Edge covering device and method applied to glass

A hemming device and hemming technology, applied in the coating and other directions, can solve the problems of long waiting time for demoulding, tearing of the edging material, low efficiency of mold use, etc., and achieve rapid curing and rapid demoulding, high efficiency High and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

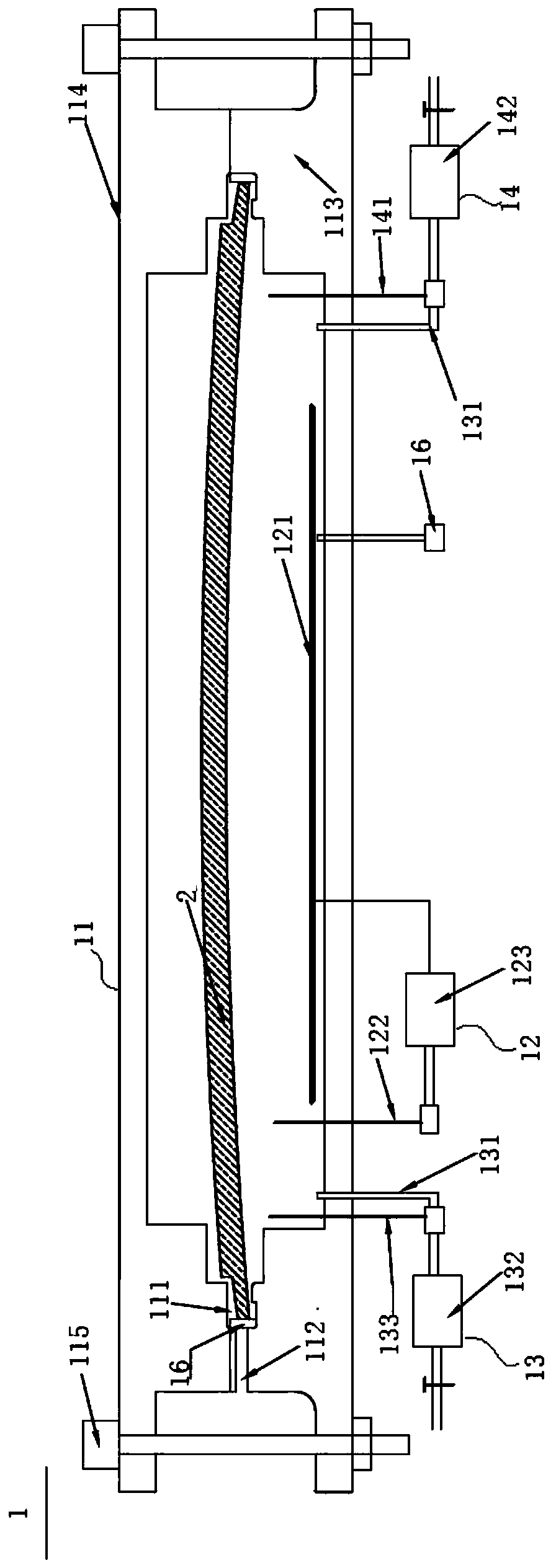

[0047] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic structural view of an edge wrapping device 1 applied to glass according to an embodiment of the present invention. The hemming device 1 applied to glass includes a mold 11, a temperature control system 12, a pressure control system 13 and a displacement control system 14, wherein:

[0048] The mold 11 has a mold cavity 111 and at least one glue injection hole 112 communicating with the mold cavity 111. The mold 11 is used to place the edge wrapping substrate 2. The edge wrapping substrate 2 can be flat laminated glass or curved laminated glass. Glass, but not limited to. And when the edge-wrapping base material 2 is placed in the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com