Temperature-sensitive plugging colloid for oil and gas fields, preparation method and use method thereof

A technology for leaking colloids and oil and gas fields, applied in chemical instruments and methods, and drilling compositions, etc., can solve problems such as uncontrollable crosslinking time and gel strength, mixed formation fluids, complex construction technology, etc., and achieve good theory The effects of research and practical value, slow particle thickening and stickiness, and simple slurry mixing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0025] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention if ther...

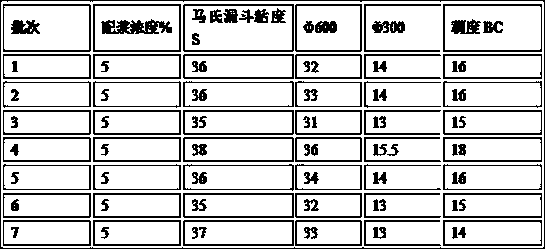

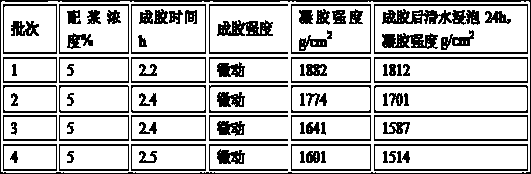

Embodiment 1

[0028] The invention discloses a temperature-sensitive plugging colloid for oil and gas fields. The plugging colloid is composed of modified polyacrylamide, a trivalent cross-linking agent, a water-soluble slow-release agent and a water phase, wherein the parts by weight of each component are : 55~75 parts of modified polyacrylamide, 10~25 parts of trivalent crosslinking agent, 5~20 parts of water-soluble slow-release agent, 45~65 parts of water phase.

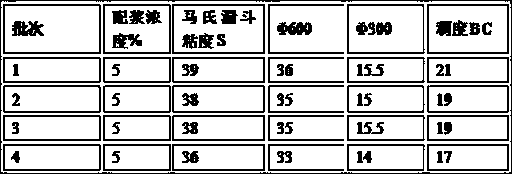

Embodiment 2

[0030] The invention discloses a temperature-sensitive plugging colloid for oil and gas fields. The plugging colloid is composed of modified polyacrylamide, a trivalent cross-linking agent, a water-soluble slow-release agent and a water phase, wherein the parts by weight of each component are : 55~75 parts of modified polyacrylamide, 10~25 parts of trivalent crosslinking agent, 5~20 parts of water-soluble slow-release agent, 45~65 parts of water phase.

[0031] Preferably, the parts by weight of each component are: 60-70 parts of modified polyacrylamide, 13-20 parts of trivalent crosslinking agent, 9-15 parts of water-soluble slow-release agent, and 50-60 parts of water phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com