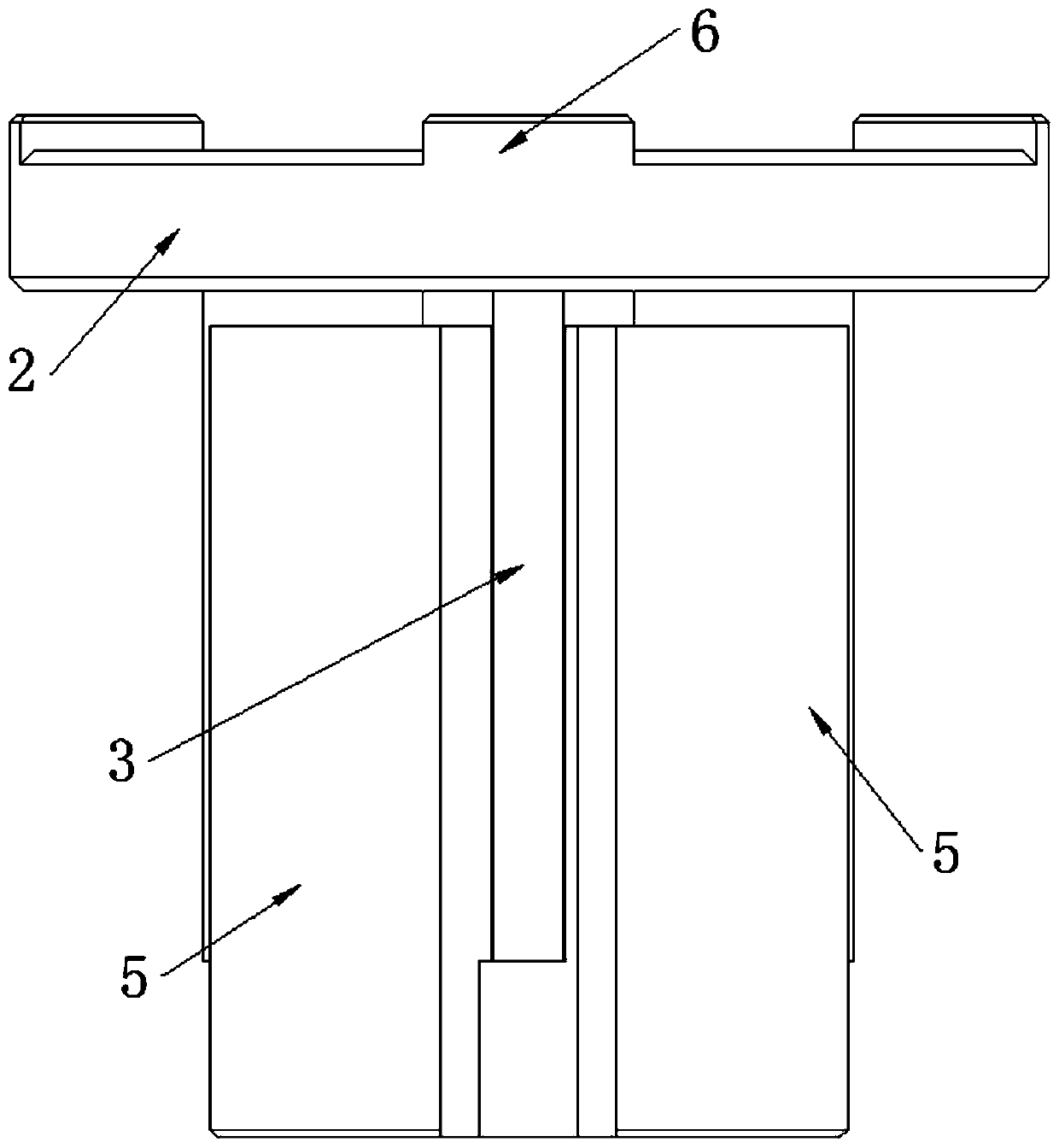

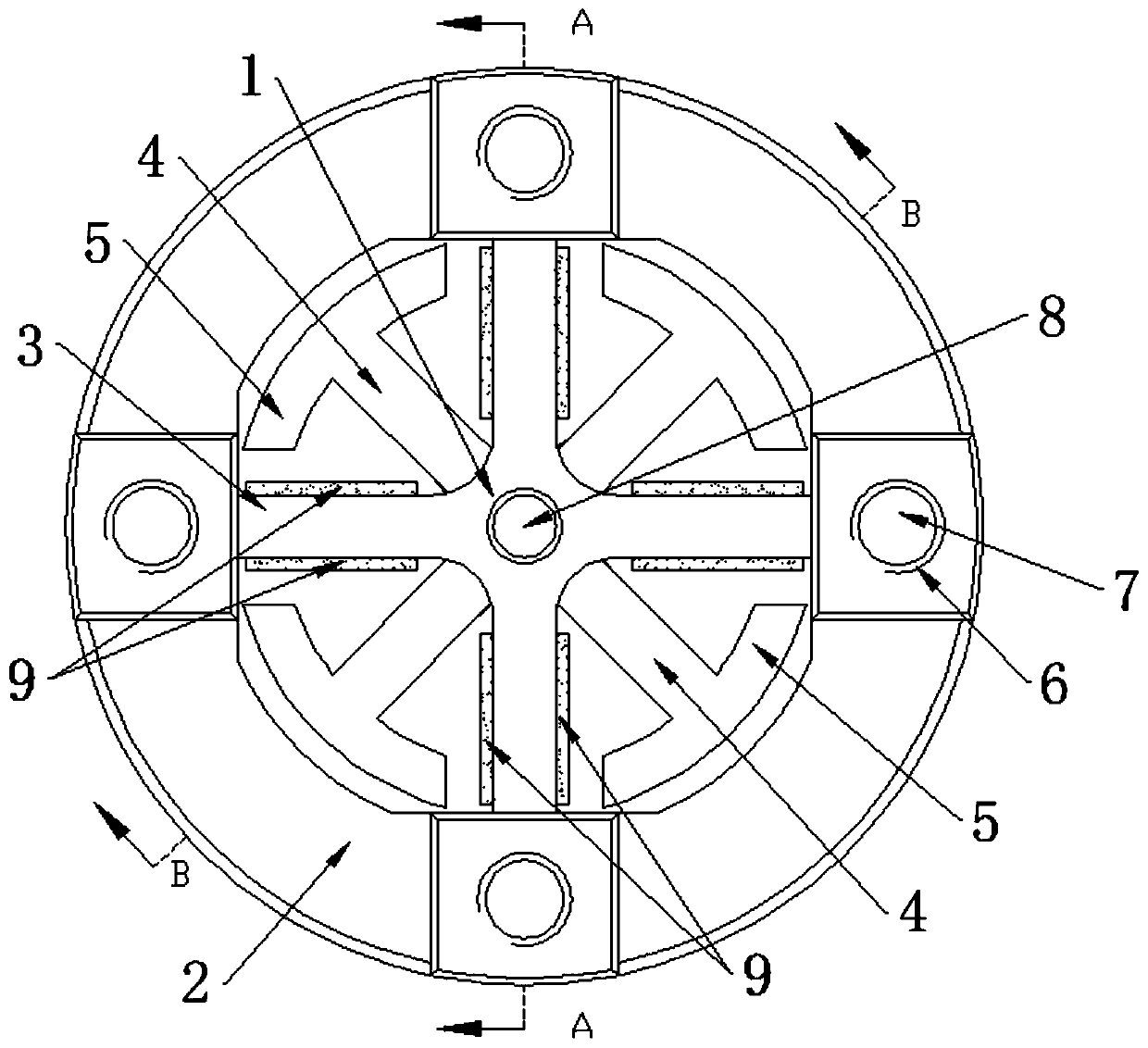

[0026] Such as Figure 1 to Figure 5 As shown, a laser gyro resonator structure includes a central body 1, a resonant ring 2, spokes 3, a vibration transmission beam 4 and a vibration transmission piece 5, and the upper surface of the resonator ring 2 protrudes upwards to form four installation steps 6. The four installation steps 6 are symmetrically distributed, and the center of each installation step 6 is provided with an installation hole 7, and the center of the central body 1 is equipped with a central hole 8, and the resonant ring 2 is sleeved On the outside of the central body 1, the outer wall of the central body 1 is connected to the inner wall of the resonant ring 2 through four spokes 3, and the four spokes 3 are distributed circularly symmetrically around the central hole 8, The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com