Electrostatic point printing device based on piezoelectric vibration

A piezoelectric vibration and piezoelectric vibration element technology is applied in the field of piezoelectric vibration-based electrostatic spotting devices, which can solve the problems of limited printing materials, easy whipping, and difficulty in control, and achieve precise control and good application prospects. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

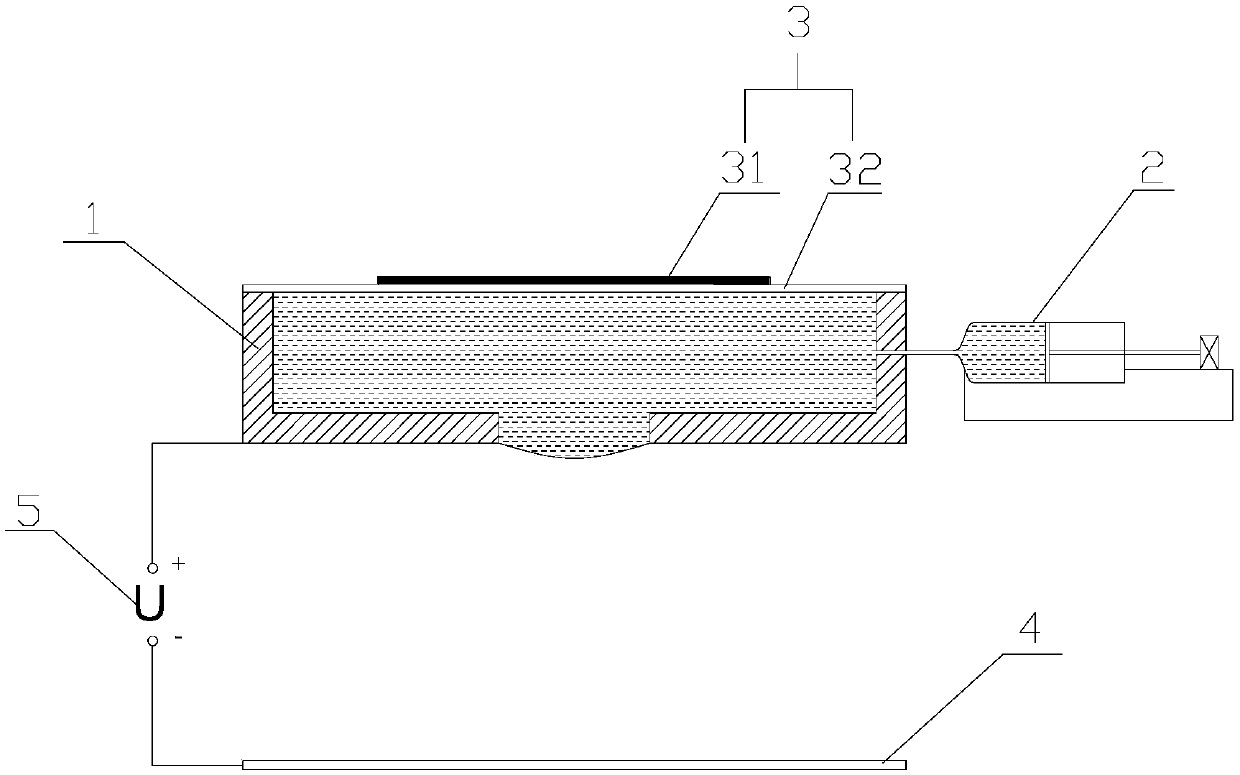

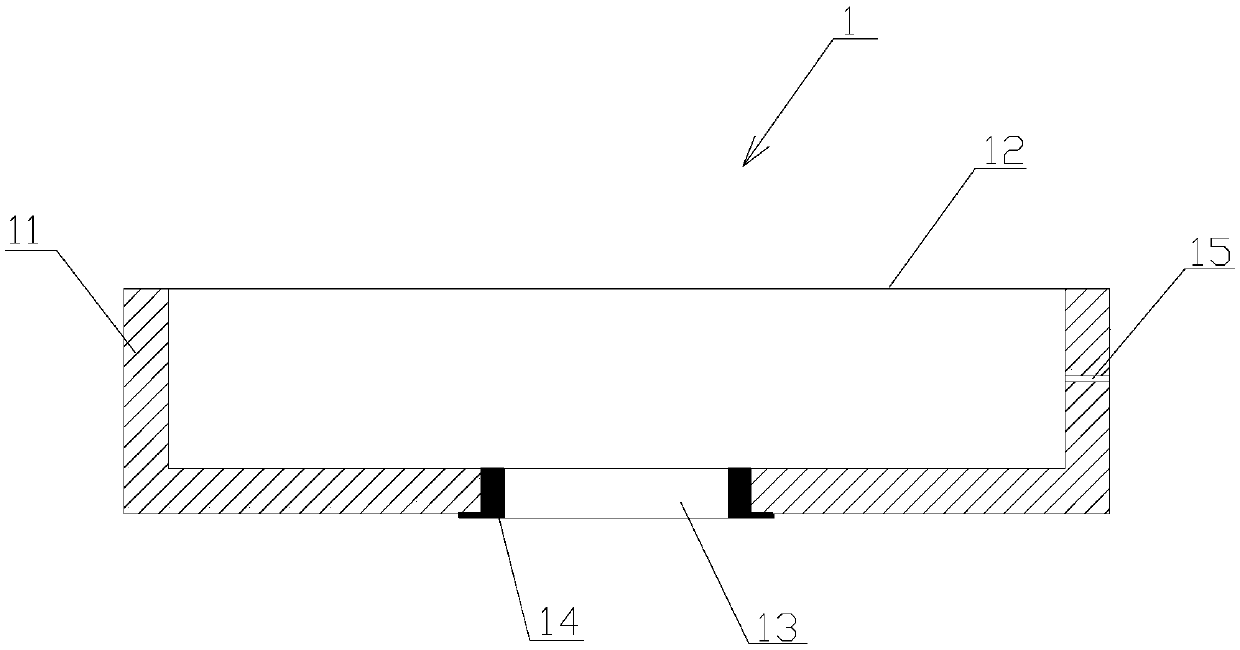

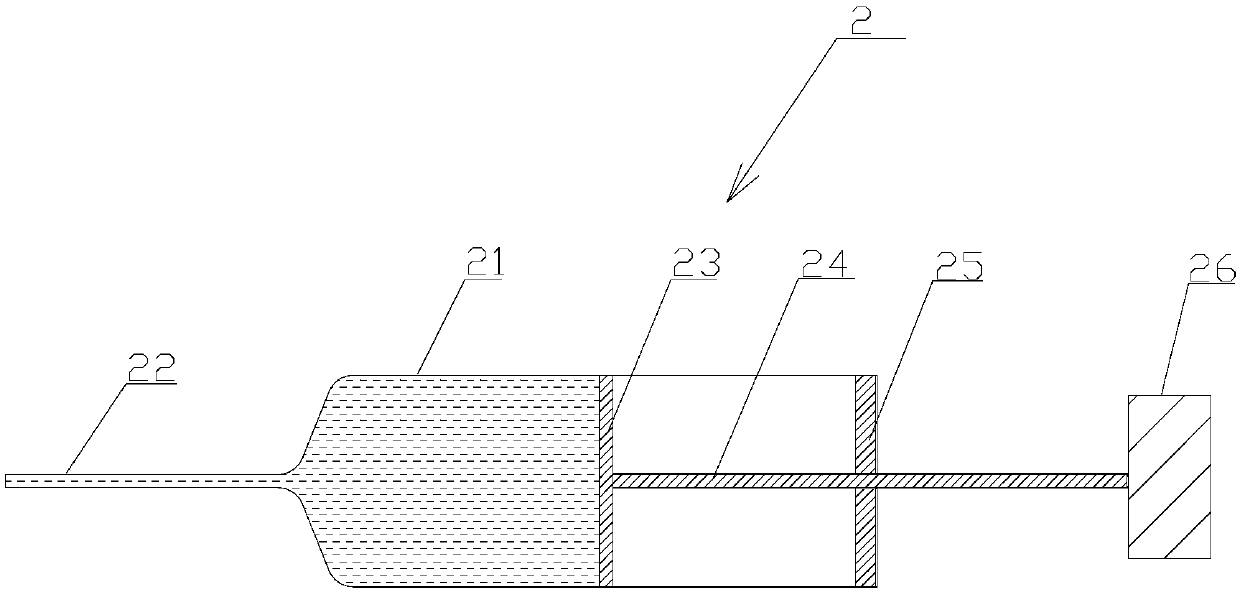

[0030] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-10 As shown, this embodiment provides an electrostatic dotting device based on piezoelectric vibration, including a liquid storage device 1 and a liquid supply device 2, the liquid storage device 1 is used to store the liquid to be dotted, and the liquid storage device 1 includes a storage device 1 and a liquid supply device 2. The liquid housing 11, the liquid storage housing 11 is a hollow cavity structure, the specific shape is not limited, it can be a hollow cylinder, a hollow cuboid, a hollow sphere, etc., the liquid to be dispensed is filled with the liquid storage housing 11, preferably, the liquid storage The material of the casing 11 is insulating material. The liquid storage housing 11 is provided with an opening 12 and a liquid outlet 13 opposite to each other, the opening 12 is provided with a piezoelectric vibrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com