Cohesive soil sample preparation device for soil test and use method

A technology of geotechnical testing and cohesive soil, which is applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problems of increasing the difficulty of demoulding operation, failure of soil sample production, etc., to reduce the steps of sealing and wrapping, and reduce the number of samples The effect of interference, avoiding deformation and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

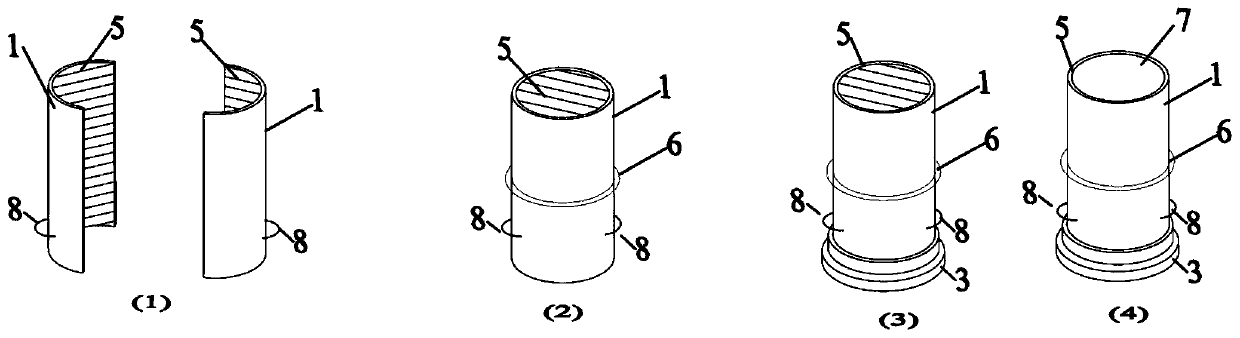

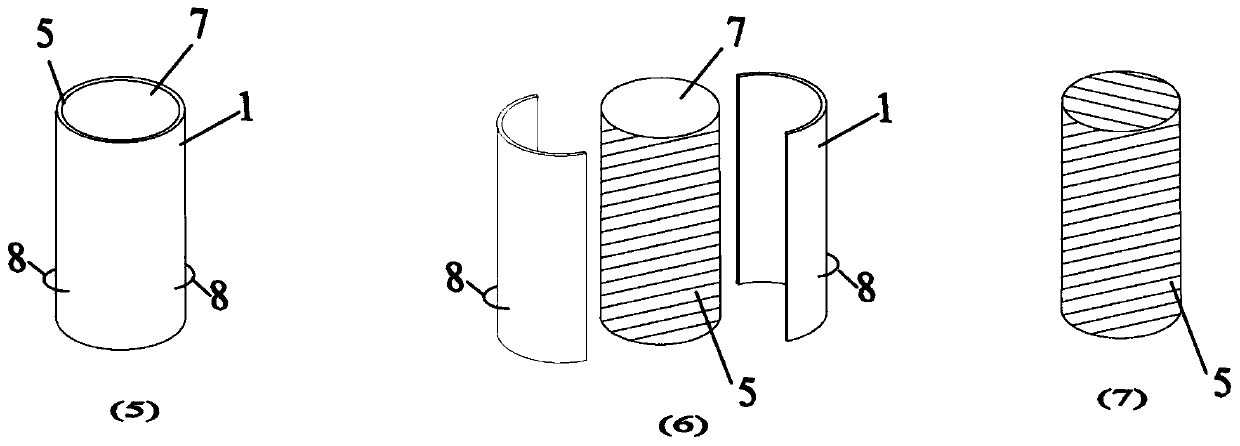

[0016] In order to deepen the understanding of the present invention, the specific embodiments of the present invention will be described in further detail with reference to the accompanying drawings.

[0017] The invention provides a cohesive soil sample preparation device for geotechnical tests and a method of use, especially for the production of standard test pieces of cohesive soil, which solves the problem of soil sample preparation failure due to the sticking of the soil sample to a mold, and also Satisfy the production requirements of non-cohesive rock and soil specimens.

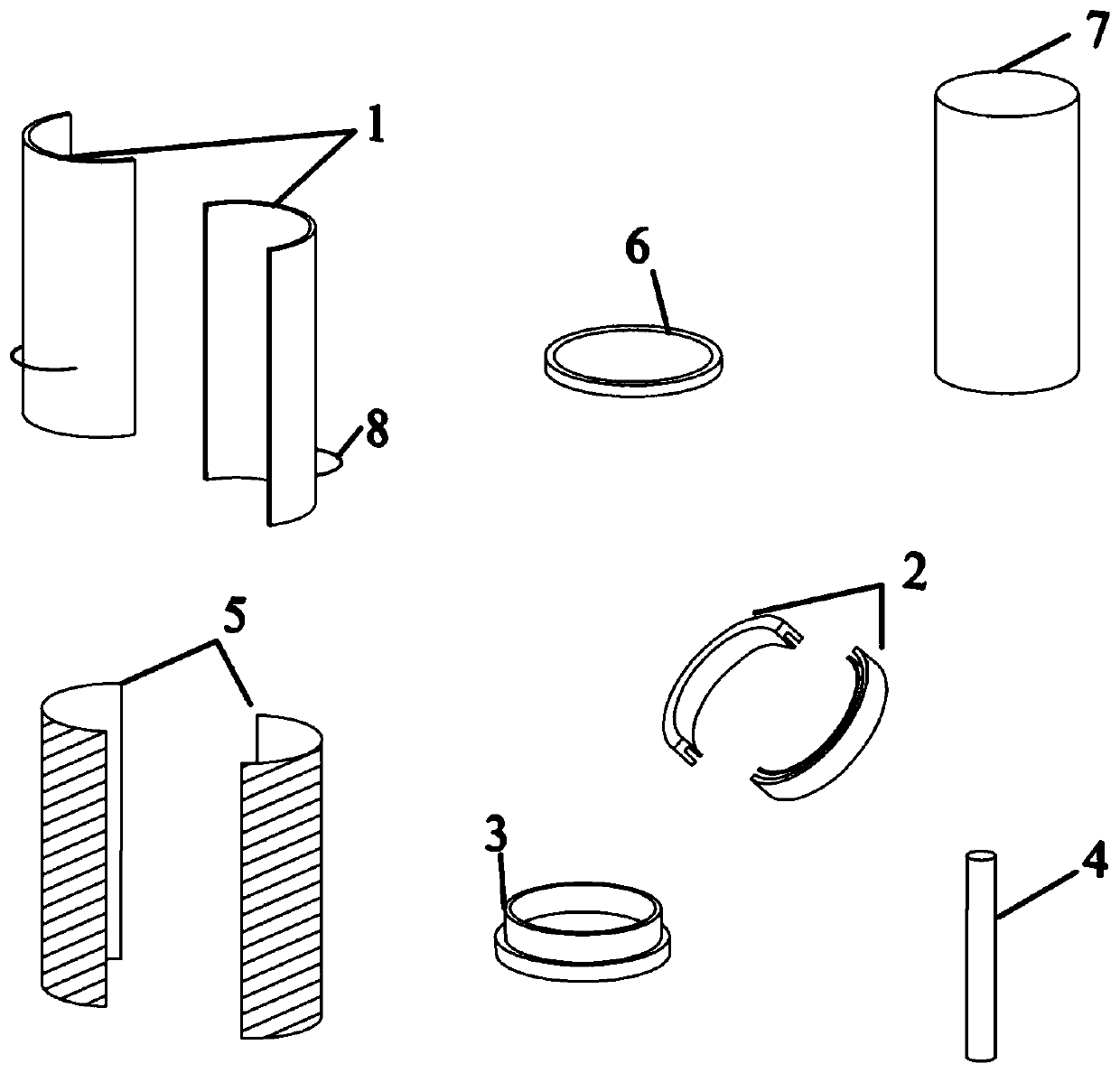

[0018] The invention provides a cohesive soil sample preparation device used for geotechnical tests and a method of use. See Figure 1, figure 1 It is a schematic diagram of the device components of the present invention. Features mainly include mold (1), mold cover (2), base (3), tamping rod (4), plastic wrap (5), clip (6), cohesive soil sample (7), pull ring (8) .

[0019] Further, the completion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com