Three-dimensional hydraulic jacking machine and three-dimensional jacking system

A jacking machine and hydraulic technology, applied in the direction of lifting devices, etc., can solve the problems of limited movement range of hydraulic jacks, inability to be moved by jacking equipment in multiple directions, and inability to adapt, so as to achieve flexible lifting, improve convenience and practicability , Improve the effect of pushing tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

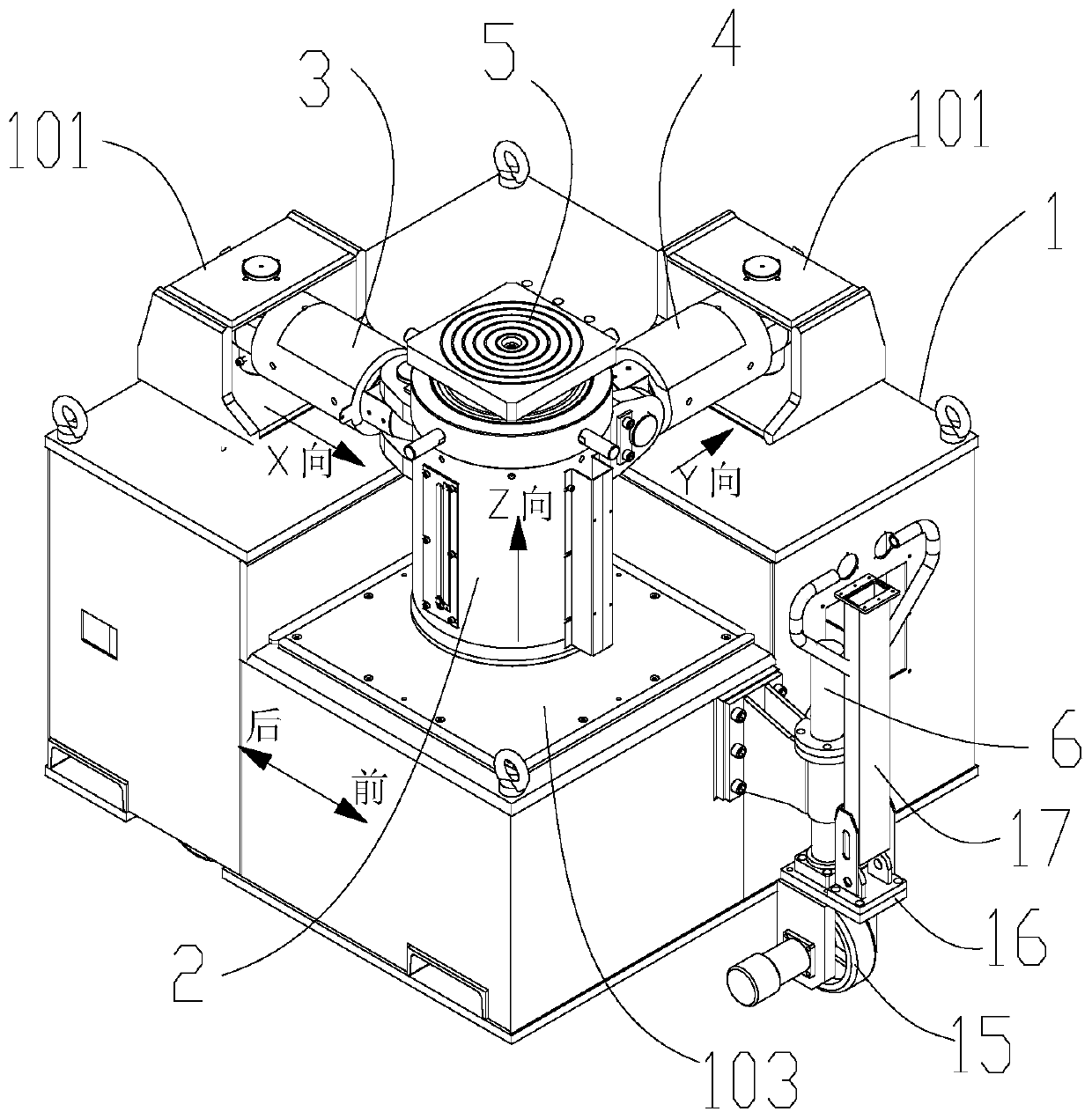

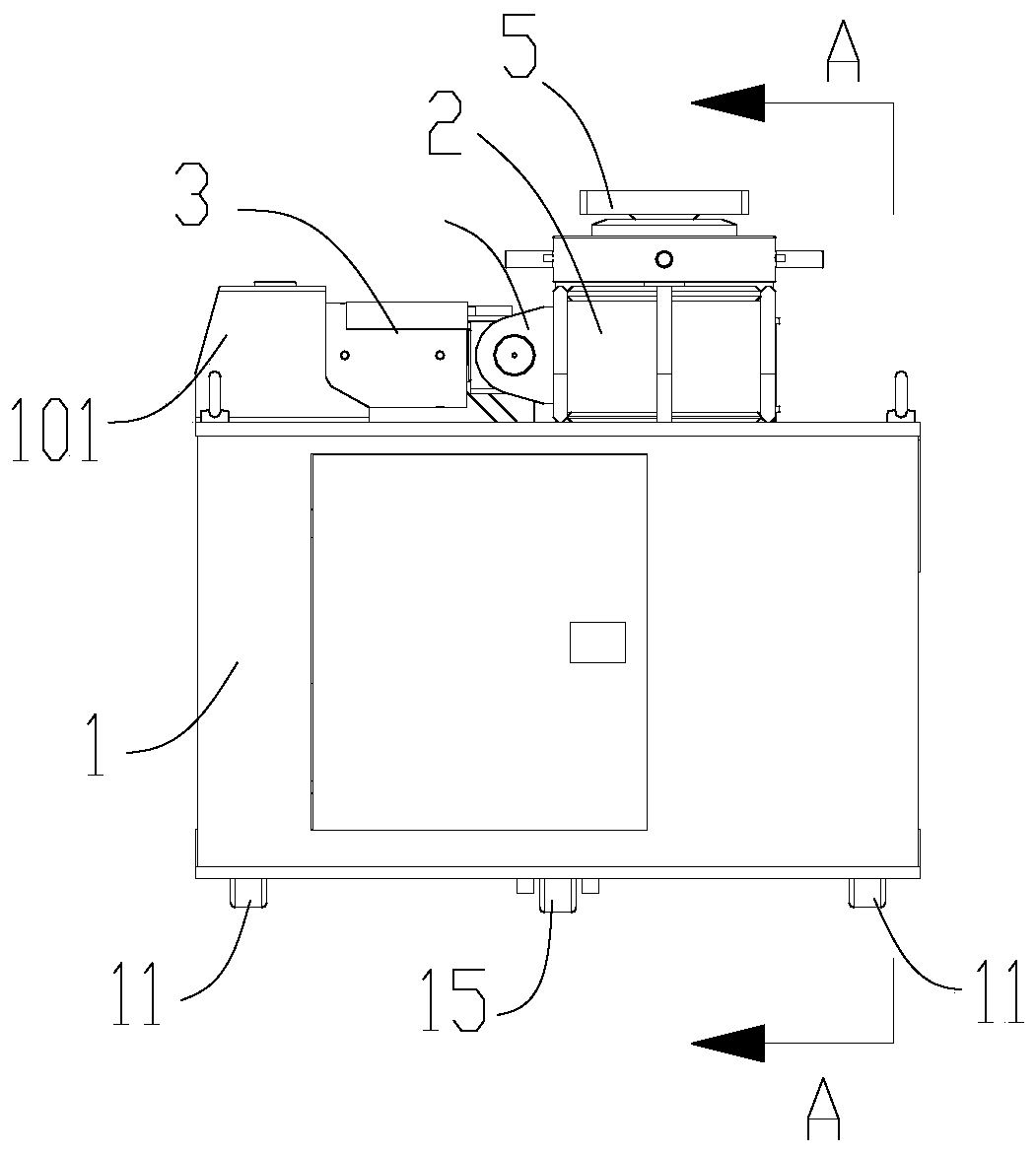

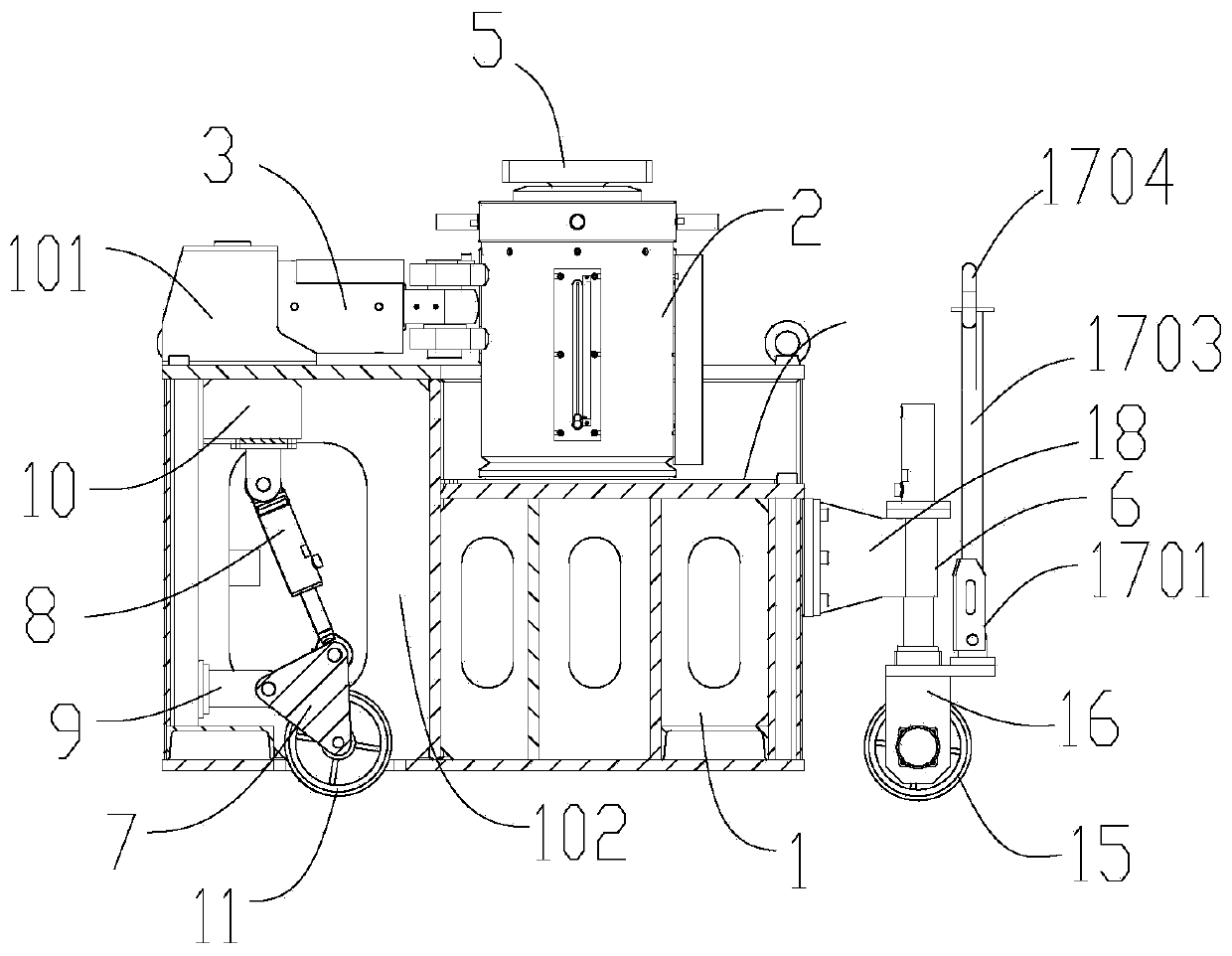

[0052] Example 1, such as Figure 1-Figure 5 As shown, a three-dimensional hydraulic jacking machine includes a vehicle frame 1, a main cylinder 2 located on the top of the vehicle frame 1 and adapted to slide horizontally along the surface of the vehicle frame 1, and a first side located on the circumferential side of the main cylinder 2 To the oil cylinder 3 and the second side oil cylinder 4, and the road wheel assembly suitable for driving the vehicle frame 1 to walk. The vehicle frame 1 has an approximate square structure, and the main oil cylinder 2, the first lateral oil cylinder 3 and the second lateral oil cylinder 4 all adopt high-pressure oil cylinders, and the system pressure is generally 70-80 MPa.

[0053] One end of the first lateral oil cylinder 3 and the second lateral oil cylinder 4 away from the main oil cylinder 2 are both connected to the vehicle frame 1; The oil cylinder 4 expands and contracts along the Y direction. The traveling wheel assembly is used...

Embodiment 2

[0061] Embodiment 2, on the basis of embodiment 1, as Figure 3-Figure 6 As shown, the top of the main oil cylinder 2 is provided with a ball seat assembly 5, and the ball seat assembly 5 includes a ball seat 502, a ball head 501 and a fixed column 503 connecting the ball seat 502 and the ball head 501, the ball seat 502 and the main ball seat 502 One axial end of the oil cylinder 2 is fixed, the other end of the main oil cylinder 2 is placed on the vehicle frame 1, the upper surface of the ball head 501 is in contact with the equipment to be lifted, the contact surface between the ball seat 502 and the ball head 501 is a spherical surface, and the ball head 501 can move relative to the ball seat 502 along the spherical surface, and the fixed column 503 connects the ball head 501 and the ball seat 502 axially, and has a small axial movement space. Any rotational movement. When pushing the hull, the ball head 501 can produce a small angle change, which is beneficial to fit the...

Embodiment 3

[0063] Embodiment 3, a kind of three-dimensional hydraulic jacking machine, such as figure 1 , figure 2 As shown, it includes a vehicle frame 1, a main oil cylinder 2 located on the top of the vehicle frame 1 and adapted to slide horizontally along the surface of the vehicle frame 1, a first lateral oil cylinder 3 and a second lateral oil cylinder located on the peripheral side of the main oil cylinder 2 Oil cylinder 4, and the walking wheel assembly suitable for driving vehicle frame 1 to walk. The vehicle frame 1 has an approximate square structure, and the main oil cylinder 2, the first lateral oil cylinder 3 and the second lateral oil cylinder 4 all adopt high-pressure oil cylinders, and the system pressure is generally 70-80 MPa.

[0064] One end of the first lateral oil cylinder 3 and the second lateral oil cylinder 4 away from the main oil cylinder 2 are both connected to the vehicle frame 1; The oil cylinder 4 expands and contracts along the Y direction.

[0065] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com