High-flux ceramic micro-reactor

A micro-reactor, reactor technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve problems such as limitations, inability to use microreactors, etc. High hardness, reduce research costs, and facilitate heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

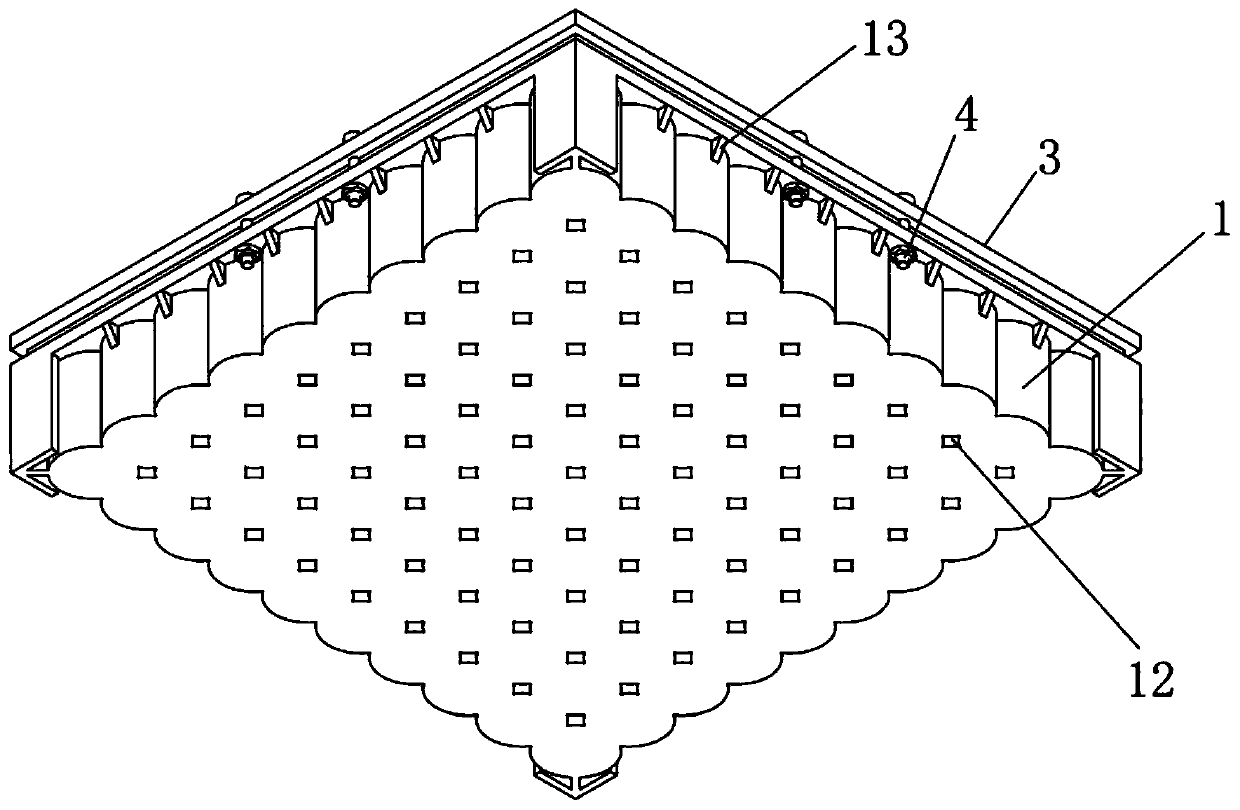

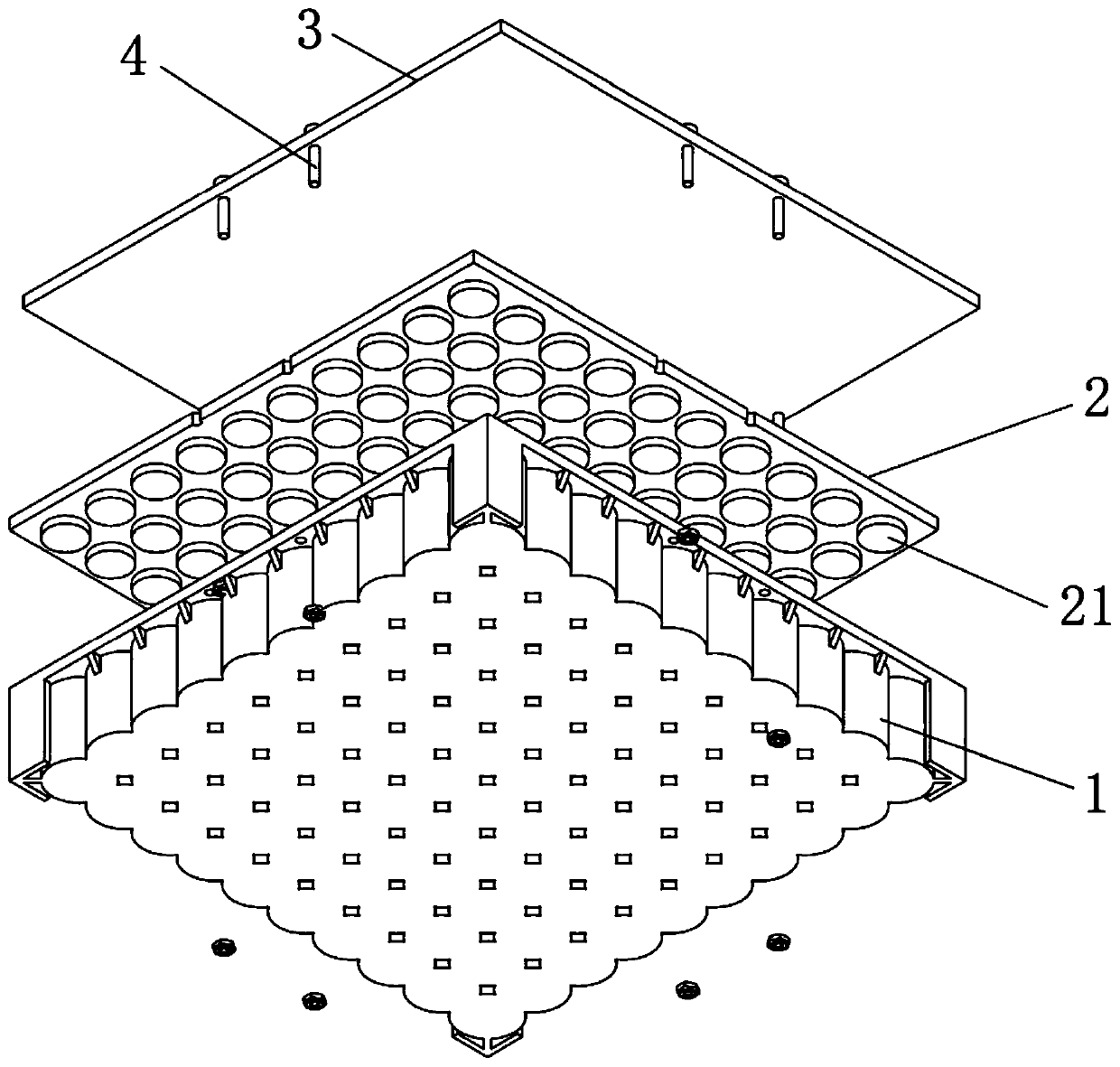

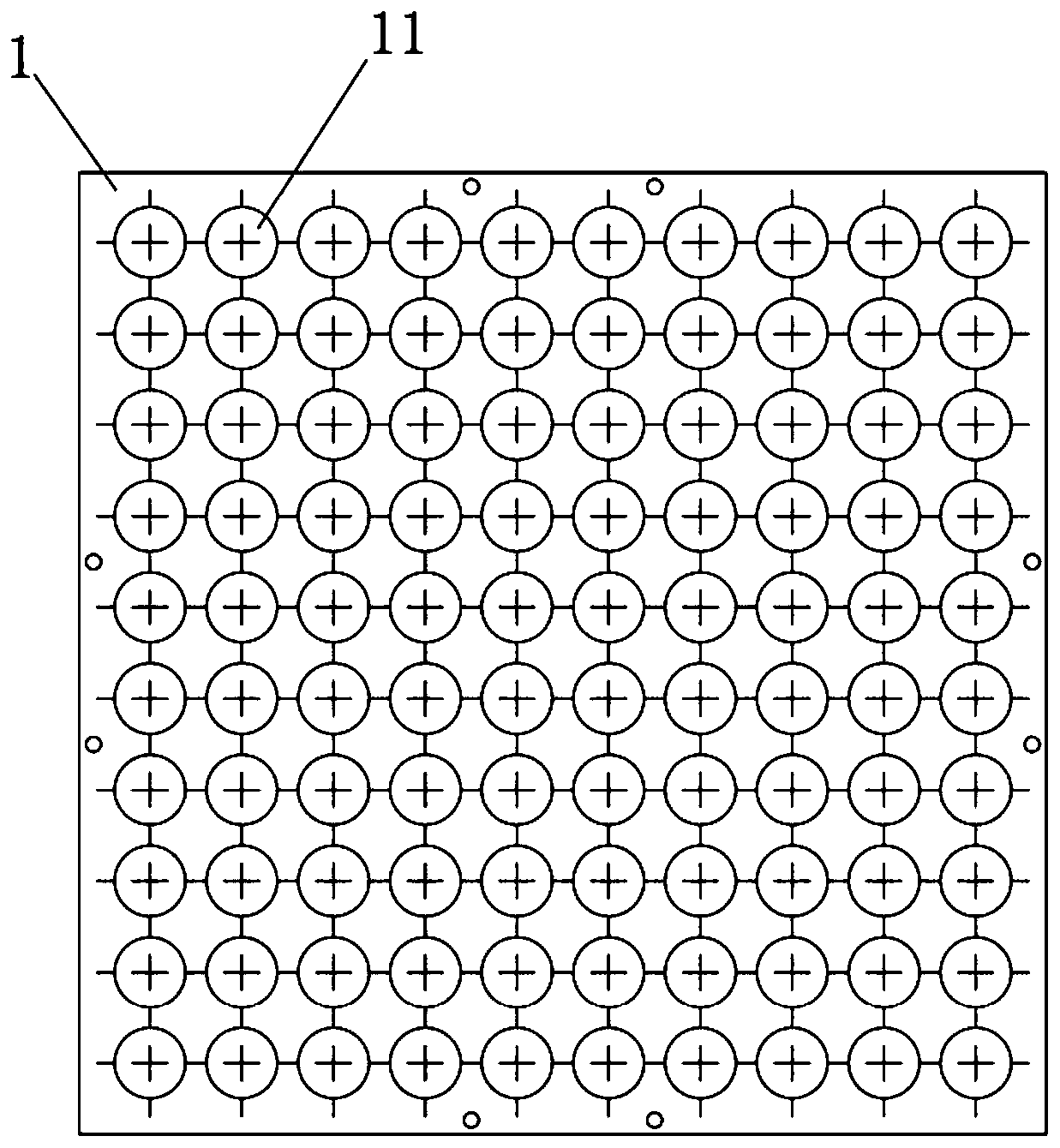

[0026] see Figure 1 to Figure 3 As shown, the high-throughput ceramic microreactor provided by the present invention includes a reactor ceramic main body 1, a rubber gasket 2, and a ceramic cover plate 3. It is solidified, printed and formed, then degreased and sintered, and the sintering temperature is 900°C to 1750°C; the shape and size of the reactor ceramic body 1, rubber gasket 2, and ceramic cover plate 3 match; the reactor ceramic body 1 is There are 4 to 225 reaction microwells 11 distributed in an array, with a spacing of 2 to 5mm, each reaction microwell has a diameter of 5mm to 10mm, and a depth of 10mm to 40mm. Chemical reaction test under corrosive conditions, and different chemical reaction tests can be carried out in different reaction micropores 11; the thickness of the rubber gasket 2 is 1-4mm, laid on the top surface of the reactor ceramic main body 1, and its There are protrusions 21 corresponding to the reaction microholes one by one, and the height of th...

Embodiment 2

[0030] The first step is to use UG software to design a 3*3 9-hole microreactor model. The depth of each hole is 20mm, the hole diameter is 10mm, the hole wall thickness is 2.8mm, and the hole spacing is 3mm. The protrusion diameter of the corresponding rubber gasket is also 10 mm, the protrusion height is 2 mm, and the gasket thickness is 2 mm. The thickness of the ceramic cover plate is 3 mm, and it is fixed with 8 M2 screws, and the screw length is 16 mm. The second step is to export the model to STL format, import the slice into a DLP ceramic light-curing printer to print and shape, and the printing material is zirconia slurry, and the printed green body is as follows: Figure 5 shown. In the third step, put the zirconia microreactor green body in a high-temperature furnace for degreasing and sintering, with a maximum temperature of 1450 degrees, and keep it warm for 2 hours. The fourth step is to prepare 10 mL of Ca(NO3)2·4H2O solution (0.1mol / L), add quantitative (NH4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sintering temperature | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com