Ceramic heating body for electronic cigarette

A technology for a ceramic heating body and an electronic cigarette, which is applied in the field of electronic cigarettes, can solve the problems of low needle-shaped heating body, lack of temperature in the welding line area, etc., and achieves the effects of reducing power consumption, uniform temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

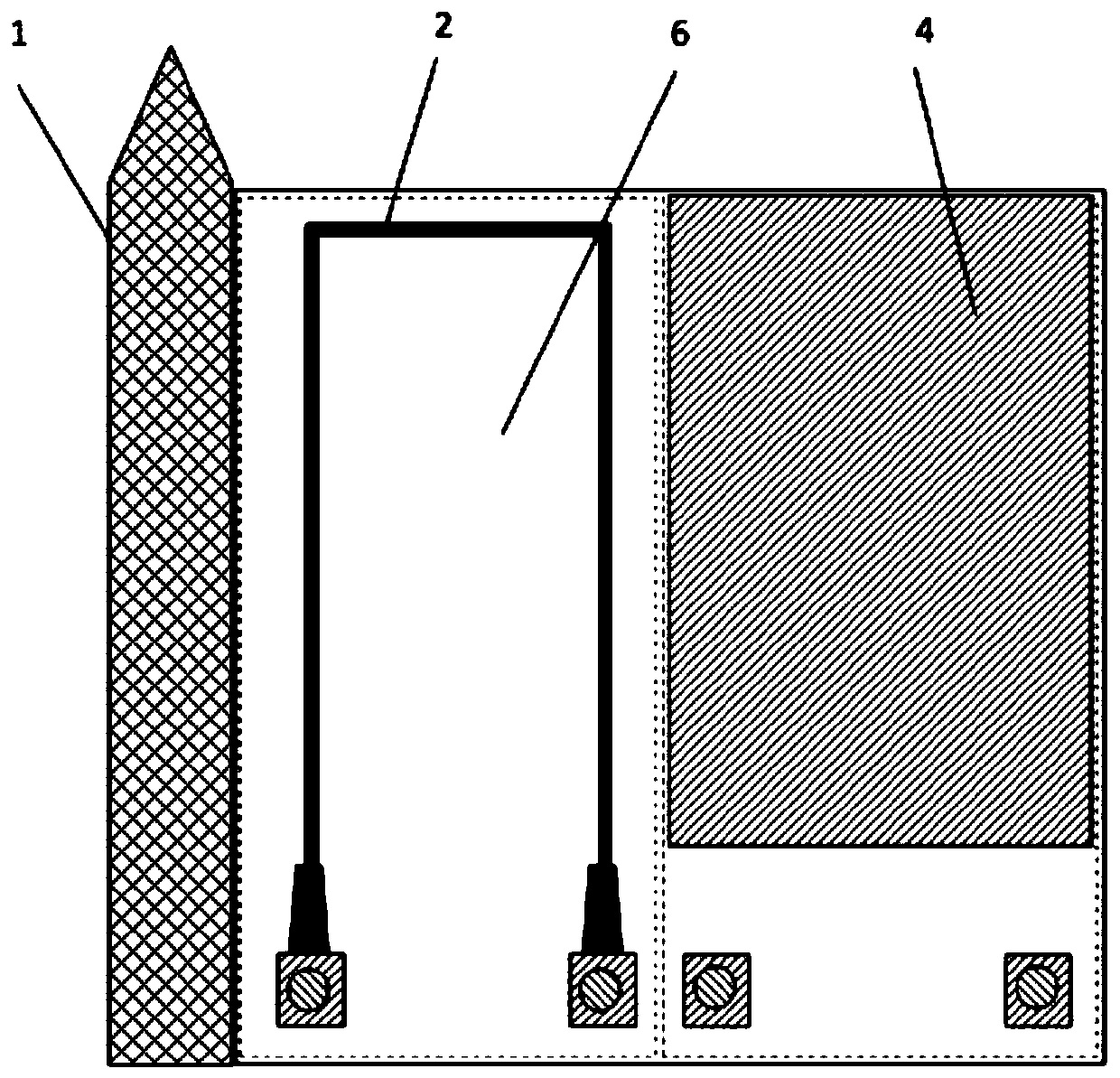

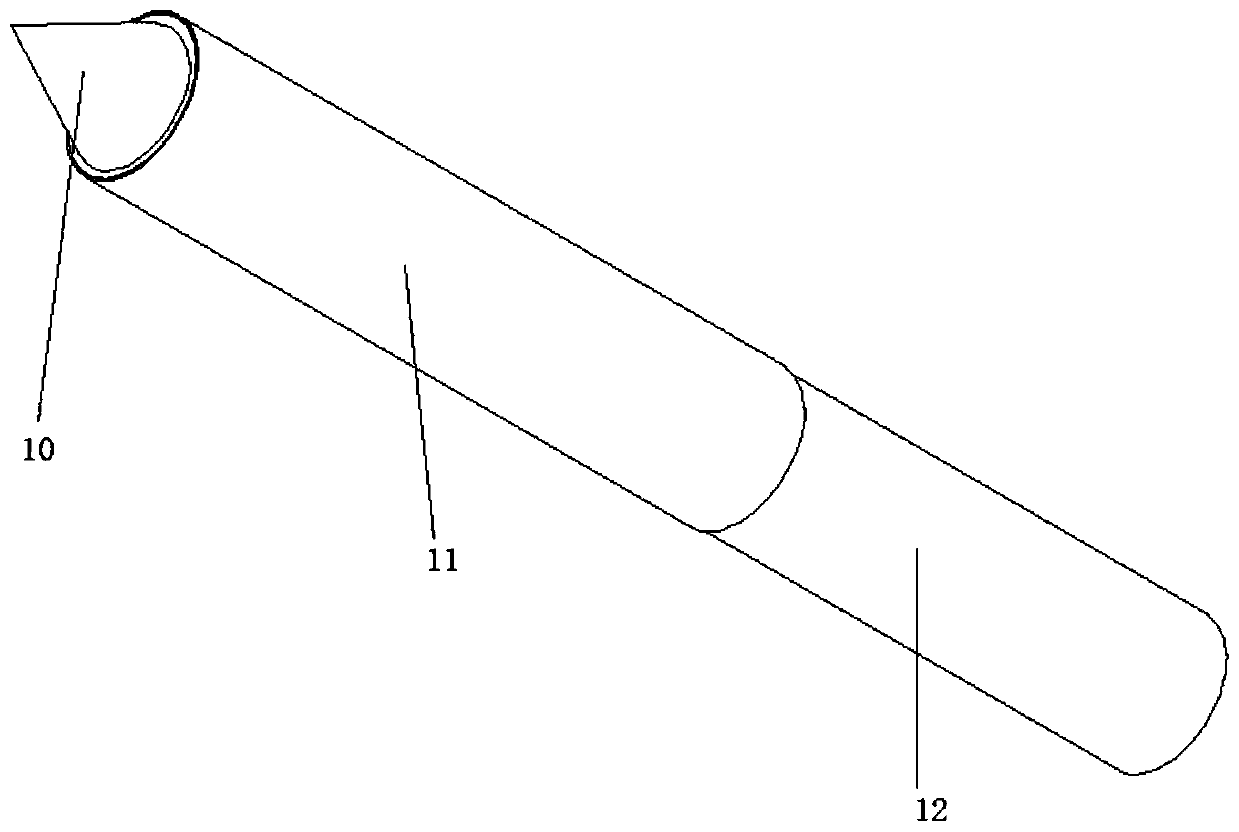

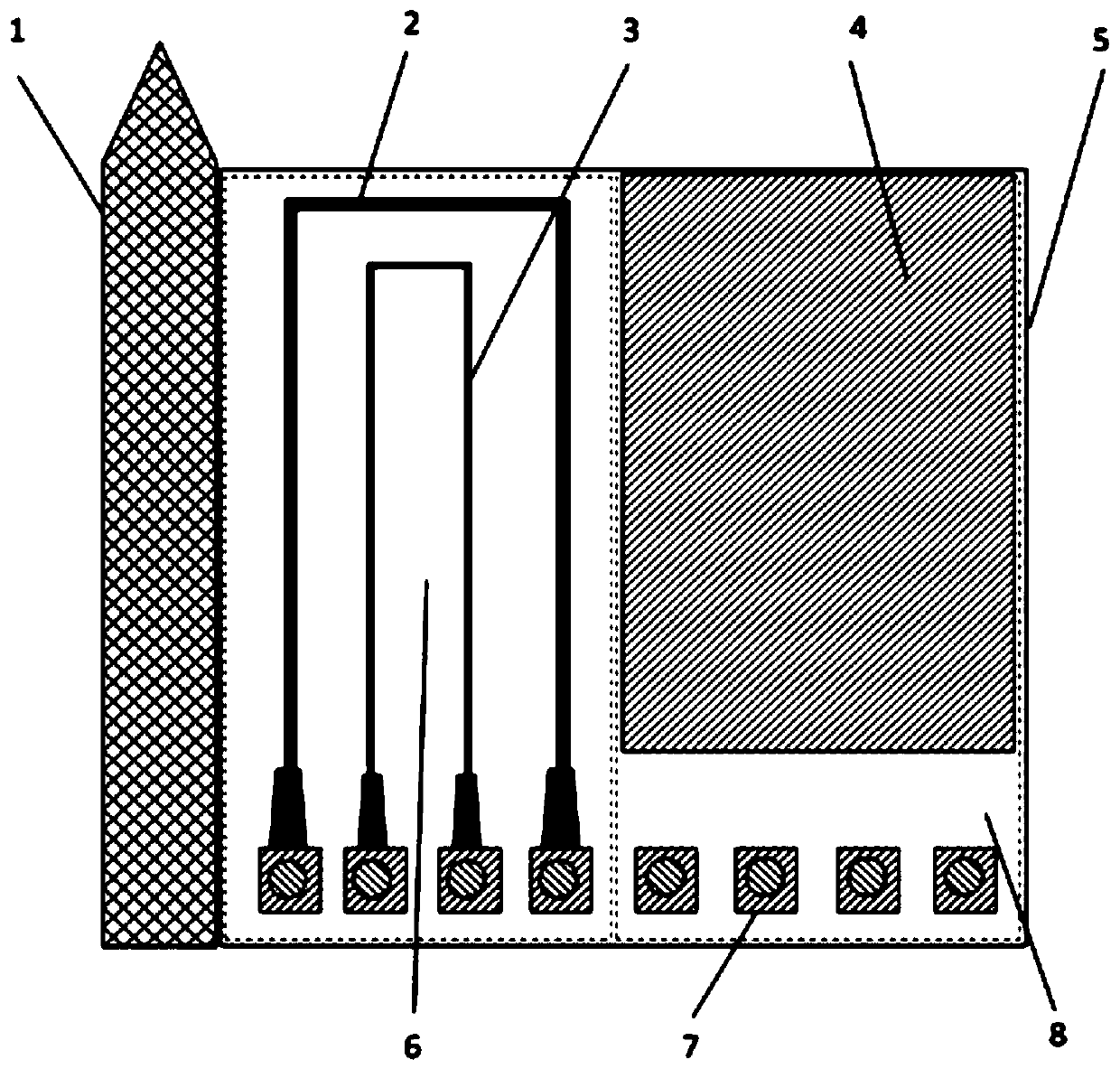

Embodiment 1

[0039] As long as there are three types of e-cigarette ceramic heaters: tubular, sheet, and needle-shaped, they are mainly made of alumina or zirconia ceramics, and high-temperature fired tungsten paste, platinum paste, gold paste, etc. are used as electrode materials, and the cost is relatively high. . Most of them use alumina, and tungsten is used as the electrode material. The main problem is that the thermal conductivity of alumina is high, and the heat diffuses quickly through the ceramic body during heating, which leads to an increase in the temperature of the rear end of the heating body, which not only causes serious heat loss but also causes Other components generate heat, so a flange ring with low thermal conductivity is required to resist heat, and the cost increases. Using zirconia, a low thermal conductivity material, can solve the problems of slow temperature rise, high power consumption, and high back-end temperature of alumina materials, but the matching heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com