Method for improving crystallization compactness of product during casting and pouring of aluminum

A compact and product technology, applied in casting equipment, equipment for feeding molten metal into molds, and manufacturing tools, etc., can solve the problems affecting the density of aluminum parts, the conjunctival film on the surface of molten aluminum, and the elongation, and achieve heat dissipation. Slow, ensure fluidity, prevent the effect of conjunctiva

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

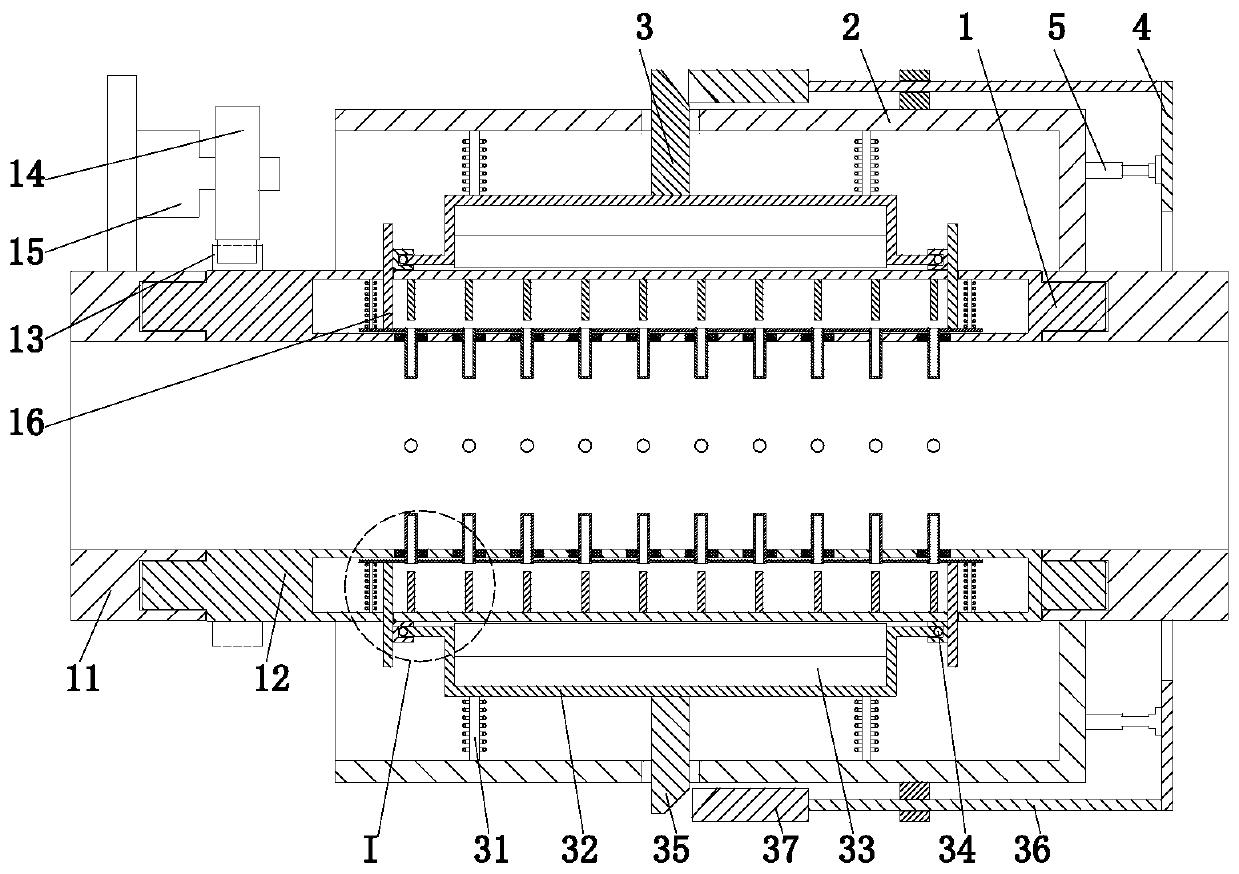

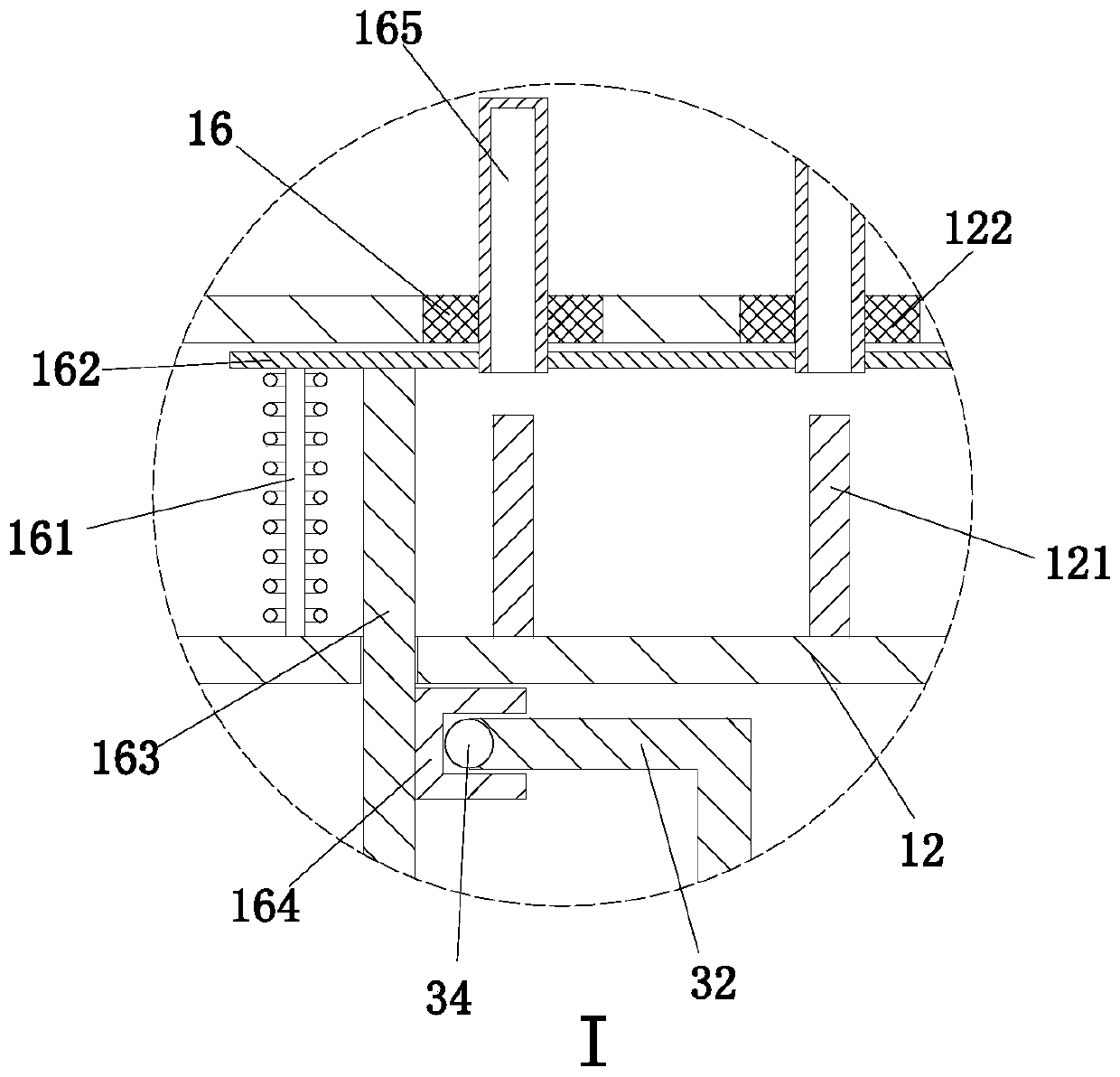

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

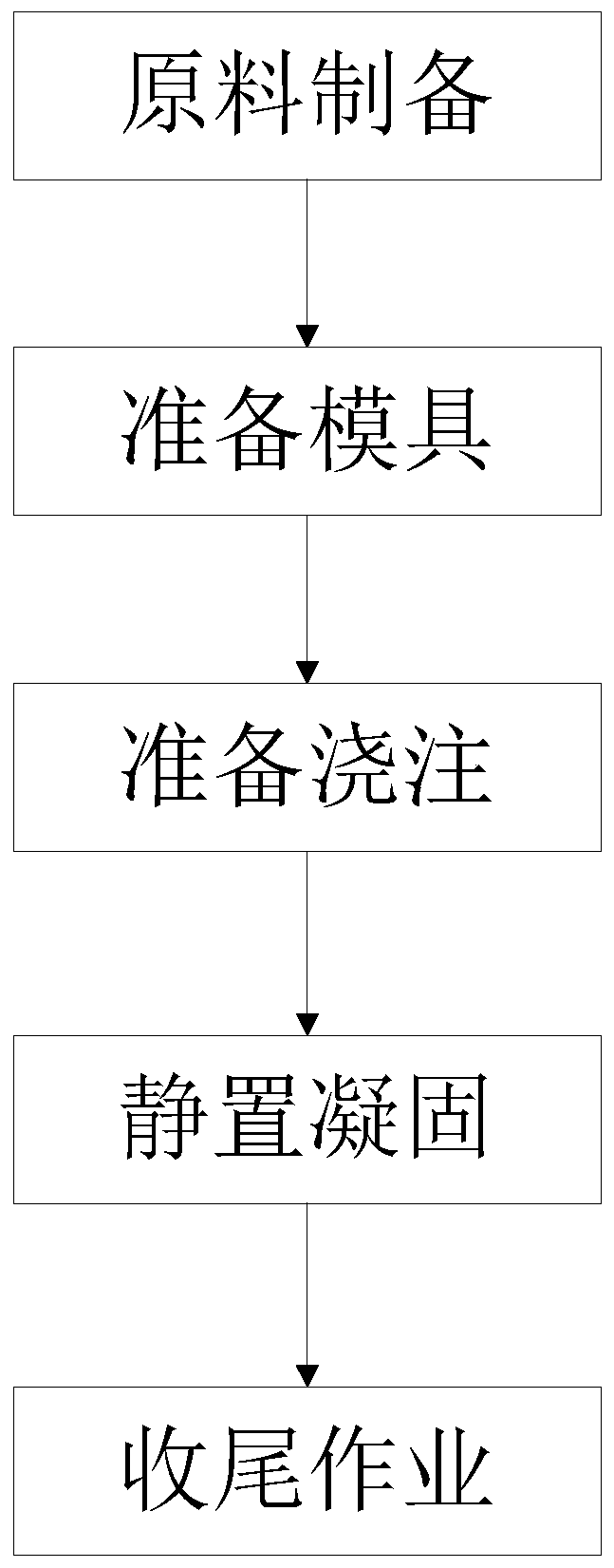

[0028] Such as Figure 1 to Figure 3 As shown, a method for improving the crystallization compactness of the product during casting of aluminum casting mainly includes the following production steps:

[0029] Step 1 Raw material preparation, put the prepared metal aluminum into the heating boiler, heat to 400-450°C at a rate of 20-30°C / h, and then continue to heat at a rate of 50-60°C / h to 600-- At 700°C, the metal aluminum material melts into a liquid state to obtain molten aluminum;

[0030] Step 2 Prepare the mold, combine the pouring mold, and clamp the mold with a clamp;

[0031] Step 3: preparing for pouring, transporting the molten aluminum obtained in step 1 from the heating boiler to the pouring machine, and the pouring machine pours the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com