Microswitch array module

A micro-switch and array technology, applied in the field of micro-switches, can solve the problems of increased manufacturing cost, complex structure, low yield and the like, and achieve the effects of low manufacturing cost, low manufacturing cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

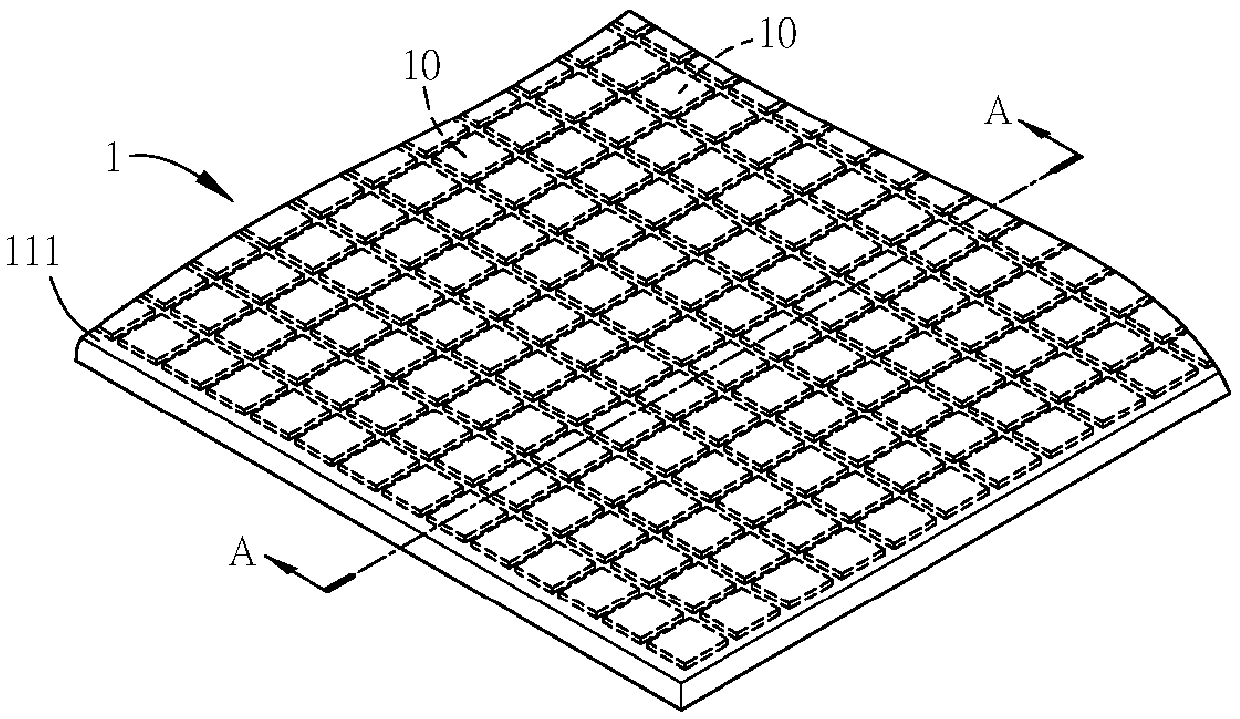

[0023] figure 1 It is a three-dimensional schematic diagram of a micro switch array module according to an embodiment of the present invention. Figure 2A for figure 1 The shown schematic diagram of the structure of the micro switch array module along the A-A section line.

[0024] Such as figure 1 and Figure 2A As shown, the micro switch array module 1 has a plurality of micro switch units 10 arranged in an array. The micro switch unit 10 of this embodiment is configured in a two-dimensional array as an example. Each micro switch unit 10 includes a first transparent substrate 11, a second transparent substrate 13, a transparent conductive layer 12, a first transparent electrode layer 14 and at least one spacer 15.

[0025] The first transparent substrate 11 has a light incident surface 111. The light incident surface 111 of this embodiment is the upper surface of the first transparent substrate 11, and is also the surface of the microswitch array module 1 facing the user, which ...

no. 2 example

[0042] In addition, please refer to Figure 3A and Figure 3B , Which are respectively structural schematic diagrams of a micro switch array module according to another embodiment of the present invention, and Figure 3A The illustrated schematic diagram of the structure of the micro switch electronic writing board composed of the micro switch array module and the cholesterol liquid crystal module.

[0043] The micro switch array module 1 of this embodiment is substantially the same as the micro switch array module described in the previous embodiment. The main difference is that such as Figure 3A As shown, in the micro switch array module 1 of this embodiment, the first transparent electrode layer 14 is disposed on the first surface 131 of the second transparent substrate 13, and extends to the second transparent electrode layer through the first conductive hole 133. On the second surface 132 of the optical substrate 13, corresponding and spaced first transparent electrode laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com