Balloon catheter bonding device

A balloon catheter and bonding device technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of low bonding efficiency, weak bonding, and air bubbles at the bonding point, and achieves simple control, The effect of saving moving time and precisely controlling the length and time of thermal bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

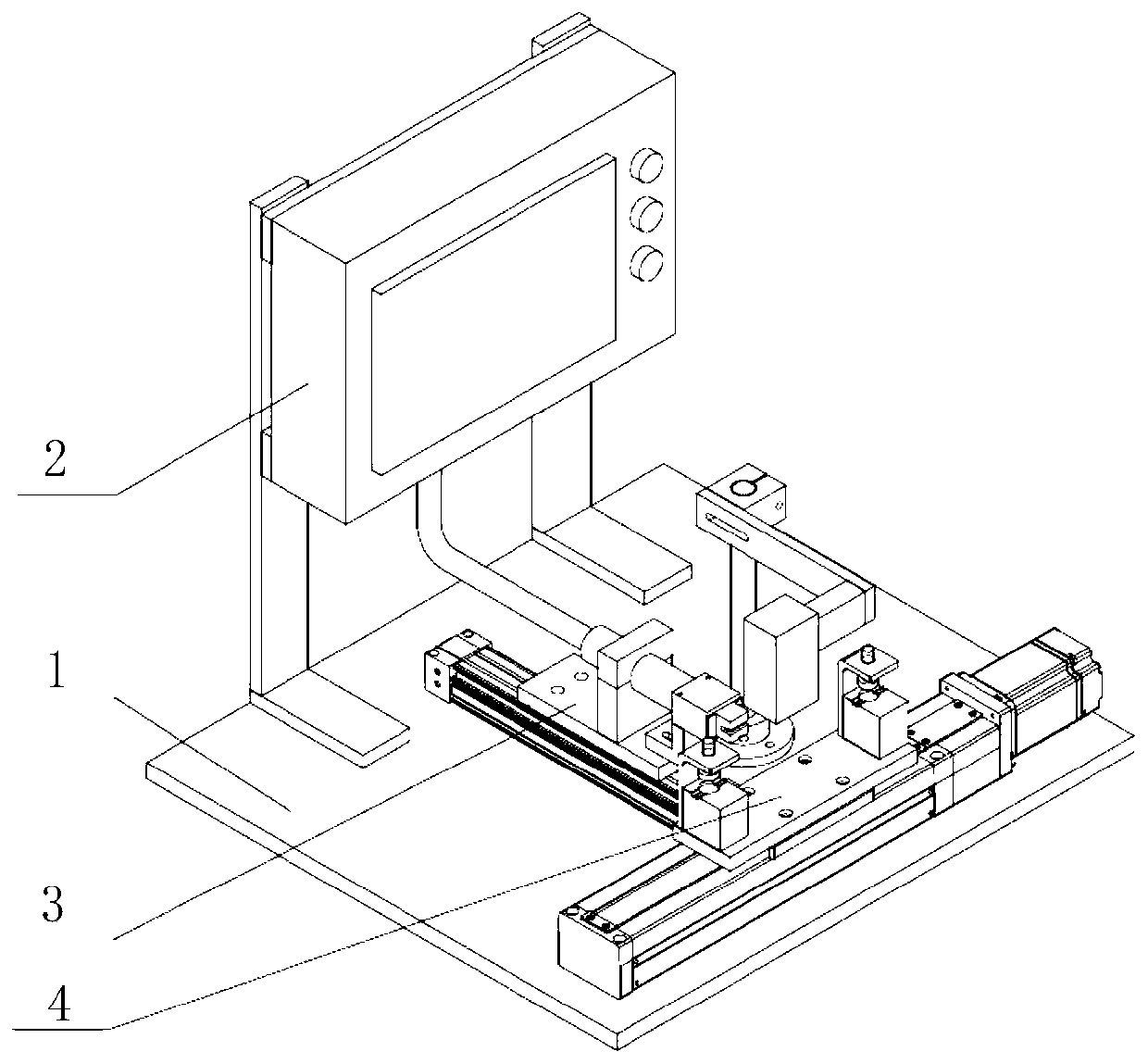

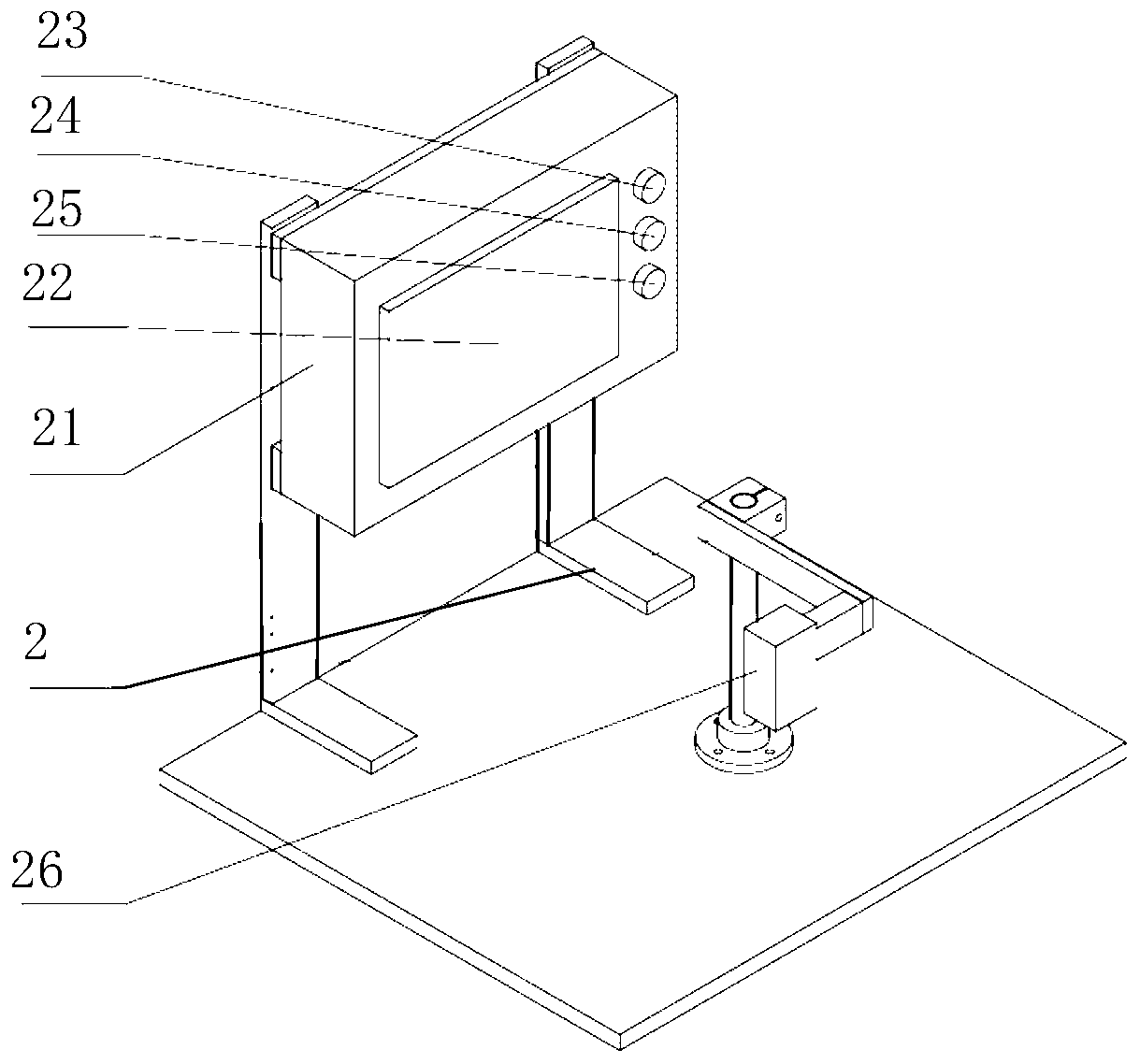

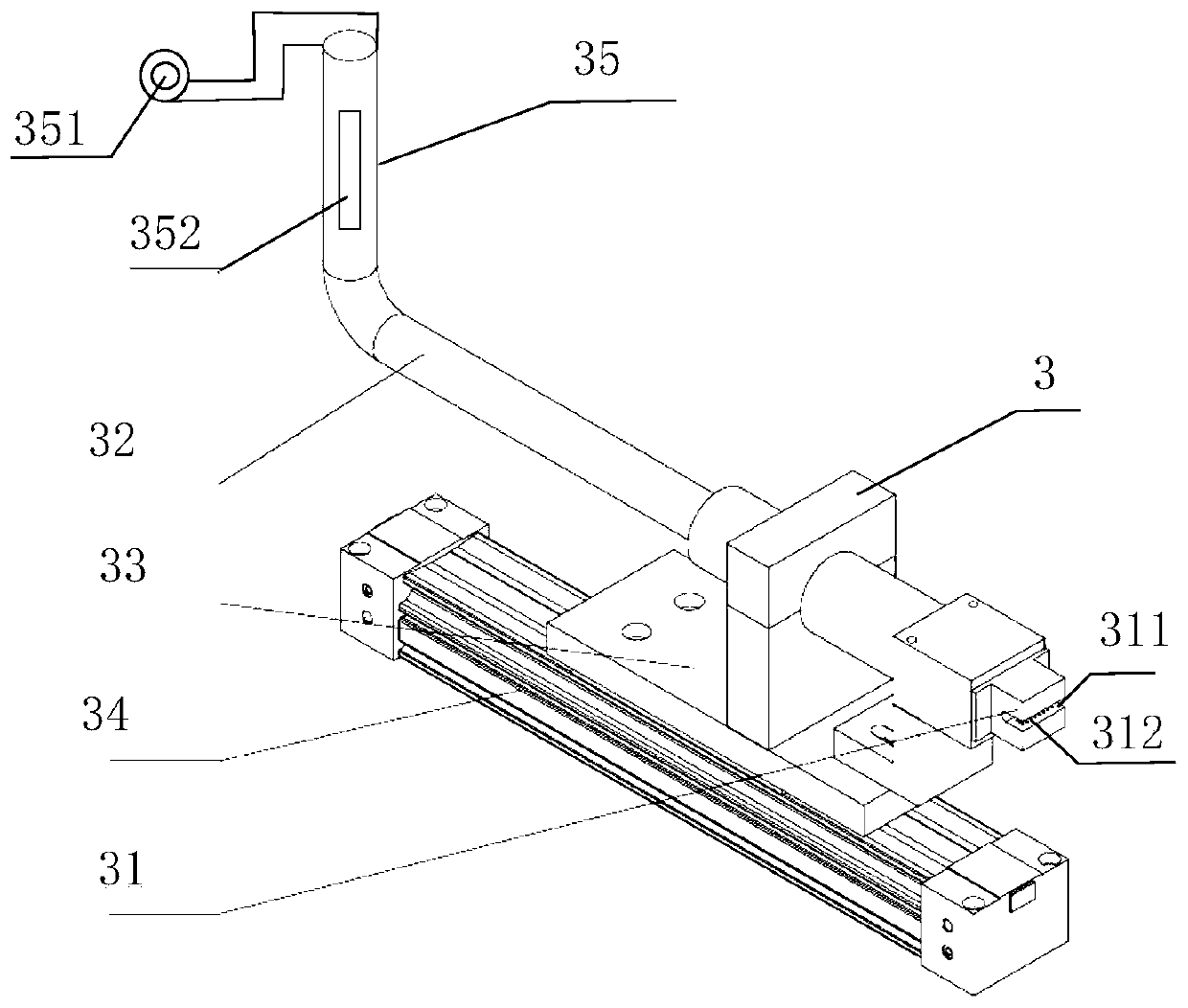

[0029] Such as figure 1 As shown, the present invention is provided with a machine base 1, a control mechanism 2, a hot air bonding mechanism 3, and a balloon catheter fixing mechanism 4, and the control mechanism 2, the hot air bonding mechanism 3 and the balloon catheter fixing mechanism 4 are all arranged on the machine base 1, the machine base 1 is used to support the whole device to ensure the smooth operation of the whole device during use; the balloon catheter fixing mechanism 4 is used to clamp the balloon catheter, and can drive the balloon catheter to move axially along the balloon catheter; The hot air bonding mechanism 3 is used to provide hot air to the balloon catheter, so that each part of the tube assembly of the balloon catheter can be thermally bonded, and can control the air volume and temperature of the hot air flowing out; the hot air bonding mechanism 3 and the balloon catheter fixing mechanism 4 are all connected with control mechanism 2, and control mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com