Method for roughening metal material surface by using laser shock forming technology and application thereof

A technology of laser shock and forming technology, which is applied in the direction of metal processing equipment, laser welding equipment, welding equipment, etc., can solve the problems of difficult local rough surface preparation and service performance degradation, and achieve accurate and controllable surface roughness and preparation range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

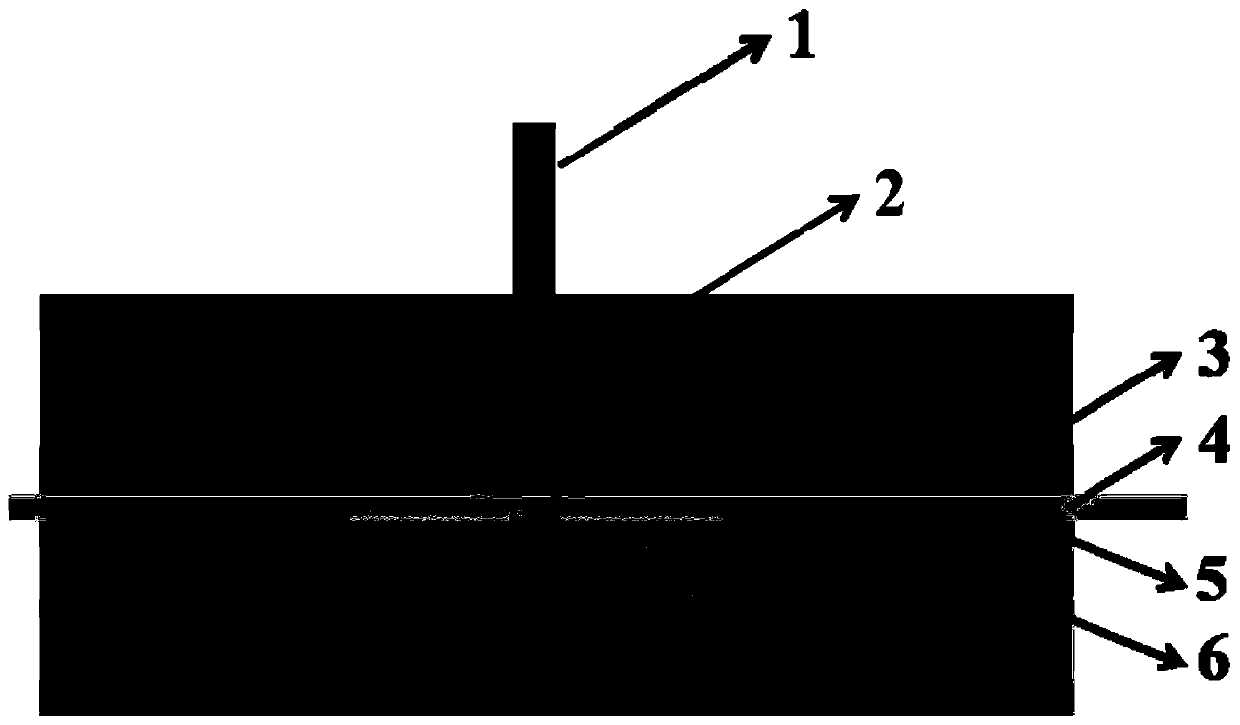

[0046] refer to figure 1 A method for roughening and functionalizing the surface of metal materials by laser shock forming technology, comprising the steps of:

[0047] (1) Preparation of micron imprint mold:

[0048] (1) Select pure aluminum foil as the imprinting mold material, with a thickness of about 0.05 mm; select a pure aluminum plate with a thickness of 2 mm as the surface roughening material, and the surfaces of the pure aluminum foil and the pure aluminum plate have been mechanically polished, and the surface is smooth ;Before laser shock treatment, choose black paint with a thickness of about 0.5mm as the absorbing layer, and choose K9 glass with a thickness of about 3mm as the confinement layer. The parameters of the pulsed laser used are: wavelength 1064nm, energy 1.2J, pulse width A circular beam of 16 ns with a diameter of 2 mm; 200 grit sandpaper was used to prepare the microimprint mold.

[0049] (2) First fix 200-mesh coarse sandpaper 5 on the workbench 6 ...

Embodiment 2

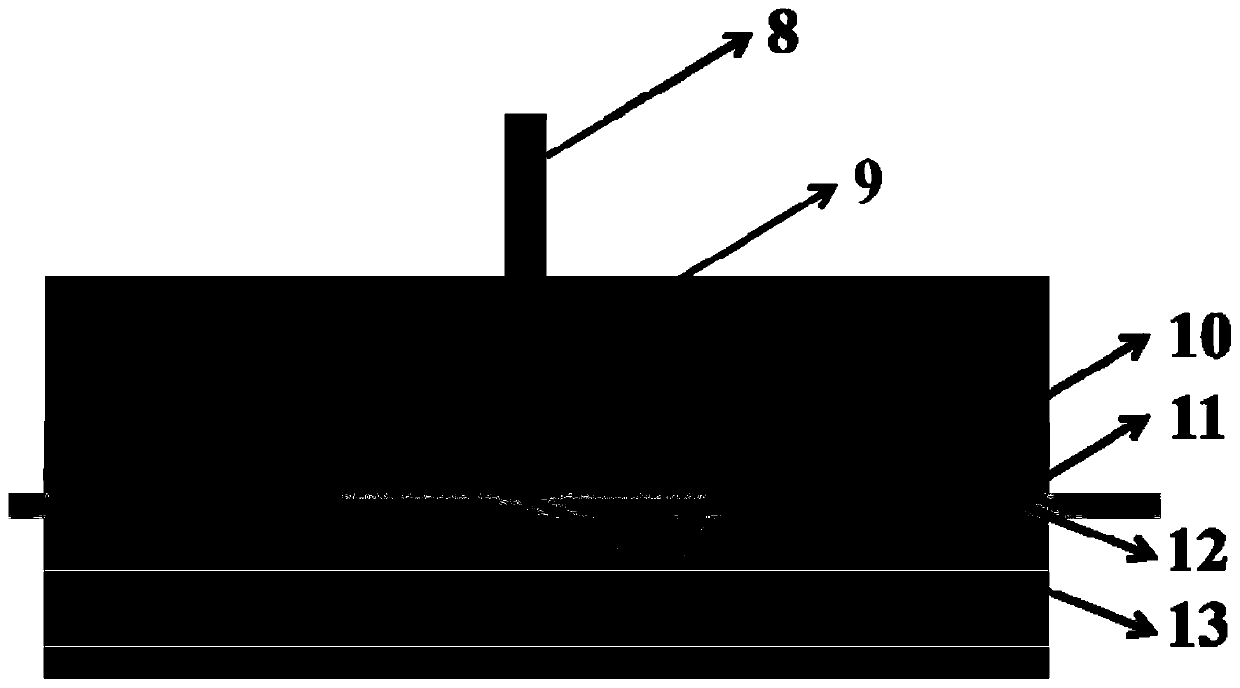

[0067] refer to figure 2 A method for roughening and functionalizing the surface of a metal sheet using laser shock forming technology, comprising the steps of:

[0068] (1) Preparation of micron imprint mold:

[0069] (1) Select pure aluminum foil as the embossing mold material, with a thickness of about 0.05mm; select a pure aluminum sheet with a thickness of 0.45mm as the material to be roughened on the surface, and the surface of the pure aluminum foil and the pure aluminum sheet have been electrochemically Polishing treatment, smooth surface; before laser shock treatment, choose black tape with a thickness of about 0.5mm as the absorbing layer, and choose K9 glass with a thickness of about 3mm as the constraining layer. The parameters of the pulsed laser used are: wavelength 1064nm, energy 3. 2J, a circular beam with a pulse width of 16ns and a diameter of 2mm; 200-mesh coarse sandpaper is used to prepare a micro-imprint mold.

[0070] (2) First fix the pure aluminum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com