Manual three-way tolerance adjuster and application and installation method thereof

A regulator and tolerance technology, applied in the field of manual three-way tolerance regulator, can solve the problems of narrow structure, difficult assembly, complex door structure, etc., and meet the requirements of high structure and material strength, low production input cost and high vibration environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

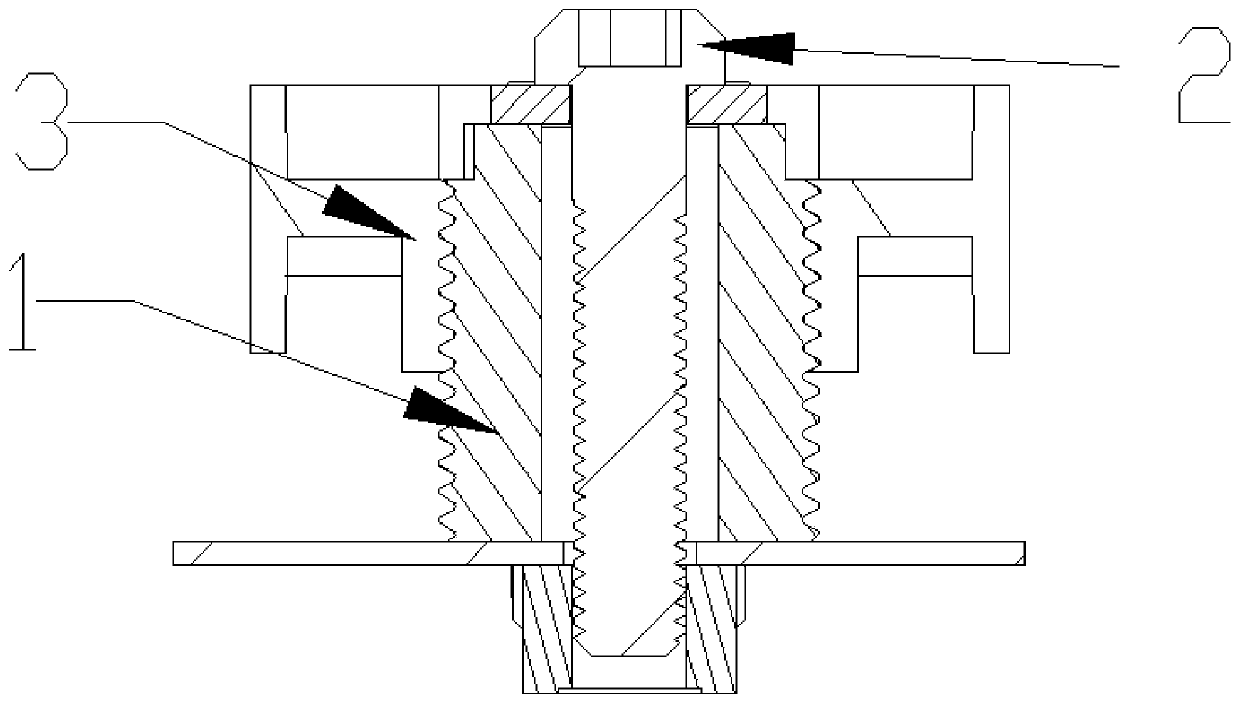

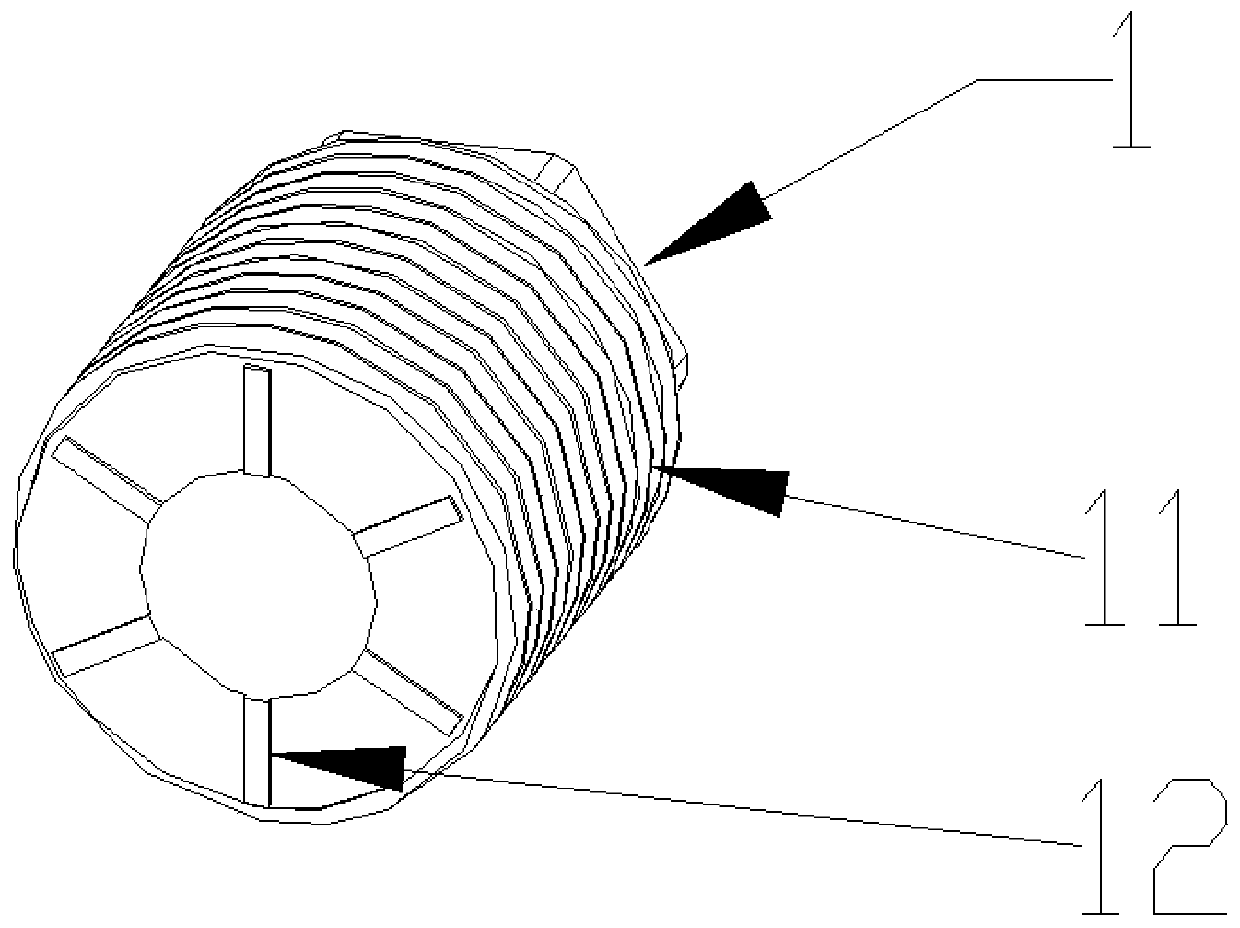

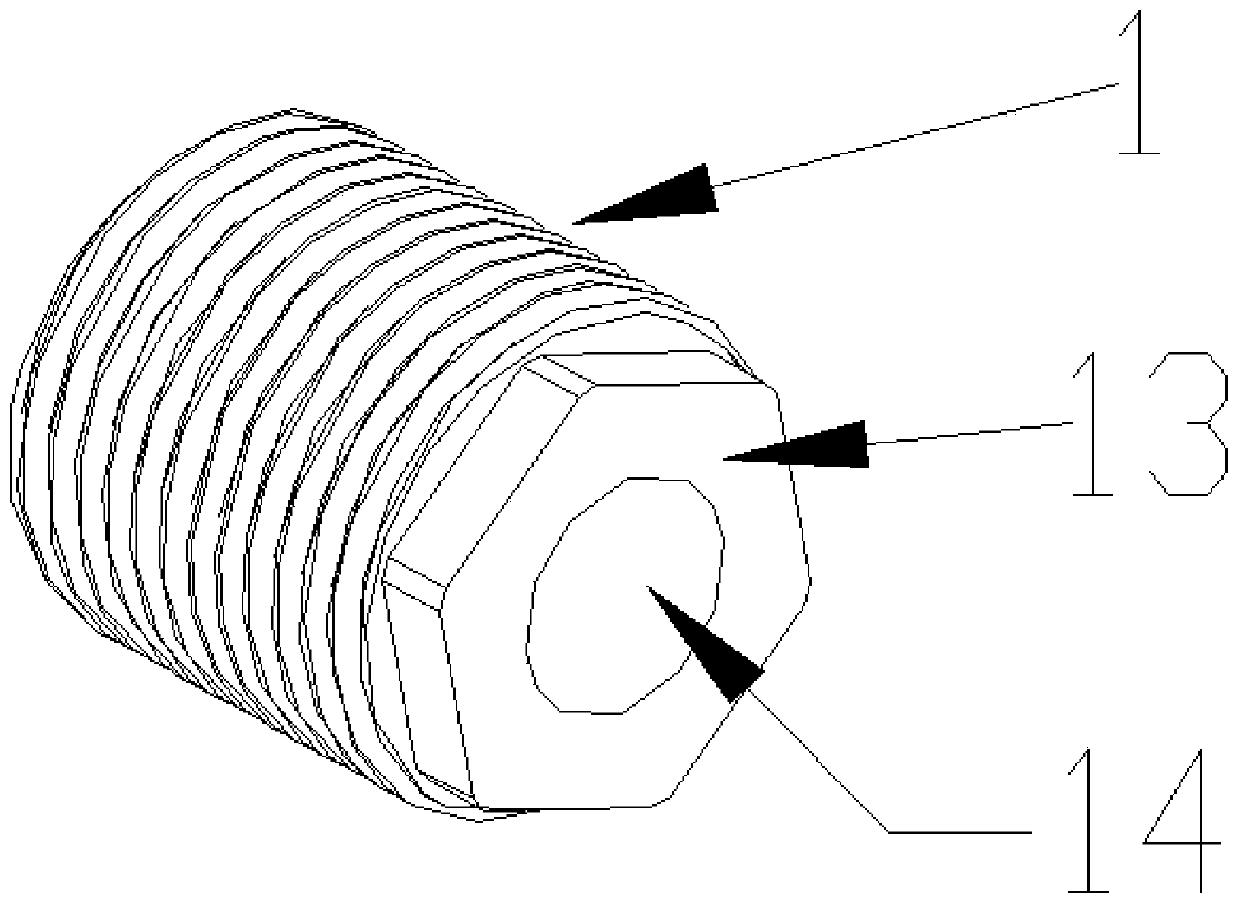

[0049] This embodiment provides a manual three-way tolerance adjuster, its structure is detailed in the attached Figure 1-10 As shown: it includes an adjusting stud 1, a bolt assembly 2 and a fixed base 3, the bolt assembly 2 includes a bolt 21 and a locking piece 22, a through hole 31 is opened in the middle of the bottom plate of the fixed base 3, and the through hole 31 is opened in the middle of the bottom plate of the fixed base 3. The inner wall of the hole 31 is provided with an internal thread 32, the outer wall of the adjusting stud 1 is provided with an external thread 11, and the top surface is provided with a boss 13; the adjusting stud 1 and the fixed base 3 are connected and fixed by thread .

[0050] Further, the adjusting stud 1 is a hollow cavity structure, the bottom end surface of the adjusting stud 1 is provided with radial patterns 12, the boss 13 has a polygonal structure, and the boss 13 has a certain height, An opening 14 with the same diameter as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com