Insulation short section for electromagnetic wave measurement while drilling system

An insulation pup joint and measurement-while-drilling technology, applied in drill pipe, drill pipe, earth-moving drilling, etc., can solve the problems of easily damaged insulation sealant, large extrusion force, insulation failure, etc., to ensure insulation and structure. Simple and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

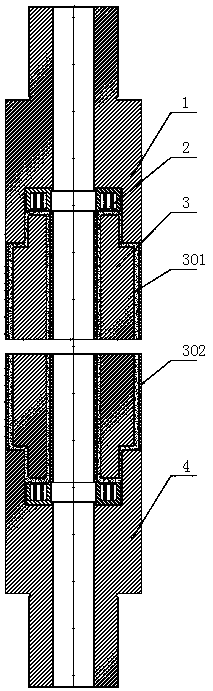

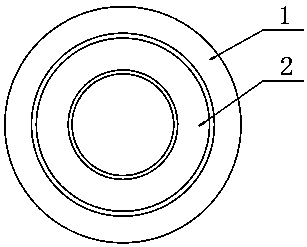

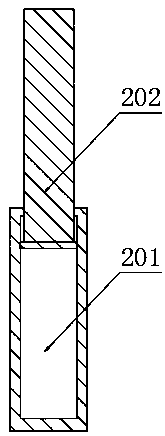

[0028] Such as figure 1 As shown, an insulating sub for an electromagnetic wave measurement while drilling system includes an insulating sub body 3 and a first protective joint 1 and a second protective joint 4 respectively arranged at both ends of the insulating sub body 3, the first protective joint 1 and the second protective joint 4 The inner wall of the second protective joint 4 is provided with a compression locking mechanism 2, the outer surface of the insulating nipple body 3 is provided with an inner wear-resistant insulating material layer 301, and the outer surface of the inner wear-resistant insulating material layer 301 is provided with an outer wear-resistant Grinding the insulating material layer 302, the inner wear-resistant insulating material layer 301 and the outer wear-resistant insulating material layer 302 are all prior art, the inner wear-resistant insulating material layer 301 can adopt wear-resistant ceramic insulating material but not limited thereto, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com