Casting deburring device and working method thereof

A technology for deburring and casting, which is used in grinding drive devices, machine tools suitable for grinding workpiece edges, and manufacturing tools, etc., can solve the problems of many burrs, low efficiency, and high price of deburring machines. Easy to operate, improve work efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

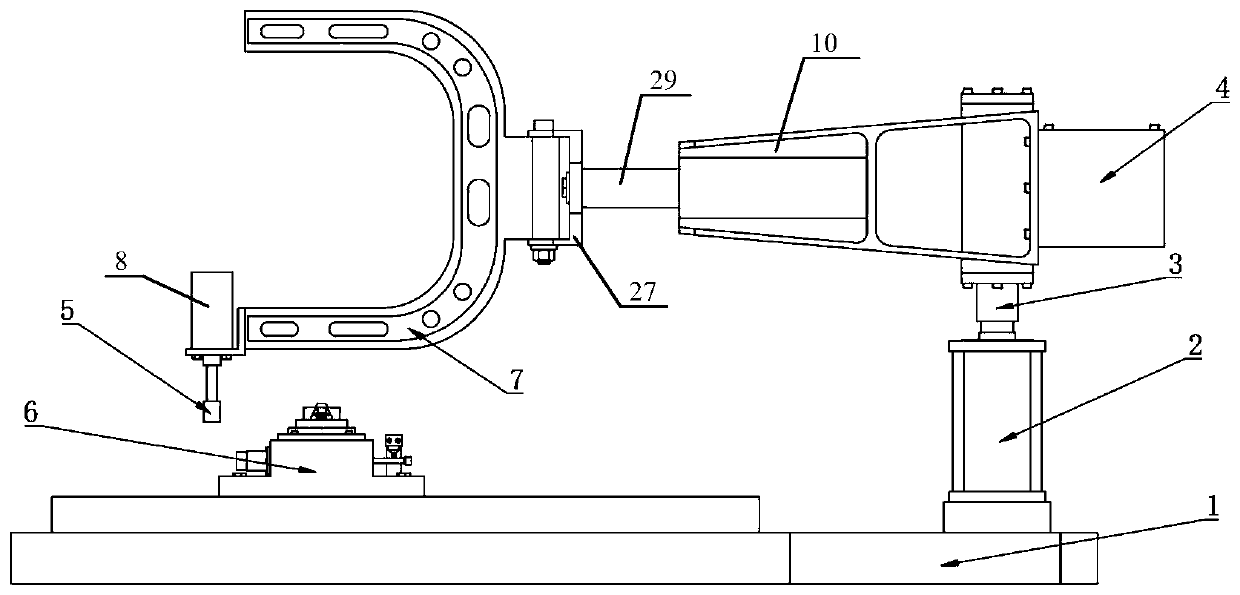

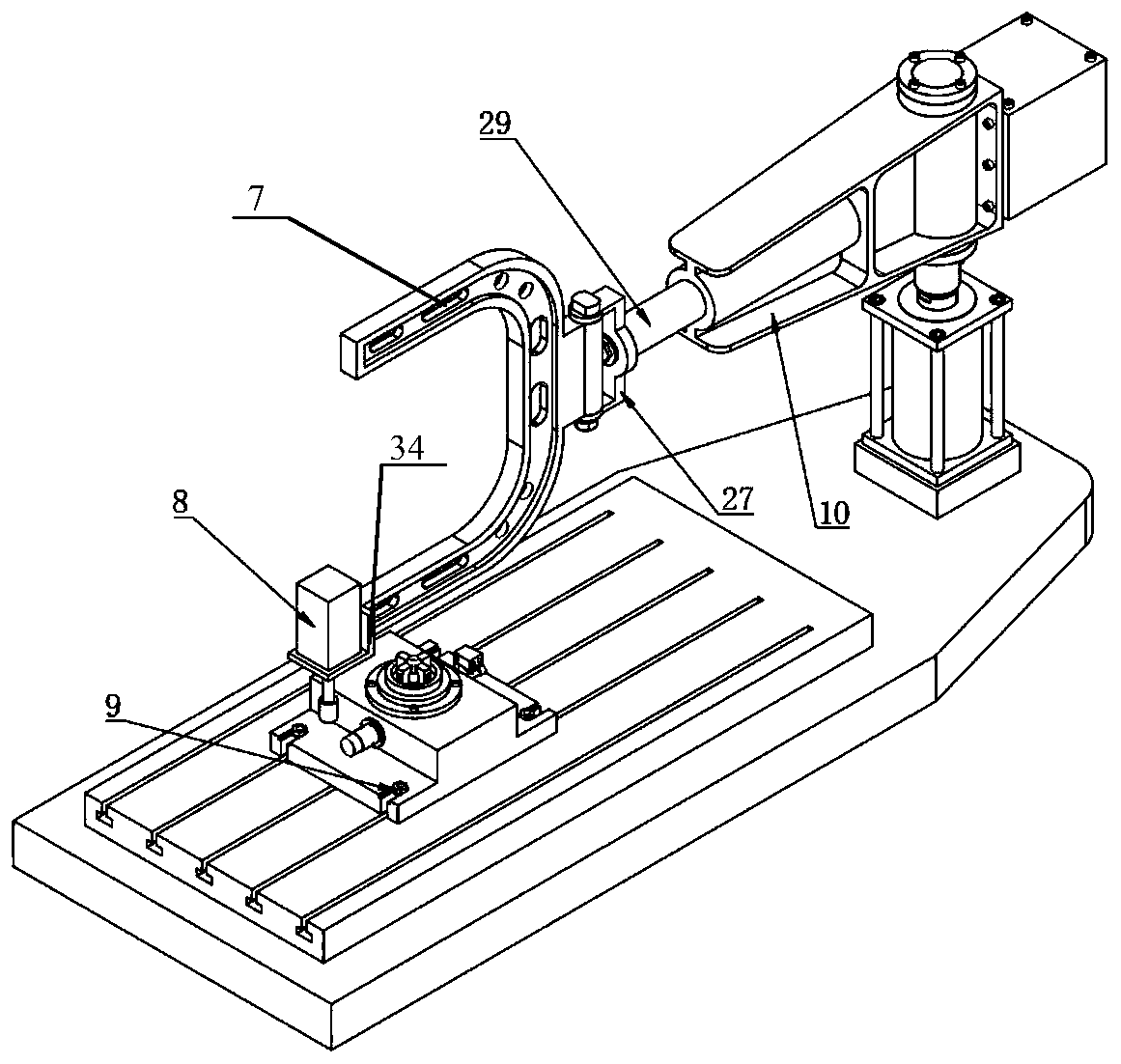

[0043] A casting deburring device, such as Figure 1-7 As shown, it includes a base 1, a clamp body 6 located on one side of the base 1, and a lifting hydraulic cylinder 2 located on the other side of the base 1. The telescopic rod of the lifting hydraulic cylinder 2 is fixedly provided with a main shaft 3, which is rotatably connected to a base Arm 10 and main arm 7, the base arm 10 is fixed on a certain position of the main shaft 3, that is, relatively fixed in the vertical direction, the main arm 7 can move left and right relative to the base arm 10, and can move around the base arm in the horizontal plane 10 free spins;

[0044] The lower end of the main arm 7 is provided with a grinding head 5, the grinding head 5 is driven to rotate by a high-speed motor 8, and the chuck body 6 is used to fix the casting 22 for pre-deburring.

Embodiment 2

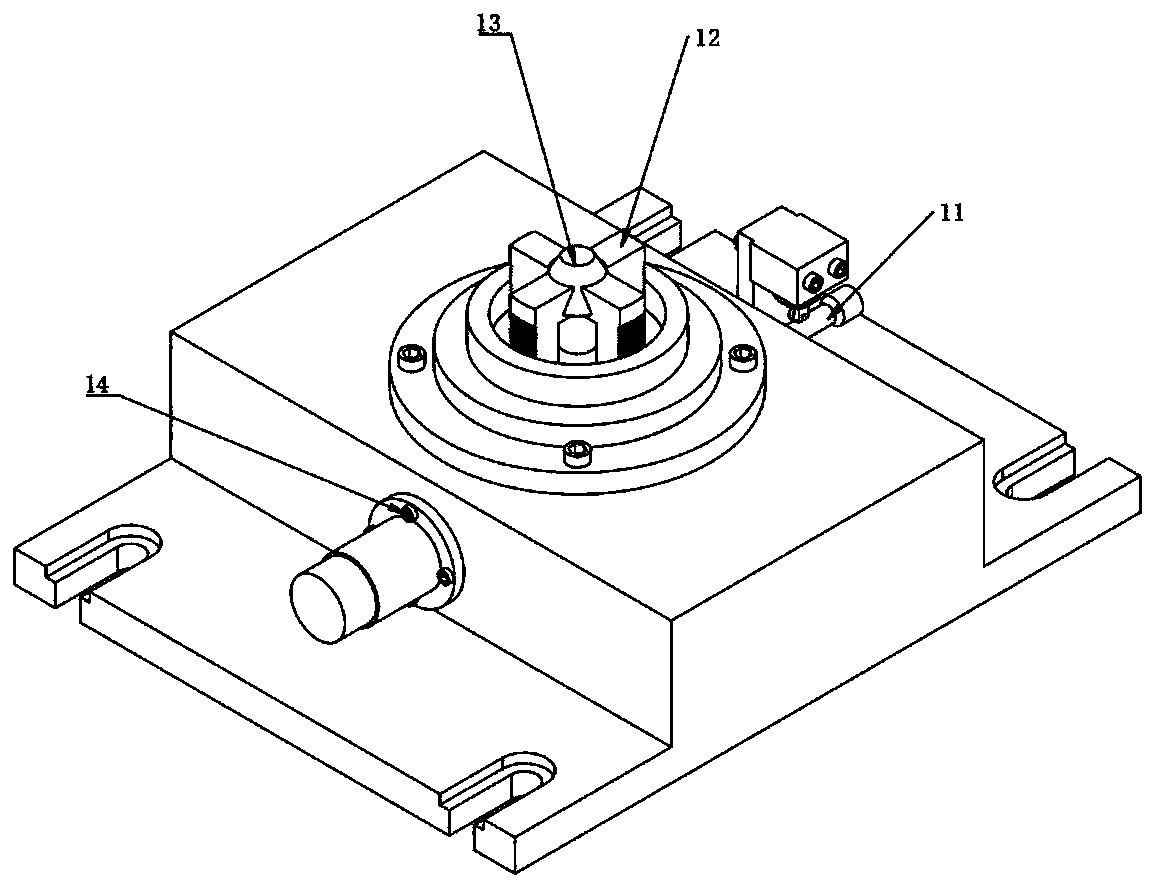

[0046] A casting deburring device, its structure is as shown in embodiment 1, the difference is, as Figure 3-5 As shown, the clamp body 6 includes a clamp body base 15, an end cover 17, an internal expansion body 19 and a traverse hydraulic cylinder 24, the clamp body base 15 and the end cover 17 are fixed on the base 1, and the clamp body base 15 is fixed by the clamp body The bolt 9 is fixed on the base 1, the hydraulic cylinder 24 is fixed on the end cover 17 by the screw 14, the internal expansion body 19 is fixed on the end cover 17, and the telescopic rod of the hydraulic cylinder 24 is connected with a wedge iron push rod 23, The other end of wedge iron push rod 23 is connected with wedge iron 20, and wedge iron 20 is positioned between clamp body base 15 and end cover 17, and end cover 17 is provided with limit hole along the vertical direction, and is provided with push-button hole in limit hole. The rod 21, the bottom of the push rod 21 is in contact with the wedge ir...

Embodiment 3

[0050] A casting deburring device, its structure is as shown in Embodiment 2, the difference is that a free traverse bar 29 is provided between the main arm 7 and the base arm 10, as Figure 6(a) , 6(b) As shown, the base arm 10 is provided with an adjustment passage 28, one end of the free traverse rod 29 is inserted into the adjustment passage 28, and the other end is connected to the main arm 7 through a rotating bracket 27, and the main arm 7 can move laterally relative to the base arm 10 and Rotate in the horizontal plane, the main arm 7 is preferably a U-shaped structure with up and down symmetry, the lower end of the main arm 7 is connected with the grinding head 5, and the upper end can be used for workers to hold and conveniently adjust the position of the grinding head.

[0051] The adjustment channel 28 is non-circular, preferably square, so as to ensure that the free traversing rod can only move left and right, but not rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com