Supercritical foaming nucleating agent and preparation method thereof

A foaming nucleating agent and supercritical technology, applied in the field of foam plastics, can solve the problems of no new nucleating agent, poor versatility of related nucleating agents, single nucleating agent variety, etc., to achieve stable quality and prevent size Stability issues, improved reinforcement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

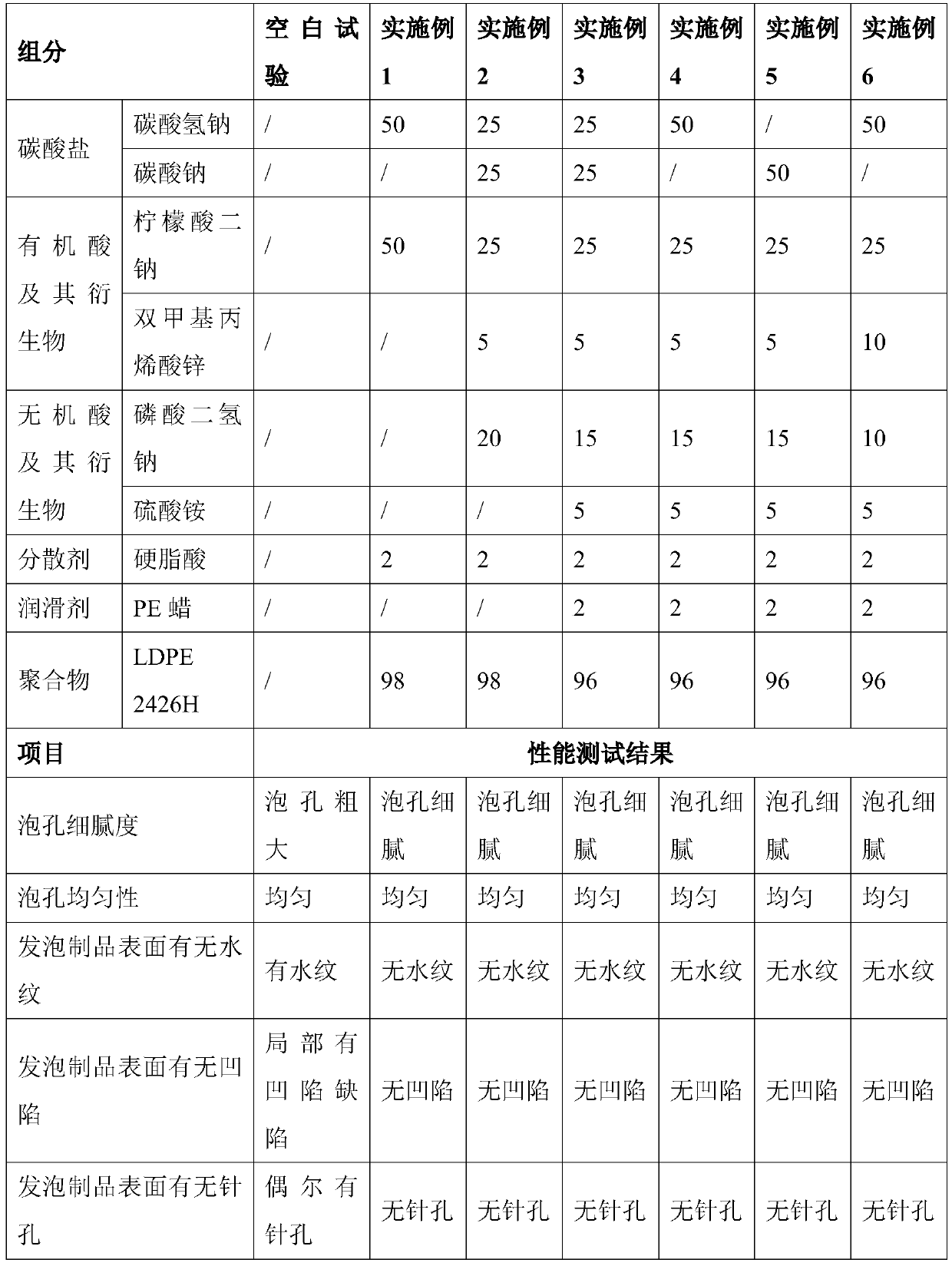

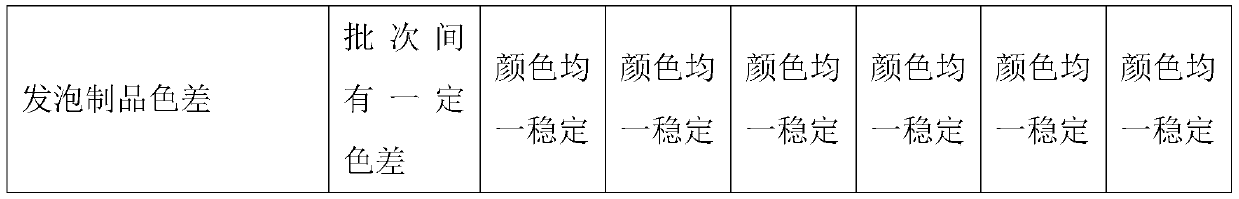

[0041] A kind of supercritical foaming nucleating agent, its formula is shown in Table 1.

[0042] The supercritical foaming nucleating agent is prepared by the following method: the organic acid and its derivatives, the inorganic acid and its derivatives and the carbonate in the raw material are ground into a median particle size of 1-20 microns by jet milling Then add polymer and lubricant to pre-disperse the material in the state of ultrafine powder, and get granular supercritical foaming nucleating agent through banburying and granulation.

[0043] Table 1 (unit: kg)

[0044]

[0045]

[0046] The granular supercritical foaming nucleating agent obtained in each of the above examples is used to produce polypropylene foamed products, and the operation steps of polypropylene supercritical extrusion foaming are as follows:

[0047](1) Set the process conditions of the extruder as follows: Zone 1 170-175°C, Zone 2 180-185°C, Zone 3 190-198°C, Zone 4 198-210°C, die head t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com